CNC router machine is the basic wood equipment for panel furniture manufacturing. It can complete various processes such as engraving, cutting, drilling, and milling. With the advancement of technology, the functions of woodworking CNC router machine are more complete and the carving is more fine. It not only saves labor costs, but also improves work efficiency. CNC router machine has irreplaceable advantages in processing panel furniture.

1. Improve work efficiency

Panel furniture takes a lot of time to cut and engrave panel patterns by hand. And if it is a CNC router machine to process panel furniture, the panel cutting and pattern engraving can be completed in a few minutes. This greatly improves the production efficiency and can produce more furniture panels in the same time.

2. Save labor cost

The woodworking CNC router machine has a high degree of automation, and the operation can be completed by one person. Dedicated cutting software is easy and quick to use, allowing you to customize furniture according to customer requirements without the need for a designer. The amount of work that a CNC cutting machine can complete in one day is equivalent to the work done by multiple woodworkers, which can save more labor costs for the workshop.

3. High cutting precision

The data processing of

CNC router engraving machine is more accurate and fast, and the machine equipment runs stably. Proper use of the machine ensures that each batch of furniture panels is processed with complete consistency and no errors.

4. Has higher security

The woodworking CNC engraving machine can realize functions such as intelligent typesetting, automatic cutting, punching, slotting, etc. It does not require manual contact with the plate for production during the production and cutting process, and has higher safety.

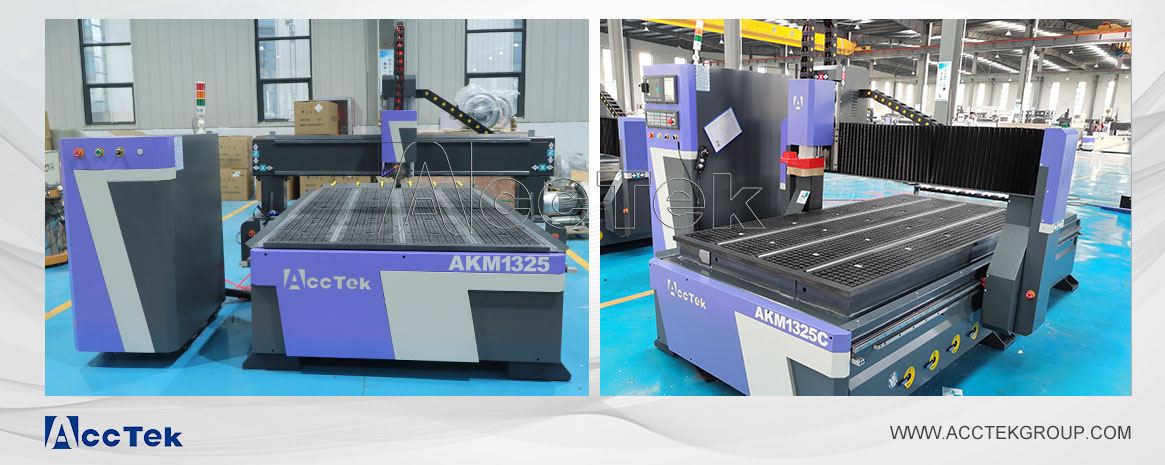

CNC router machine AKM1325 is a basic woodworking processing equipment. The size of the worktable is 4×8ft, which can meet most of the furniture board processing needs. Equipped with Mach 3 control system, there are USB ports and Ethernet ports, it can be connected to a computer, and it supports Winxp Win7 Win10 system, no need to install additional drivers, and the operation is simple.

A feeding auxiliary wheel is added at the rear of the machine. When processing large-area plates, the auxiliary wheel can be used for feeding, which reduces the labor intensity of workers and improves work efficiency. The X and Y axes are driven by a helical rack and pinion, so that the gear meshing degree is higher and the precision is higher. The guide rail chooses the Taiwan Hiwin square rail, which has better load-bearing capacity compared with the round rail.

If you are a large furniture manufacturer and need higher work efficiency, you can choose a CNC router machine with auto tool changer. The

ATC CNC router machine produced by ACCTEK factory is equipped with 9.0KW ATC spindle, which has higher precision and faster speed. The equipped auto tool changer can load 4-12 tools and complete the automatic tool change in seconds, saving more time.

If you want to expand the market in the furniture industry, a CNC router machine with excellent performance is essential equipment. Want to know which one is more suitable for your workshop, communicate online now.