Product Introduction

Types of Laser Welding Machines

-

Standard Handheld Laser Welding Machine

Rated 4.75 out of 5$3,400.00 – $16,000.00 This product has multiple variants. The options may be chosen on the product page -

Portable Handheld Laser Welding Machine

Rated 4.50 out of 5$3,700.00 – $15,500.00 This product has multiple variants. The options may be chosen on the product page -

3 in 1 Handheld Laser Welding Machine

Rated 5.00 out of 5$4,000.00 – $15,700.00 This product has multiple variants. The options may be chosen on the product page -

Double Wobble Handheld Laser Welding Machine

Rated 5.00 out of 5$3,900.00 – $16,500.00 This product has multiple variants. The options may be chosen on the product page -

Double Wire Feed Handheld Laser Welding Machine

Rated 5.00 out of 5$6,800.00 – $15,800.00 This product has multiple variants. The options may be chosen on the product page -

Air-Cooled Handheld Laser Welding Machine

Rated 5.00 out of 5$4,900.00 – $6,900.00 This product has multiple variants. The options may be chosen on the product page -

3 in 1 Air-Cooled Handheld Laser Welding Machine

Rated 5.00 out of 5$5,100.00 – $7,100.00 This product has multiple variants. The options may be chosen on the product page -

Automatic Laser Welding Platform

Rated 4.75 out of 5$9,800.00 – $21,500.00 This product has multiple variants. The options may be chosen on the product page

Application of Laser Welding Machines

Customer Testimonials

Laser Welding Machine VS Other Welding Machines

| Comparison Item | Laser Welding Machine | TIG Welding Machine | MIG Welding Machine | Stick Welding Machine | Plasma Arc Welding Machine |

|---|---|---|---|---|---|

| Heat Input | Low | Low | Medium | High | High |

| Precision | Very high | High | Medium | Low | Medium |

| Welding Speed | Fast | Slow | Fast | Medium | Fast |

| Material Distortion | Minimal | Low | Moderate | High | High |

| Joint Strength | High | High | High | Medium | High |

| Automation Compatibility | Excellent | Limited | Moderate | Low | Moderate |

| Thickness Range | Thin to thick | Mostly thin | Medium to thick | Medium to thick | Thin to medium |

| Aesthetic Finish | Clean, minimal post-processing | Very clean | Acceptable | Rough | Rough |

| Operator Skill Requirement | Low to moderate | High | Moderate | Moderate | High |

| Consumables Required | Minimal | Tungsten electrodes | Wire + gas | Electrodes | Electrodes + gas |

| Welding Method | Non-contact | Contact | Contact | Contact | Contact |

| Material Compatibility | Wide (including reflective metals) | Limited | Good for steel & aluminum | Best for steel | Limited to conductive materials |

| Portability | High (handheld options available) | Medium | Medium | High | Low |

| Operating Cost | Low (after setup) | High (due to slow speed) | Moderate | Low | High |

| Ideal Applications | Precision, automation, clean welds | Aerospace, thin metals | Structural work, fabrication | Field repairs, basic welding | Thin materials, cutting+joining |

Why Choose Us

High Precision

Our machines deliver accurate, clean welds with minimal heat input, reducing distortion and ensuring strong, consistent joints across a wide range of materials and thicknesses.

Easy Operation

Designed with intuitive controls and user-friendly interfaces, our systems allow both experienced operators and new users to achieve professional results with minimal training.

Durable & Reliable

Built with high-quality components and strict quality standards, our welding machines provide stable performance, long service life, and low maintenance requirements.

Custom Options

We offer a variety of models and customizable features to match specific production needs, helping businesses improve workflow and adapt to changing manufacturing demands.

Related Resources

What Is Laser Welding?

Explore the principles of laser welding, its benefits, applications, and how it compares to traditional welding methods. Learn how this advanced technology enhances precision and efficiency.

