Everyone knows about CNC cutting machines very well. Many of the products we usually use need to be cut before they can be processed into products. Among these CNC cutting machines, there is a machine with a relatively high technical content, that is, a

CNC laser cutting machine. There may be some friends who have seen this kind of laser cutting machine, and it is generally used in some large processing plants. So in which industries will this laser cutting equipment be used? Today, I will introduce to you what different industries use this laser cutting machine for?

CNC laser cutting machines are used more in the field of engineering machinery processing. There are a lot of construction machinery that will have a lot of round holes or square holes, and some construction machinery may have some special-shaped holes. These holes need to be processed by cutting, and then they need to meet certain precision requirements when cutting. Then at this time, you can use this CNC metal laser cutting machine. Using this laser cutting equipment, it is easy to cut out the desired ideal shape and the cutting speed is very fast, and the cutting accuracy can also be effectively guaranteed. Therefore, this kind of cnc metal laser cutting equipment will be widely used in the construction machinery processing industry.

In addition to being used in the field of construction machinery, CNC laser cutting machines are actually used more in one industry, that is, in the shipbuilding industry. For example, when building ships, there are many large pieces of steel to be cut into small parts. In addition, the quality of the cutting seams of these cuttings is particularly high when cutting. And it is also required that the cutting surface be kept vertical or the cutting surface is required to be particularly smooth. Generally, it can be put into use immediately after cutting and does not require secondary processing. In this case, metal laser cutting equipment with particularly high precision and relatively simple and easy operation is required.

In addition to the use of such fiber laser cutting machine in the field of shipbuilding, this equipment will also be used in the fitness equipment production industry. There are actually many specifications and different models of this metal laser cutting equipment. In the production and processing of fitness equipment, some parts of fitness equipment are more complicated in shape. That requires special flexibility when cutting to handle the shape and size of these pipes or metal sheets. Therefore, the use of tube laser cutting machine in the fitness equipment manufacturing industry is particularly effective. After using the laser cutting equipment, the production efficiency of the fitness equipment is greatly improved, thereby indirectly reducing the production cost of the fitness equipment. This allows us to buy affordable fitness equipment on the market.

CNC laser cutting machines are also used in a special industry, and this industry is also an industry that everyone can easily think of. This is the car manufacturing industry. In the manufacture of automobiles, a large number of metal parts are used and the precision of these metal parts is very high. For example, in the production of automobiles, it is necessary to produce doors and brake pads. These things all have higher precision requirements and higher production efficiency requirements. After using fiber laser cutting machine, the effect of improving efficiency and ensuring accuracy can be well achieved. Of course, other industries will also use this machine, such as the kitchenware production industry, the advertising industry, and the sheet metal processing industry.

The application industry of CNC fiber laser cutting machine is very wide. It can be said that as long as there is a need for metal cutting, the laser cutting machine is inseparable. However, there are many types of metal laser cutting machines, and different industries have different needs, so it is necessary to choose the laser cutting equipment suitable for the production of enterprises. The following introduces four CNC fiber laser cutting machines for you, which are suitable for different business needs. You can buy the most valuable laser cutting equipment within the best budget.

