Metal equipment or workpieces of metal materials will rust when exposed outdoors for a long time. In order to ensure their normal use, they need to be derusted. So which rust removal method is more effective and less expensive? This article introduces you to the comparison of several rust removal methods.

Of course, there are many ways to remove rust. For example, mechanical friction can be used to remove rust, chemical agents can be used to remove rust, and dry ice cleaning can be used to remove rust. In addition, there is another way to remove rust is to use a

laser cleaning machine to remove rust. There are so many ways to remove oxidized components from metal surfaces, so which one is better? In fact, it is more popular to use laser to remove rust. Let's analyze why you should use laser instead of other methods.

The reason why the laser rust remover is chosen by more and more users is mainly because of the obvious advantages of laser to remove rust. If we use sandblasting to remove rust, since the cleaning medium is in direct contact with the metal surface, it will cause friction damage to the metal surface, which will have a certain impact on the use of the workpiece. In some cases, more waste may be generated due to sandblasting. These secondary pollutants are very troublesome to clean up.

But now the laser to remove the rust on the metal surface, and there is no such concern at all. Because laser cleaning does not come into direct contact with the metal, no mechanical contact means no friction damage. Also, no blasting media means no waste is generated and no secondary cleaning is required.

Another important reason why

laser rust remover is widely used in the industrial field is that laser cleaning is more environmentally friendly. In the past, many users used chemicals to remove rust remaining on metal surfaces. This method can indeed remove contaminants from the metal surface, but these chemical components are very corrosive and may cause damage to the metal workpiece. There is also the discharge of a large amount of liquid pollutants after chemical cleaning, which may pollute the environment.

With the enhancement of people's environmental awareness and the stricter requirements of environmental protection laws, it is obvious that we can no longer take this kind of cleaning method that is harmful to the environment. Laser cleaning does not use any medium and does not produce pollutants that are harmful to the environment. It is a green and environmentally friendly industrial cleaning method.

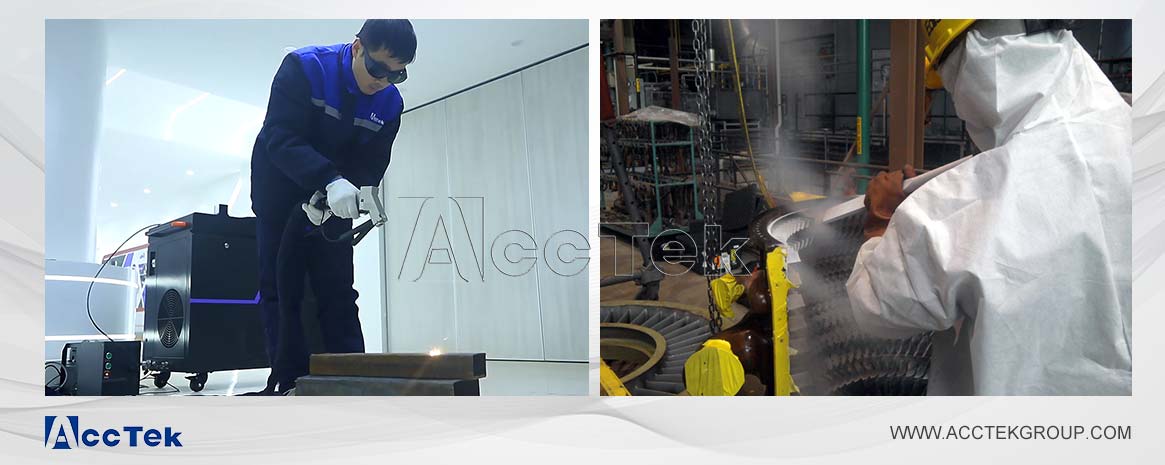

Another traditional rust removal method is to use dry ice for cleaning. Although removing rust in this way will not cause damage to the metal surface, the disadvantage is that the cost is very high. On the one hand, the price of dry ice itself is very expensive; on the other hand, the cost of transportation and storage of dry ice is also very high. If dry ice is used to derust construction steel plates or other large-area metal materials, the overall cost is very high. Moreover, the process of cleaning with dry ice will generate a large amount of CO2, so it is necessary to work in a well-ventilated environment, otherwise it will be life-threatening to the staff.

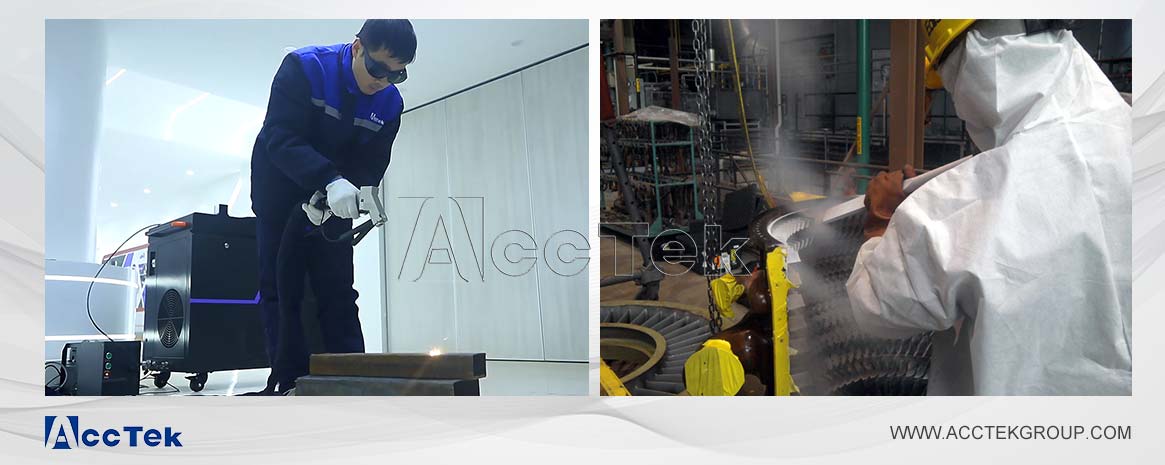

Using a laser cleaning machine to remove rust will not have these problems. Because the laser can be used when it is powered on, the laser cleaning machine does not require any other consumables except for a small amount of power consumption, so there will be no additional cost. And the portable laser cleaning machine is easy to move and has no requirements on the working environment. You can start using it anywhere you need to remove rust.

Laser rust removal VS Dry ice rust removal

Laser rust removal VS Dry ice rust removal

Why is the

portable laser cleaning machine accepted and recognized by everyone? Presumably through the above introduction, everyone should know the reason. It is because it is more environmentally friendly to remove rust in this way, it does not generate dust or liquid pollution, and it is also a more healthy and friendly operation method for the operator. In addition, the laser cleaning machine has a special host, which can be used to remove rust when the power is turned on. Not only is the cost lower, but it is also very convenient and simple to operate. Laser cleaning is a safe and reliable way to remove rust.