One of the advantages of

fiber laser cutting machine is that the energy density of the laser beam is high, so the diameter of the focal point is small, so that the cutting seam is small when cutting metal. When operating a laser cutter, the smaller the focal depth of the focusing lens, the smaller the diameter of the focal spot. Therefore, when cutting metal, it is very important to control the position of the focus and the surface of the cut material in order to obtain a high-quality, high-precision finished product.

When cutting sheet metal with different thicknesses, in order to achieve a perfect cutting effect, the focus of the laser beam needs to be set at different positions, which is called focus control.

In the early application of fiber laser cutting machine, the laser head could only rely on manual focusing. Manual focusing has high requirements on the technical level of the operator, and if the operation is improper, it will affect the accuracy and production efficiency of the product. With the development and maturity of laser technology, auto focus laser heads were invented, and manual focus laser heads were gradually eliminated. This is what we often call a

laser cutting machine with autofocus.

What is the difference between manual focus cutting head and automatic focus cutting head?

The perforation focus of the manually-adjusted cutting head cannot be adjusted, and the perforation focus is consistent with the cutting focus. When perforating thick plates, the energy is insufficient and the perforation speed is slow. The auto-focusing cutting head can automatically adjust the focus when perforating, adjust the focus size when perforating, increase the perforating energy, and increase the perforating speed when perforating thick plates.

From the point of piercing time, under the condition of obtaining the same cutting effect, the speed of automatic focusing cutting head is half of that of manual focusing. At the same time, autofocus will reduce the over-melting phenomenon of sheet metal caused by the short material overheating time, and the advantages are very obvious.

The auto focus fiber laser cutting machine can significantly improve the production efficiency and greatly reduce the perforation time for cutting thick metal sheets. When processing metal workpieces of different materials and thicknesses, the machine can quickly adjust the focus to an appropriate position. Therefore, the autofocus function is important and indispensable for high-speed laser cutting tools.

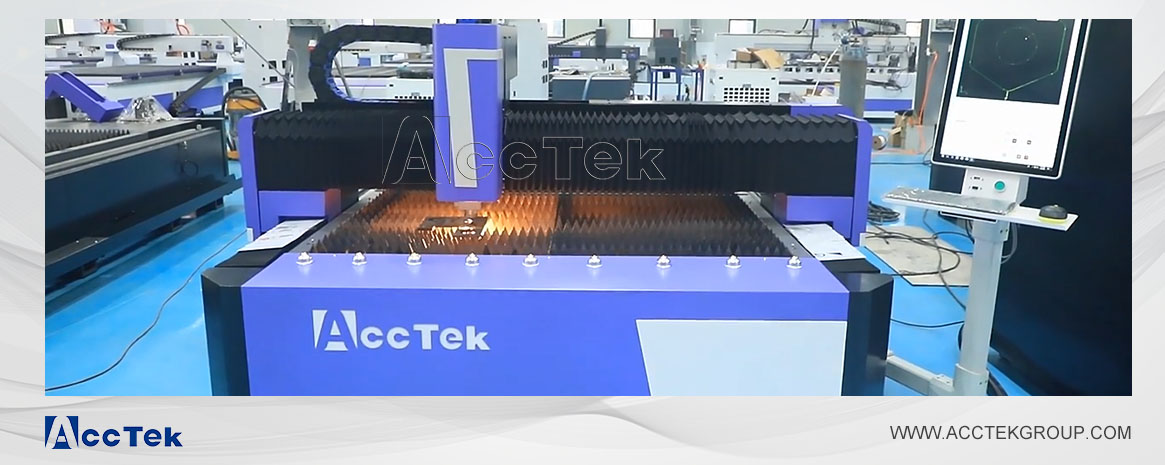

All

fiber laser cutting machines produced by ACCTEK factory are equipped with auto focus laser head. The machine can quickly change different focal lengths to adapt to the processing of metal plates of various thicknesses. By using the autofocus function, you can quickly and accurately complete metal piercing and cutting, increasing workshop productivity.