Laser cutting and plasma cutting are the two main ways of processing metal. In this article, we will introduce the differences between these two metal cutting methods from various aspects.

First, let's understand how laser cutting machine and plasma cutting machine work.

A plasma cutting machine is a machine that processes metal materials with the help of plasma cutting technology. Plasma cutting is a processing method that uses the heat of a high-temperature plasma arc to melt (and evaporate) the metal part or part of the incision of the workpiece, and uses the momentum of high-speed plasma to remove the molten metal to form an incision. What we call plasma is a gas heated to extremely high temperatures and highly ionized.

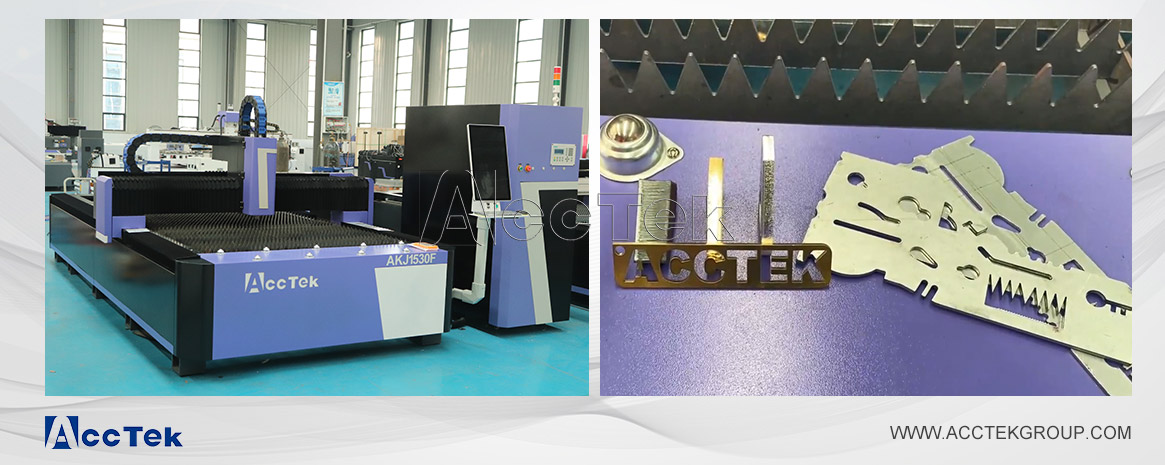

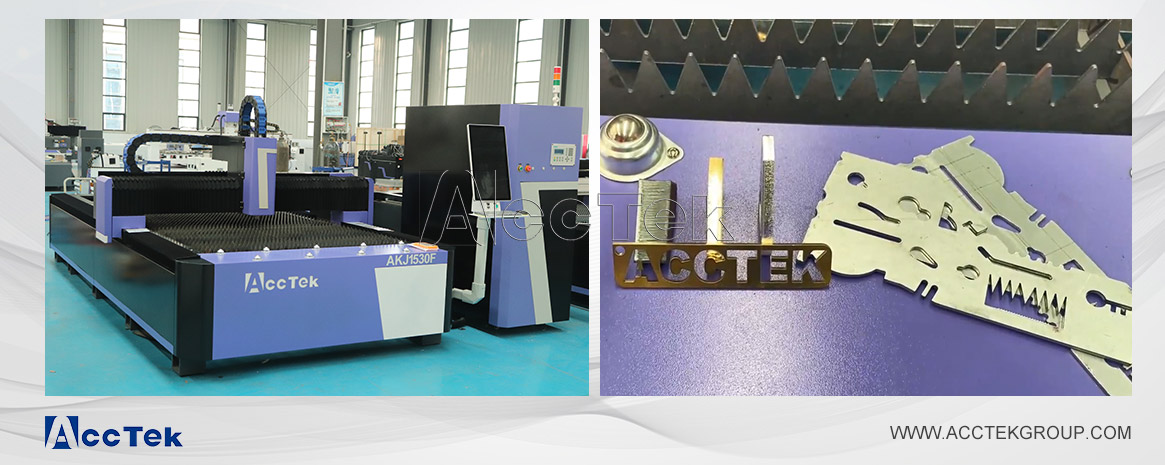

The laser cutting machine we are talking about here refers specifically to the fiber laser cutting machine, which is the CNC laser equipment professionally used in metal cutting. Laser cutting is to use a focused high-power density laser beam to irradiate the surface of a metal material, so that the irradiated material rapidly melts, vaporizes, ablates or reaches the ignition point, and at the same time, the molten material is blown out with the help of a high-speed airflow coaxial with the beam.

