A good

CNC router will increase your woodworking output and enable you to create spectacular sculptures, otherwise manual completion would be difficult. With a CNC router, you can create almost anything you can imagine. Configure the CNC router to be cut and formed on wood, plastic, aluminum, or other materials. In a few minutes, the device will carve the pattern or design you want on the wood. However, not all CNC routers have the same effect. Different machine configurations will have different functions, so choosing a machine that suits your work needs will bring you greater benefits.

CNC stands for computer numerical control, which refers to machines operated by computer software and electronic devices. A wood CNC router is an automated equipment that can be used for cutting and milling wood products. These machines can be used to cut and carve different materials such as wood, metal, glass, plastic, etc. You don't need to control the spindle of the fixed tool manually, but let the machine complete it for you. CNC machine tools come in various shapes and sizes. Before spending money to buy a machine, it is important to ensure that you have the appropriate specifications and types of machines that are very suitable for your needs. The following are the key contents to search for in the CNC wood router.

1. Software

When purchasing CNC router machines, it is necessary to check the software that powers the CNC router. The last thing you want to buy is a machine that is incompatible with your computer system, or a machine that is too technical for anyone to use. Consider the software requirements for CNC routers. Although wood CNC machines are controlled by computers, not every computer system can operate them. Modern CNC routers have been created to run Windows, Mac OS, and Linus operating systems. Therefore, choose a CNC that can run on your preferred operating system.

2. Spindle

Woodworking does not require too much torque, but having a high rotational speed can achieve faster cutting speed. That is to say, do not compromise too much on power, as it will affect the smoothness of the product. Please note that very high speeds and insufficient feed rates can also affect the quality of wooden products.

3. Drive system

Check the drive system used by the machine. You must choose between two drive systems in modern CNC machine tools: screw drive or rack drive.

Spiral transmission - This is the most basic transmission system, characterized by slow speed and short service life. If installed incorrectly, the screwdriver may occasionally loosen and need to be tightened. This drive system is typically used for smaller engraving projects.

Rack Drive - The rack drive has faster speed, higher efficiency, and longer service life, making it an ideal choice for wood carving projects with higher requirements. Compared to screw transmission, this type of transmission provides more precise transmission and is also more expensive. Since the rack drive provides more accurate transmission, it can be used on the laser module to obtain sufficient engraving depth.

4. Motor system

CNC router machines usually use servo motors or stepper motors to drive their axes. Servo motors run faster than stepper motors and typically have more consistent torque throughout the entire speed range of the machine. These motors can also withstand high speeds and can cut wood more accurately than stepper motors. Due to these reasons, servo motors are most suitable for large or commercial applications that require improved positioning accuracy. On the other hand, stepper motors are a more affordable choice and an ideal choice for basic flat surface engraving. They are also easy to use and reliable, making them an ideal choice for regular woodworking projects