Frequently Asked Questions

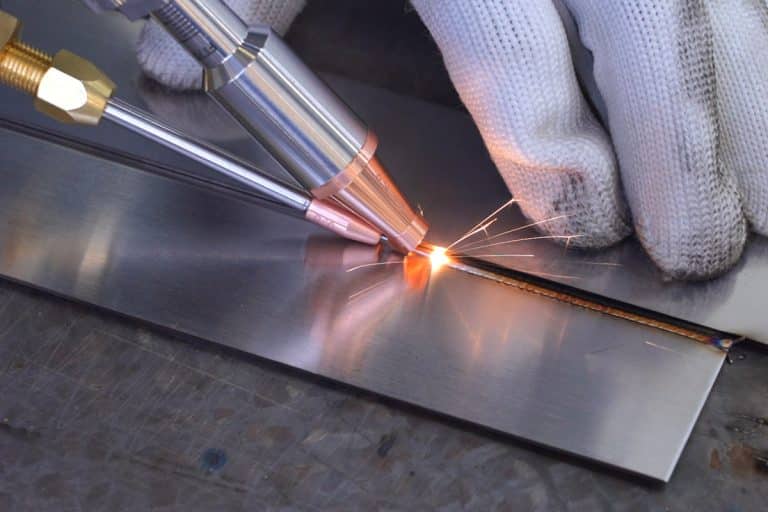

What Is Laser Welding?

The process is popular for its ability to create narrow, deep welds with minimal heat-affected zone (HAZ), making it ideal for thin materials, high-precision applications, and complex geometries. It is commonly used in industries such as aerospace, automotive, electronics, and medical device manufacturing.

Laser welding can be done with different types of lasers, including fiber lasers, CO2 lasers, and disk lasers, depending on the material and application.

What Materials Can Laser Welding Machines Weld?

- Carbon Steel: Commonly used in construction, automotive, and manufacturing industries, carbon steel is easy to weld with lasers, especially for thick sections.

- Stainless Steel: Laser welding provides precise, clean welds on stainless steel, which is commonly used in the food, medical, and automotive industries due to its corrosion resistance.

- Aluminum: Aluminum welding requires careful control of the laser due to its high thermal conductivity, but laser welding is highly effective for aluminum components in the aerospace and automotive sectors.

- Copper: Laser welding of copper requires high precision due to its high reflectivity and thermal conductivity. However, it’s often used in the electrical and electronics industries.

- Titanium: Laser welding titanium is ideal for applications in the aerospace and medical industries, as it requires a clean, controlled environment to prevent contamination.

- Brass: Used in automotive and decorative applications, brass can be effectively welded using laser technology for precise results.

- Nickel Alloys: Laser welding is highly effective for nickel alloys used in aerospace and marine applications, providing strong, durable welds for high-stress environments.

- Gold and Platinum: For high-precision applications, such as in electronics or jewelry, laser welding is used to join gold and platinum with minimal heat input, maintaining their properties.

Laser welding is ideal for a wide range of metal materials, including carbon steel, stainless steel, aluminum, copper, titanium, brass, nickel alloys, and precious metals like gold and platinum. It allows for precise, clean welds in high-performance applications.

How Do I Determine The Laser Power Required For My Welding Application?

- Material Type: Different materials absorb laser energy differently. Metals like aluminum and copper require higher laser power than stainless steel or carbon steel due to their higher reflectivity and thermal conductivity.

- Material Thickness: The thicker the material, the more power you will need. For thin materials (less than 1 mm), lower-power lasers (typically between 1000W and 1500W) are sufficient. For thicker materials, especially in the range of 5 mm or more, you may need higher power (2000W to 6000W or more).

- Welding Speed: If you need to weld at a higher speed, you will typically need more laser power to ensure the weld is formed properly before the material cools. Slower speeds allow for more time for heat to be applied, reducing the need for higher power.

- Weld Quality Requirements: If you need high-quality, clean, and precise welds with minimal heat-affected zones, you may need to use lower power with slower speeds or specialized lasers for specific tasks (e.g., small welds, jewelry).

- Laser Spot Size: The spot size affects the energy concentration. Smaller spot sizes require higher power to achieve the same weld depth as larger spot sizes. Choose a laser with an appropriate spot size for the job.

To determine the laser power required for your welding application, consider the material type, thickness, welding speed, weld quality, and laser spot size. Generally, thicker materials, faster welding speeds, and higher-quality welds require more laser power.

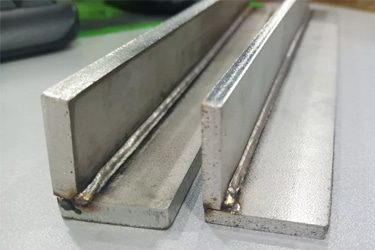

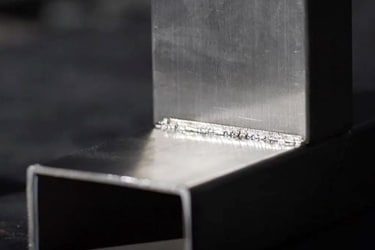

What Joint Designs Are Best Suited For Laser Welding?

