The application of laser technology has brought rapid development to different industrial fields, among which laser cutting machines are the most widely used. Laser cutting and engraving is a manufacturing process that consists of an invisible but focused laser beam that melts, burns or vaporizes material to cut or engrave patterns. People usually divide them into CO2 laser cutting machines and fiber laser cutting machines according to the difference of laser generators. These two types of laser cutting equipment are applied to different materials and different industrial fields respectively.

Fiber Laser Cutting Machine and CO2 Laser Cutting Machine

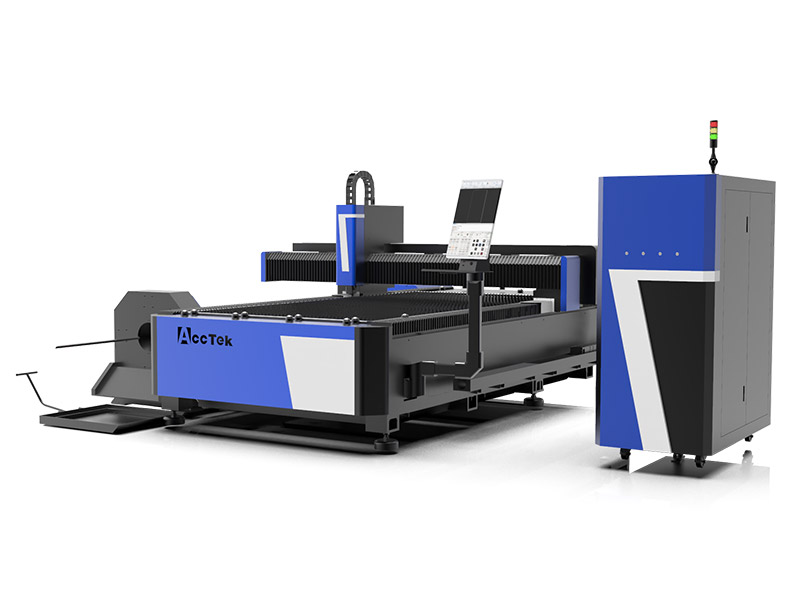

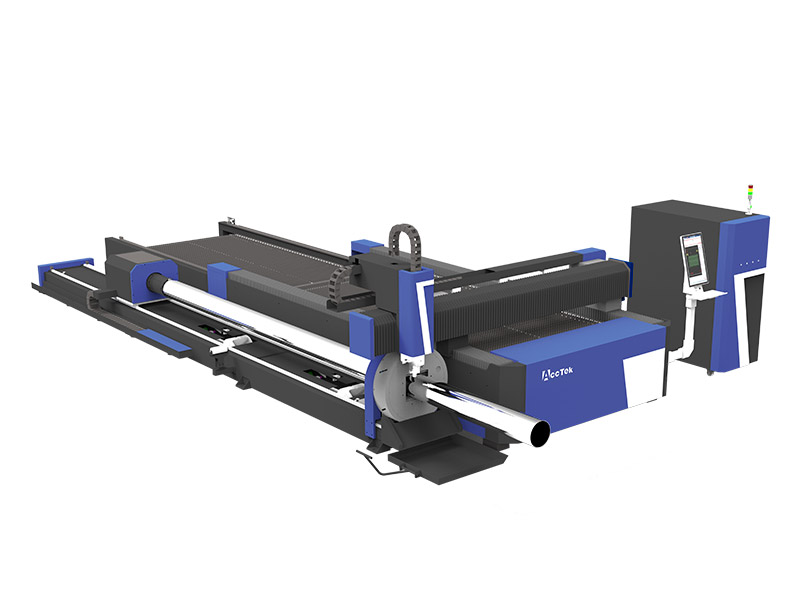

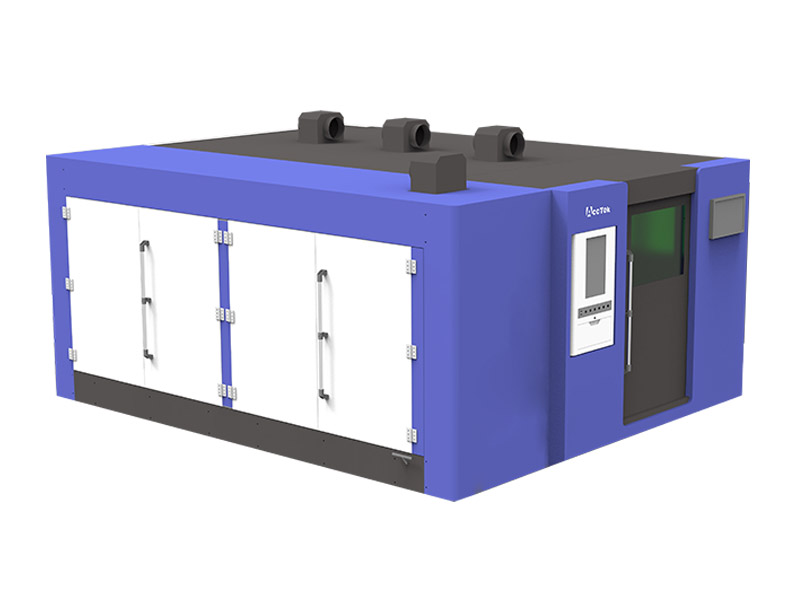

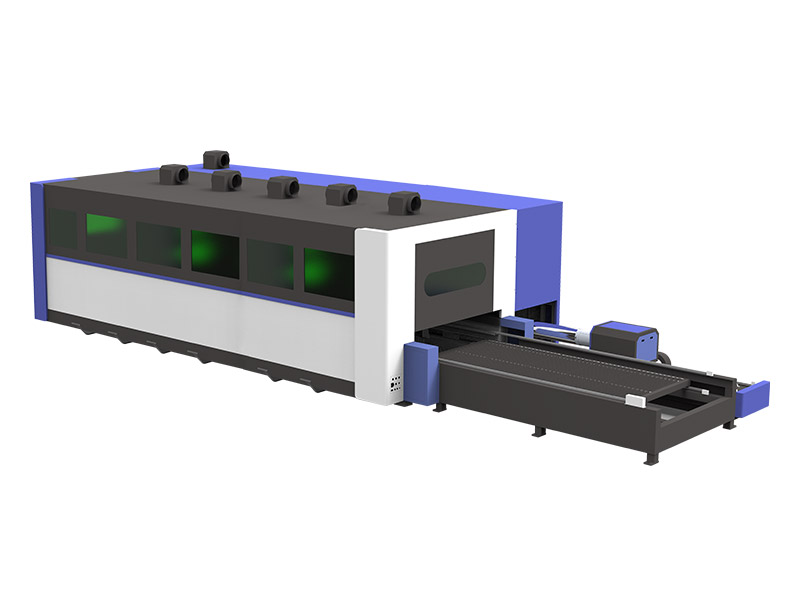

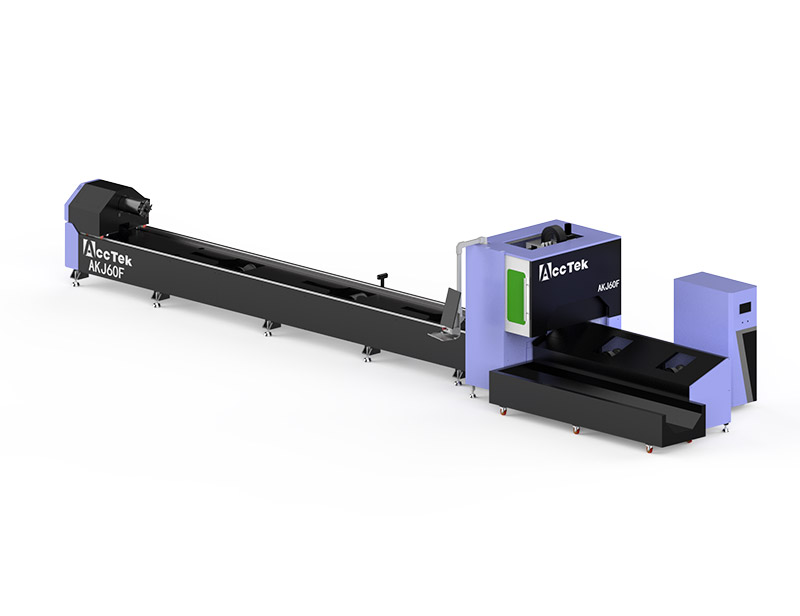

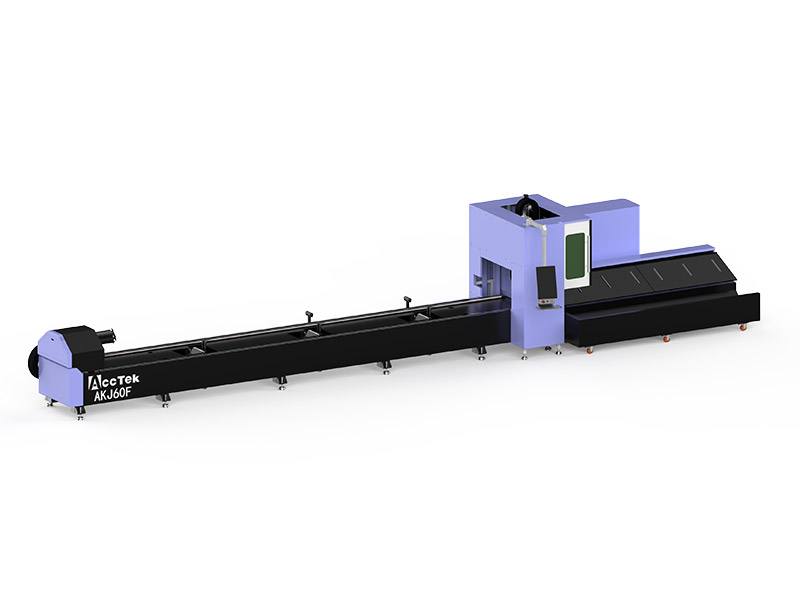

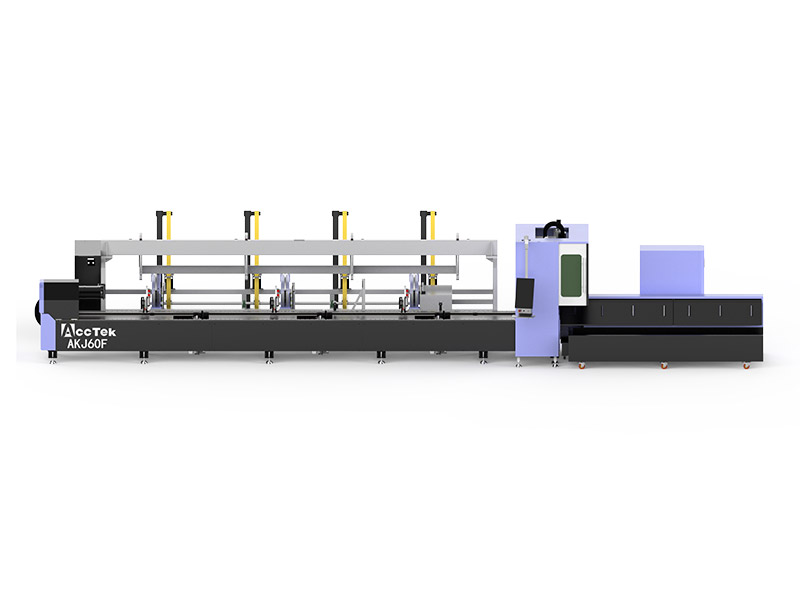

Fiber laser cutting machine is specialized in metal material processing, so it is also called metal laser cutting machine. It has high speed and high precision in sheet metal cutting and plays an important role in the metal manufacturing industry. Metal parts processed with fiber laser cutting machines do not require secondary processing, which also means manufacturers can reduce labor costs. In order to apply the processing needs of different industrial fields, currently mature laser cutting machine manufacturers can usually provide fiber laser metal cutting equipment in the power range of 1000W-30000W. As for how much laser power to choose, it depends on the type of material you need to process and the maximum thickness. Although the price of fiber laser cutting machine is higher, in the long-term use, it has lower operating cost than traditional metal cutting equipment and creates greater value for enterprises.