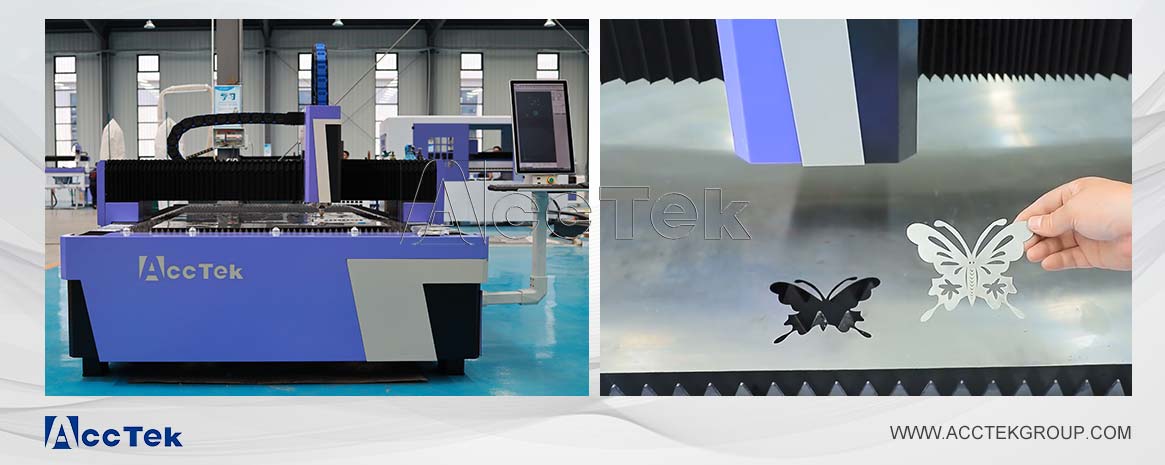

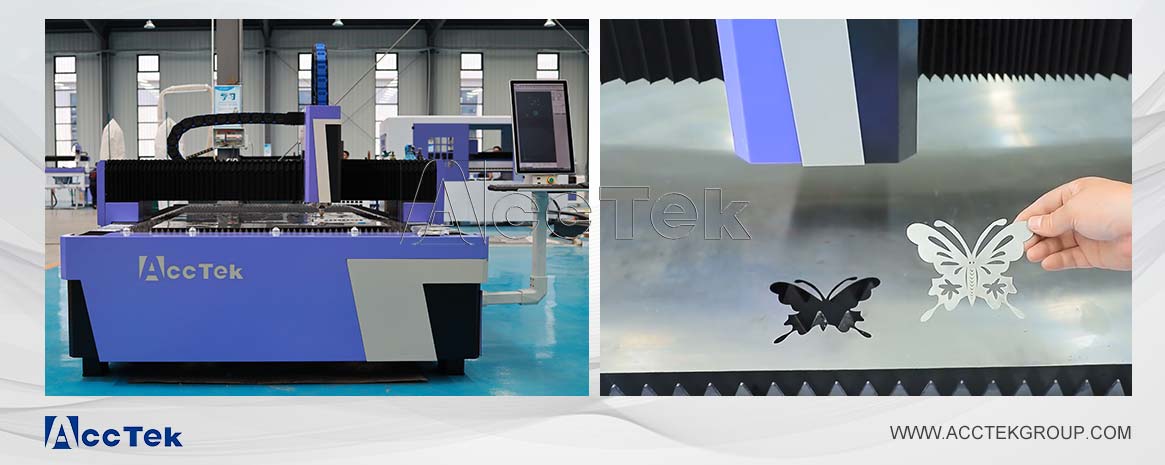

This is an affordable industrial flat-panel fiber laser cutting machine with a laser power range of 1000W-2000W to choose from. It is a professional CNC laser cutting equipment for metal plate cutting and hollowing out. The gantry adopts a newly designed aviation aluminum casting, which replaces the welded steel gantry, which is lighter and makes the machine run faster. Equipped with an auto-focusing laser cutting head, it can not only improve work efficiency, but also avoid mistakes caused by manual focusing and ensure the accuracy of metal cutting.

This sheet metal fiber laser cutting machine is suitable for industrial fields that need to cut flat metal, such as elevator manufacturing, ship industry and so on.

This is a professional CNC laser cutting equipment for cutting metal pipes, which can cut and hollow out any shape on metal pipes. The high flexibility of the laser pipe cutting machine provides strong technical support for more and more personalized metal customization, reduces the number of molds used, and greatly reduces the cost of enterprises.

CNC metal tube laser cutting machine can cut round tubes, square tubes, rectangular tubes, channel steel, hexagonal tubes and other special-shaped tubes. It is suitable for industrial fields such as fitness equipment and industrial pipes that require a large number of metal pipes to be cut.

This is a multifunctional CNC laser cutting machine, which has the dual function of cutting metal pipes and metal plates. It can not only save the cost of purchasing two laser equipment, but also save the space in the workshop. It is suitable for industries that need to cut both sheet metal and metal tubes. For example, door panel machining and exhaust pipe machining in the automotive industry.

This is a compact entry-level metal laser cutting equipment with a fully enclosed design, which is conducive to smoke exhaust and is more environmentally friendly. This small fiber laser cutting machine is more suitable for businesses or hobbyists who produce small metal workpieces. It can process metal signs, hardware, lighting, metal ornaments and other items.