Advantages and Applications of Plasma Cutting Machines

The advantages of the plasma cutting machine are that the plasma arc energy is more concentrated, the temperature is higher, the cutting speed is faster, the deformation is small, and it can also cut stainless steel, aluminum and other materials. The disadvantage of plasma cutting is that the arc light is strong, the noise is large, and there is a lot of dust, which has certain pollution to the environment. When plasma cutting medium and thick sheet metal, many use underwater plasma cutting, and the cutting thickness is also limited. In addition, gas flow, arc length, current size, and cutting speed all affect the quality of metal cutting, and poor mastery will result in suboptimal workpiece cutting.

The working gas that can be used by the plasma cutting machine has a significant impact on the cutting characteristics of the plasma arc, as well as the cutting quality and speed. The working gas mentioned here is the conductive medium of the plasma arc, and it also excludes the molten metal in the cut. Commonly used plasma arc working gases are argon, hydrogen, nitrogen, oxygen, air, water vapor and some mixed gases.

The plasma cutting machine can cut various metals that are difficult to cut by oxygen cutting with different working gases, especially for non-ferrous metals (aluminum, copper, titanium, nickel), the cutting effect is better. Its main advantage is that when cutting metal plates with small thickness, the plasma cutting speed is fast, especially when cutting ordinary carbon steel sheets, the speed can reach 5~6 times that of oxygen cutting method, the cutting surface is smooth, the thermal deformation is small, and The cutting surface is smooth, the thermal deformation is small, and there is almost no heat affected zone.

Advantages and Applications of Fiber Laser Cutting Machine

Fiber laser cutting machine is an important application in the field of metal cutting. Its working principle determines that the wavelength emitted by the fiber laser cutting machine is more conducive to metal absorption, so it is conducive to speeding up the cutting speed. Moreover, the edge of the metal material after laser cutting is smooth and flat, and no other processing is required. The advantages of high efficiency and high precision have made fiber laser cutting machines popular with metal manufacturers since their inception, and gradually occupy a dominant position in the field of metal cutting.

Compared with plasma cutting machines, fiber laser cutting machines have obvious advantages in the cutting speed of thin plates. In addition, the laser cutting edge slope is low, and the surface quality after metal cutting is higher. Another advantage of fiber laser cutting metal is that it is very environmentally friendly, it does not generate harmful dust and arcing like plasma cutting, and is more in line with the requirements of increasingly strict environmental laws.

In recent years, with the decline in the cost of high-power lasers, the demand for fiber laser cutting machines has also shown rapid growth. On the one hand, the plasma cutting machine is prone to large deformation when cutting sheet metal below 6mm, which requires high cutting accuracy. On the other hand, laser cutting metal has obvious process advantages, especially for high melting point materials, heat-resistant alloys, super-hard alloys, semiconductor materials, non-metallic materials and composite materials. Although the initial investment of fiber laser cutting machine is much higher than that of plasma cutting machine, in the actual use process, whether it is the consumption cost of wearing parts or equipment operating cost, fiber laser cutting machine is far lower than plasma cutting machine.

At ACCTEK LASER, we can provide you with fiber laser cutting machines in the power range of 1000W-30000W to suit your plate cutting needs of different thicknesses. Higher power laser cutting machines not only mean that thicker sheet metal can be cut, but also higher cutting results. As for the specific use of plasma cutting machine or

laser cutting machine, it depends on your production purpose, cost budget and processing accuracy requirements. If you are still unable to choose, you can contact us and let our experts advise you.