- Butt Joints: Butt joints are one of the most common and effective joint designs for laser welding. The workpieces are placed edge-to-edge, creating a strong and continuous weld. This design is ideal for welding thin to medium thickness materials and provides excellent strength with minimal distortion.

- Lap Joints: Lap joints, where one workpiece overlaps the other, are also well-suited for laser welding. They allow the laser to focus on the overlap, making it easy to create a strong, clean weld. This design is useful for welding materials with different thicknesses and can be used in applications where precise alignment is important.

- T-Joints: T-joints are often used in structural and automotive applications. The laser can effectively weld along the joint where the two materials meet at a right angle. T-joints are ideal for welding medium to thick materials and provide high-strength welds.

- Edge Joints: Edge joints are commonly used for welding sheet metals and thin materials. The laser is focused along the edge of the material, making this design suitable for creating precise, narrow welds with minimal heat input.

- Flanged Joints: Flanged joints are used when materials are welded at a corner or edge. This joint design allows the laser to access both sides of the joint, making it well-suited for producing strong, clean welds with minimal distortion, especially in thicker materials.

- Corner Joints: Corner joints are used in the fabrication of frames, boxes, and other structures. When welded with a laser, these joints provide strong and durable results, especially when the materials have similar thickness.

- V-Groove Joints: V-groove joints are often used for thick material welding. The V-shape allows the laser to penetrate deep into the joint, ensuring full penetration and creating a strong bond. This design is ideal for welding materials with greater thickness or where deep penetration is necessary.

Laser welding is best suited for joint designs like butt joints, lap joints, T-joints, edge joints, flanged joints, corner joints, and V-groove joints. These designs allow the laser to deliver precise, strong, and clean welds with minimal distortion, making them ideal for a range of applications in automotive, aerospace, and manufacturing industries.

How Does Laser Welding Reduce Thermal Deformation Of Materials?

- High Precision and Focused Energy: The laser beam is highly focused, allowing the heat to be concentrated precisely at the welding point. This localized heating reduces the amount of heat transferred to the surrounding material, minimizing thermal expansion and distortion.

- Small Heat-Affected Zone (HAZ): Laser welding creates a narrow heat-affected zone (HAZ) around the weld, which means only a small area of the material is exposed to high temperatures. This limits the amount of material that undergoes thermal changes, reducing the risk of warping or deformation.

- Rapid Cooling: Laser welding typically involves rapid cooling after the laser pulse. This quick solidification of the molten weld pool reduces the time during which the material is exposed to heat, which in turn helps in maintaining the shape and structure of the material with minimal distortion.

- Lower Heat Input: Because laser welding uses a concentrated, high-power beam over a very short duration, the total heat input is much lower compared to processes like MIG or TIG welding. Lower heat input means less thermal expansion and contraction, which reduces the potential for distortion.

- Controlled Welding Speed: Laser welding allows for high-speed welding, which means the material stays under the heat source for a shorter time. This further helps to minimize thermal stresses and the likelihood of warping.

Laser welding reduces thermal deformation by concentrating the energy at the weld point, creating a narrow heat-affected zone, and rapidly cooling the material. The precision, low heat input, and high-speed welding process minimize thermal distortion, making laser welding ideal for delicate or thin materials.

What Personal Protective Equipment Is Required When Using Laser Welding Machines?

- Laser Safety Glasses or Goggles: Laser safety glasses are essential to protect the eyes from the intense laser radiation. These glasses are specifically designed to filter the wavelength of the laser being used, preventing eye injury from both direct and reflected beams.

- Protective Clothing: Flame-resistant, non-reflective clothing should be worn to protect against sparks, hot metal, and radiation. Long-sleeve shirts and pants, preferably made from thick cotton or specialized materials, are recommended to avoid burns.

- Gloves: Heat-resistant gloves are necessary to protect the hands from burns or heat exposure when handling metal parts during or after welding. For laser welding, gloves should also be designed to allow dexterity while offering sufficient heat protection.

- Welding Helmet or Face Shield: A welding helmet or face shield is needed to protect the face from intense light, radiation, and flying debris. These shields should be fitted with a lens that filters out harmful radiation, providing additional eye and facial protection.

- Respiratory Protection: If adequate fume extraction is not in place, respirators or dust masks with the appropriate filters (such as N95 or P100) should be worn to avoid inhaling harmful fumes, gases, or particulate matter generated during the welding process.

