With the development of the country’s industrialization, traditional woodworking has evolved from relying solely on manual axe, chisel, sawing and planing to now relying on CNC electric tools. Mechanization has not only greatly improved the production and processing efficiency of woodworking practitioners, but also improved the quality of products. Meet the quality requirements of end customers.

In the woodworking machinery manufacturing industry,

CNC engraving machines are generally divided into two categories, one is the CNC plane engraving machine, and the other is the three-dimensional engraving machine. In fact, there is also a laser engraving machine among

CNC engraving machines, which is generally not used in the wood processing industry, but this laser engraving machine also needs to be used in some woodworking industries. When the process is relatively fine, our furniture machinery manufacturing industry generally uses mechanical CNC engraving machine.

Although they are all machine-made

CNC engraving machines, why is there a big gap between CNC engraving machines on the market? Some four-axis CNC engraving machines only cost 20,000-30,000 yuan, that is, four-axis, and some prices are more than 20,000 yuan. In fact, a penny and a penny apply to any industry, but in our machinery manufacturing industry, we what can be noted is practicality.

It is very practical. There are two kinds of

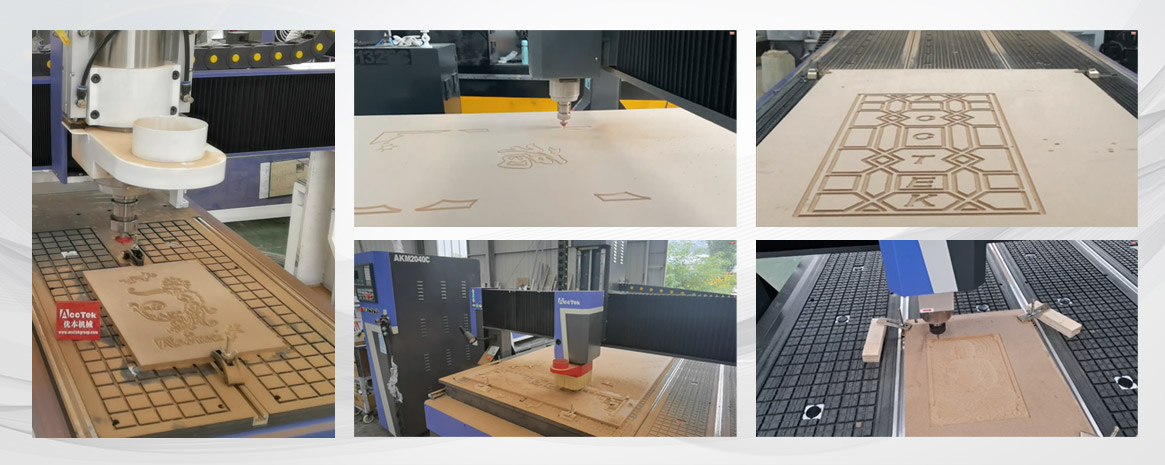

CNC engraving machines. One is a three-dimensional engraving machine, and the other is a flat engraving machine. CNC engraving machine can be used in panel furniture manufacturing, solid wood furniture manufacturing, new Chinese furniture and modern Chinese furniture.

The main part that affects the

CNC engraving machine is the configuration. The higher the configuration of the CNC engraving machine, the higher the corresponding price. Generally speaking, the price of 3D engraving machine is higher than that of flat engraving machine. The configuration of the three-dimensional engraving machine is usually on the high side.

Of course, this does not mean that twenty to thirty thousand CNC engraving machines are unavailable. Two to thirty thousand

CNC engraving machines are generally suitable for advertising manufacturing, and some small model and toy manufacturing industries are suitable for this CNC engraving. Strictly speaking, this can only be regarded as an engraving machine, not a CNC engraving machine. This simplest engraving machine uses leather belts to transmit the power of the motor and performs some simple engraving, milling and hollowing operations.

If you are a CNC machining service provider, it is very important to choose a high-quality CNC machine tool. You can learn about our CNC engraving equipment and metal cutting equipment online, and we will provide you with professional services and suggestions. Believe that our machines will provide you with high-quality workpieces and win more customers.