Laser metal cleaner has been well used in today's industrial field. You can often see videos on YouTube of using lasers to remove rust, paint, and other contaminants. These videos demonstrate the effectiveness and efficiency of laser cleaning. With the development of laser technology, other laser cleaning technologies such as laser rust removal are also constantly developing.

Laser cleaning machines come in a variety of specifications, before introducing them to you, let’s first understand how laser cleaning works. Laser cleaning technology applies laser focused energy to the area of the material surface that needs to be cleaned. When the laser interacts with the contaminants, the surface contamination layer is removed and the inner clean material surface is exposed.

In the field of laser cleaning, continuous laser cleaning machines and pulsed laser cleaning machines are used in different cleaning markets. For emerging laser cleaning applications, different opinions have emerged as to whether continuous or pulsed laser cleaning should be used. There are also two types of laser cleaning equipment using pulsed and continuous lasers in the laser market. Next, I will introduce the difference between them so that you can better choose a laser cleaning machine.

Pulse laser cleaning machine

The 100W pulsed laser cleaning machine can better control the heat input and prevent the substrate from being slightly soluble due to excessive temperature. Therefore, it is often used to clean high-precision workpieces. For this type of laser cleaning machine, the speed is not the most important, the cleaning effect is fine and the substrate is not damaged is more required by the user.

Pulse 100W laser cleaning machine application field

Restoration of historical relics

precious artwork

precision instrument

expensive jewelry

Any product that requires gentle cleaning

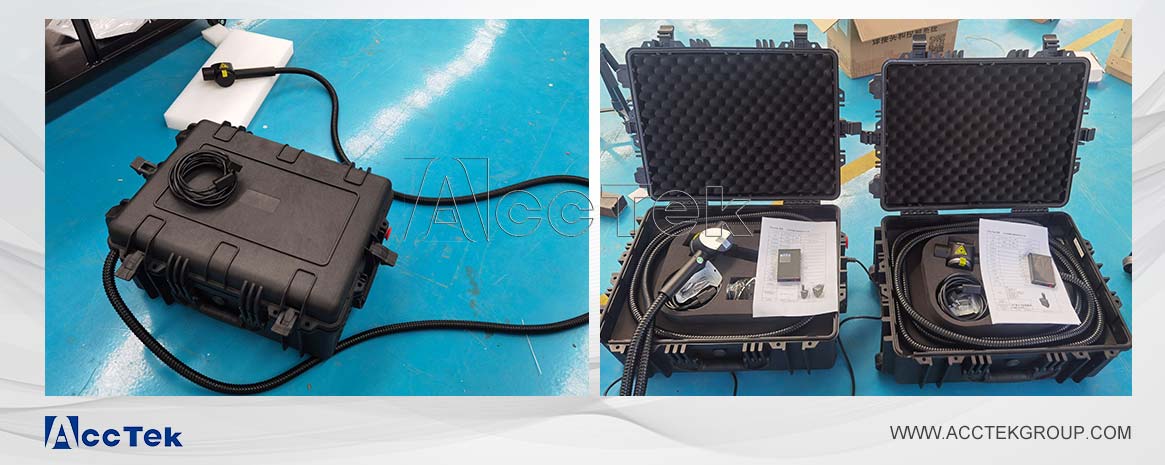

100W laser cleaning machine is a portable laser cleaning machine. With a trolley case design, you can easily carry it from one place to another. It's perfect for cleaning items away from the production or repair line. The inside of the chassis is filled with hard sponge. While fixing the parts of the laser cleaning machine, it has a buffering effect on the impact of foreign objects and protects the machine from damage.

Higher precision determines the more expensive pulse laser cleaning machine. The 100W laser cleaning machine price is often more than 10,000 US dollars, and the 300W laser cleaning machine price is more than 30,000 US dollars. The higher the machine power, the more expensive the price.

Continuous laser cleaning machine

ACCTEK continuous laser cleaning machines are available in a power range of 1000W to 2000W. This high-power laser cleaning machine is currently the mainstream equipment in the field of industrial cleaning. High power means faster and more efficient cleaning. This type of laser cleaning machine is suitable for large area rust removal and paint removal. The material to be cleaned has a large heat dissipation block, and the requirements for damage to the substrate are not high.

Continuous laser cleaning machine application field

Laser removal of old car paint

Laser wall graffiti removal

Laser removal of mold oil

Laser Removal of Rail Rust

Laser cleaning welds

High-power laser cleaning machine is the most widely used in rust removal, so it is also called laser rust removal machine. It can clean rust on any equipment, including agricultural machinery, construction machinery, automobiles, iron frames, iron fences, pipes, etc. This industrial laser rust removal machine is also designed with a hand-held laser cleaning gun, which is easy to operate.

The continuous laser cleaning machine has a price advantage. The cheapest price for a

1000W laser rust remover machine is only $7,100, and even a 2000W IPG laser rust removal machine costs only $26,900. Compared with pulsed laser cleaning machines, they are more suitable for industrial cleaning.

Regardless of the type of laser cleaning machine, they all have unique cleaning advantages, which is why laser cleaning is becoming more and more popular.

1. The laser beam can achieve precise positioning and precise cleaning without affecting other surrounding areas.

2. Laser rust removal does not require other media such as chemicals, no consumables, no chemical pollution, and is more environmentally friendly.

3. Simple operation and no complicated process settings. After simple training, the staff can be on duty quickly.

4. The laser cleaning system is stable and requires almost no maintenance, reducing operating costs.

5. High cleaning efficiency. Regardless of the type of laser cleaning machine, its cleaning efficiency is much higher than that of traditional cleaning methods.

Although the laser cleaning machine/laser rust removal machine is safer, the emitted laser will cause certain damage to the retina and cornea. Therefore, it is necessary to always wear laser protective glasses when performing laser rust removal. In addition, after turning on the power, do not look directly at the light hole of the laser cleaning gun. The industrial laser cleaners provided by ACCTEK include laser safety goggles, so you do not need to repurchase them.

There are different types and powers of laser cleaning machines to choose from. But the most expensive is not necessarily the most suitable for your cleaning needs. You need to consider a variety of factors such as cleaning material type, cleaning speed requirements, portability, and more to choose the best budget laser cleaner. We hope these sharings will help you determine the best laser cleaning machine for your business in 2022.

If you are buying a laser cleaning machine for the first time and don't know what to choose, you can contact our team of experts online. We will guide you to the best laser cleaning machine based on our expertise and experience.