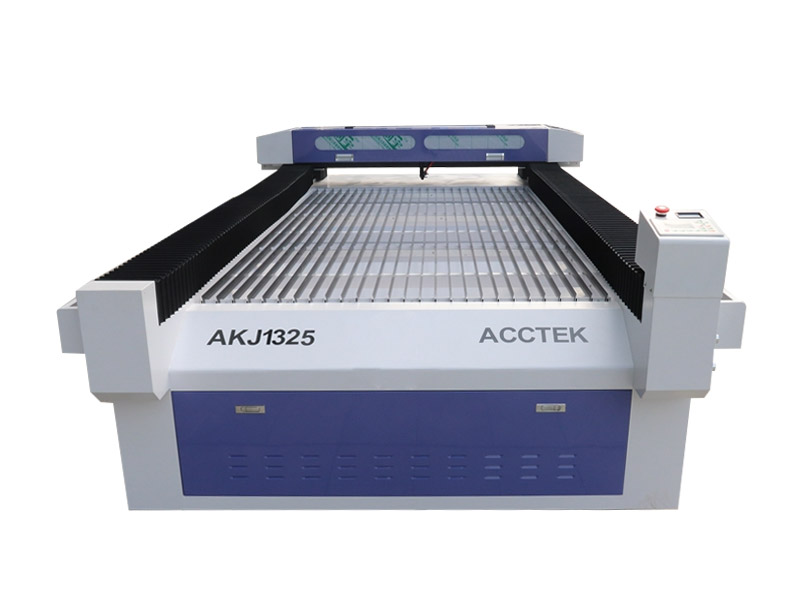

CO2 laser cutting machine is mainly used for engraving and cutting of non-metallic materials. Among them, wood and acrylic are the most common CO2 laser cutting materials, so CO2 laser cutting machines are widely used in the furniture industry and advertising industry. Besides, you can also use CO2 laser machine to cut various non-metallic materials such as fabric, cloth, leather, paper, etc. Of course, it can also engrave glass. These materials work best when engraved or cut with a laser, an inexpensive and popular laser cutting device for small businesses. It is common for beginners and even professionals to use a CO2 laser cutter to cut wood to assemble, engrave gifts, and create intricate patterns into a piece of wood.

Laser Cleaning Machine and Laser Welding Machine

In addition to the application of laser technology in the field of cutting, it has also been widely developed in the fields of metal rust removal and metal welding in recent years. In particular, the application of fiber laser cleaning machines has brought a new cleaning process to the field of industrial cleaning. Laser cleaning machines can not only be used for metal rust removal, but also for metal paint removal, metal surface oil removal, wood cleaning, rubber cleaning, plastic cleaning and other material surface pollutant removal. In addition to a wide range of cleaning materials, the laser cleaning machine also has the advantages of high cleaning accuracy, no consumables, light and easy to operate. Therefore, once it came out, it was welcomed by many enterprises.

Laser welding technology is also gaining popularity in the manufacturing of metal products as a versatile and cost-effective method of joining metallic materials. This non-contact and high power density welding process uses the energy from a laser beam to join multiple pieces of metal materials together to produce better quality products with higher production efficiency and lower cost.

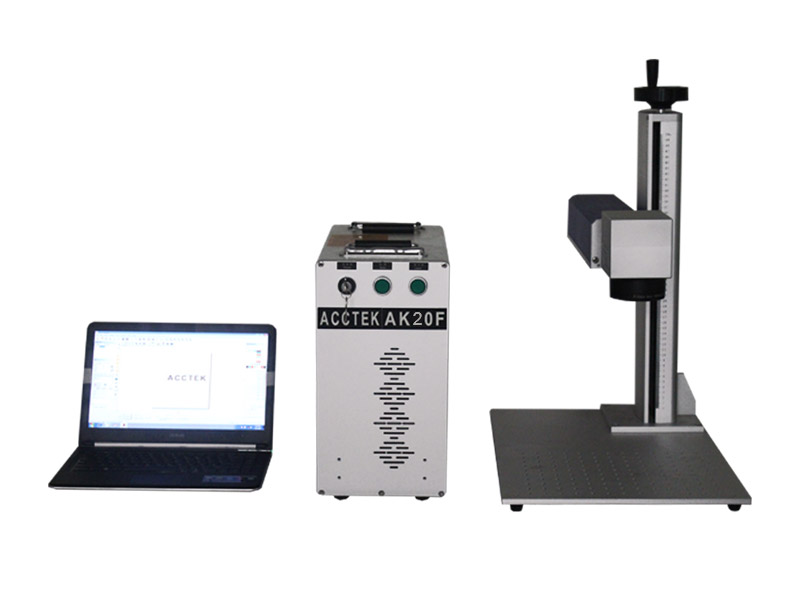

Laser Marking Machine

In addition to the above laser equipment, laser technology also plays an important role in the field of material marking. The application of laser marking technology provides manufacturers with a faster and easier way to identify and track parts. Whether it is a CO2 laser marking machine or a fiber laser marking machine, it has the characteristics of permanent marking. The marking pattern will not fall off and fade, which perfectly solves the drawbacks of the traditional marking method. Laser marking is not only flexible in processing, but also very accurate, which can greatly reduce the defective rate of marked finished products and bring greater economic benefits to users.

Our company- Jinan AccTek Machinery Company specializes in manufacturing all kinds of Laser equipment. Since 2005 we have been based in the Industrial Zone of Jinan City, Shandong Province south of Beijing. Components for our laser machines are sourced from world class suppliers and innovators in machine control. Our dedicated and highly skilled after sales service department, sales team, and thorough quality assurance procedures mean that you can buy the laser equipment you need with confidence. We welcome customers and potential business associates from around the world. We can work together cooperatively for mutual benefit.

Our business is to improve your business. Choose Acctek Machinery, life will be better.

,