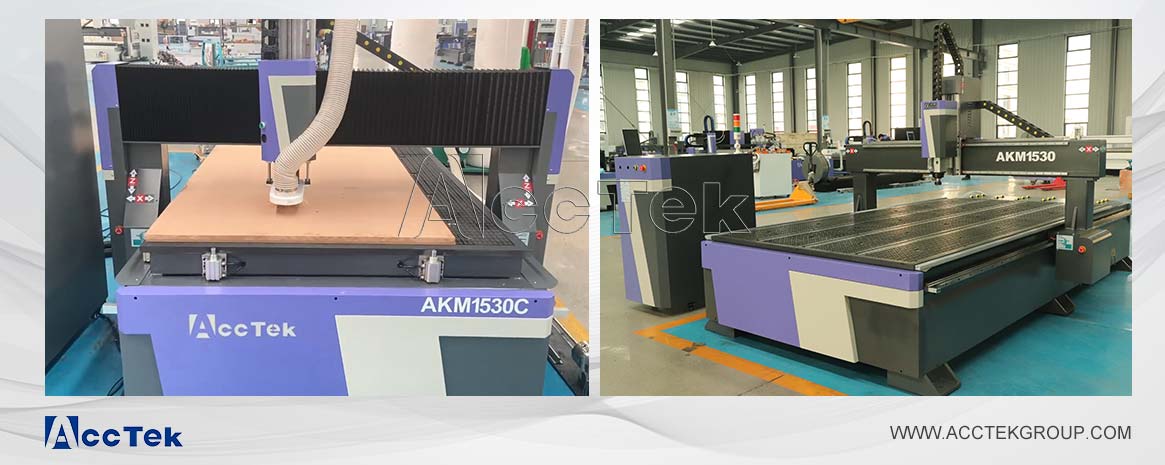

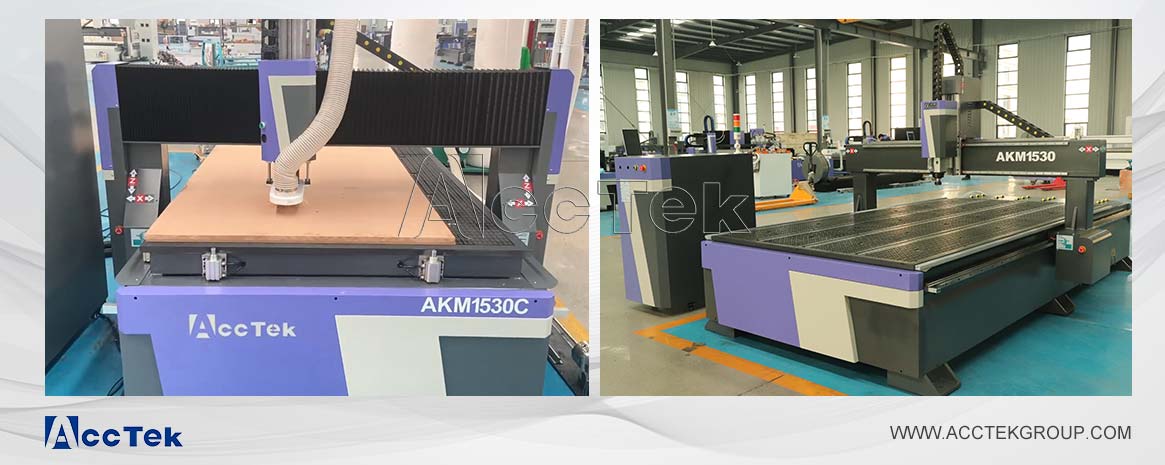

5. Work area

Woodworking usually involves handling large workpieces. Therefore, it is important to consider a machine that can accommodate workpieces. Most machines allow you to use an extended workbench or external support to handle long workpieces, but the width of the workpiece may be a limiting factor.

6. The Axis

Should you purchase a 3-axis, 4-axis, or 5-axis CNC router machine? This will depend on the nature of the work you plan to perform using the machine. Simple and high-capacity parts are most suitable for

3-axis CNC routers. Or if you are drilling shallow holes, cutting keyways, or simply polishing surface features, you only need a three-axis machine tool.

4-Axis CNC router machine tools can make your work easier, especially when machining cylindrical shapes. If you need to cut the same markings on each surface of the block, a 4-axis CNC router machine can simplify the work for you and save you the trouble of reinstallation.

5-Axis CNC routers are the best and most advanced CNC machine tools today. These machines are very suitable for highly complex disposable parts that require high-quality processing. They can present extremely complex designs in one operation. But their prices are also very high.

In the past, precise and beautiful prints were all handmade, which was a time-consuming task and often not as accurate as people hoped. Fortunately, we now have CNC routers that can produce accurate and outstanding sculptures in a short period. By using CNC routers, you can save a lot of time and create high-quality products. Start using a CNC router to create a woodworking plan, contact us and get a free CNC machine customization plan.