- Hearing Protection: High-powered lasers can generate loud noises during welding, especially in industrial environments. Earplugs or earmuffs may be necessary to protect hearing from prolonged exposure to high noise levels.

- Safety Footwear: Sturdy, steel-toe boots are recommended to protect the feet from falling equipment, sparks, and molten material that could cause injury.

Personal protective equipment (PPE) includes laser safety glasses, protective clothing, heat-resistant gloves, welding helmets, respiratory protection, hearing protection, and safety footwear to safely operate laser welding machines. This gear helps protect against laser exposure, heat, fumes, and physical hazards associated with welding.

Is It Necessary To Use Gas When Using Laser Welding?

- Shielding Gas

- Purpose: The most common reason for using gas in laser welding is to shield the weld area from contamination by atmospheric gases like oxygen or nitrogen.

- Common Gases Used: Argon, helium, nitrogen, and sometimes CO2 are typically used as shielding gases. Argon is the most common as it provides an inert atmosphere, reducing the risk of oxidation and porosity in the weld.

- Gas for Cooling

- Purpose: Some laser welding applications require a cooling gas to help control the heat distribution, especially when working with heat-sensitive materials like aluminum or titanium.

- Common Gases: Compressed air or nitrogen can be used to reduce excessive heat buildup and ensure proper cooling.

- Active Gases for Specific Applications

- Active gases like CO2 may be used in certain situations to promote chemical reactions during welding, such as cleaning oxides off the surface of metals or promoting specific weld properties.

- When Gas is Not Necessary

- In some laser welding setups (especially for high-precision or small-scale welding), using gas may not be necessary, particularly when working in controlled environments with minimal risk of contamination.

- For metal-to-metal welding in vacuum chambers or when working with low-alloy steels, gas may not be required.

While gas is not strictly necessary for all laser welding applications, shielding gas is often used to protect the weld area from contamination, especially when welding metals like steel or aluminum. Gas can also be used for cooling and improving weld quality, but in some controlled settings, laser welding can be performed without gas.

What Are The Recommended Environmental Conditions For Laser Welding Machines?

- Temperature

- Optimal Range: The ambient temperature in the welding area should generally be between 18℃ to 25℃ (64℉ to 77℉).

- Avoid Extreme Temperatures: Extreme heat or cold can affect the performance of the laser and the material being welded. High temperatures can increase the risk of thermal distortion, while cold temperatures may cause poor weld penetration.

- Humidity

- Ideal Humidity: Humidity levels should be kept between 40% and 60%.

- Why it Matters: High humidity can cause condensation on equipment, leading to rust or electrical issues. Low humidity can cause static build-up, which can interfere with the precision of the laser.

- Ventilation and Air Quality

- Fume Extraction: Proper ventilation or fume extraction systems are essential to remove harmful fumes, gases, and particles created during the welding process.

- Clean Air: Ensure the workspace is free from dust, smoke, or airborne contaminants that may interfere with laser operation or damage sensitive components.

- Vibration Control

- Stable Environment: The welding area should be as free of vibrations as possible. Even slight vibrations can affect the precision of the laser, leading to poor weld quality.

- Proper Foundations: Ensure the laser machine is mounted on a stable, vibration-resistant surface to minimize movement during welding.

- Lighting

- Proper Lighting: The area should be well-lit but free from direct bright lights that could interfere with the laser beam’s accuracy.

- Avoid Reflections: Ensure the workspace is designed to minimize reflective surfaces that could redirect the laser beam and cause accidents.

- Cleanliness of the Workspace

- Dust-Free Environment: The work area should be kept clean and free from dust and contaminants. These could affect both the quality of the weld and the performance of the laser optics.

- Electrical Stability

- Consistent Power Supply: The area should have a stable electrical supply to avoid power surges, which can damage the laser system.

- Surge Protection: Install surge protectors to prevent damage from power fluctuations.

The recommended environmental conditions for laser welding machines include stable room temperature (18℃ to 25℃), 40-60% humidity, good ventilation, vibration control, clean and consistent lighting, and a dust-free environment. A stable power supply is also crucial to ensure the safety and effectiveness of the machine.

Get Laser Welding Solutions

We’ll help you choose the right equipment, get it up and running fast, and support you every step of the way. Our team understands the real-world challenges of welding, and we’re here to make it easier, cleaner, and more productive. Talk to us today and get a laser welding solution that fits your operation—no guesswork, just results.