With the continuous advancement of science and technology, the products currently used are constantly being updated. Before processing these products, it is necessary to have a certain understanding of processing machines. The application of laser cutting machines makes many companies process new products. , It’s much more convenient, and the work efficiency has been improved a lot. For some friends who are familiar with laser cutting machines, 3D

laser cutting machines are not unfamiliar. Let’s introduce 3D laser cutting machines to let some newcomers understand Let's take a look at the characteristics and advantages of the 3D

laser cutting machine.

The 3D

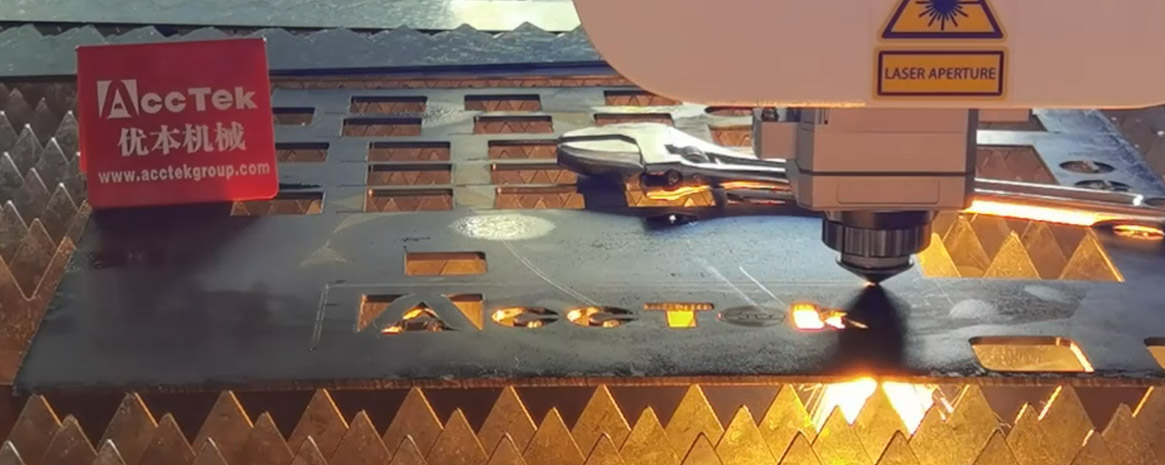

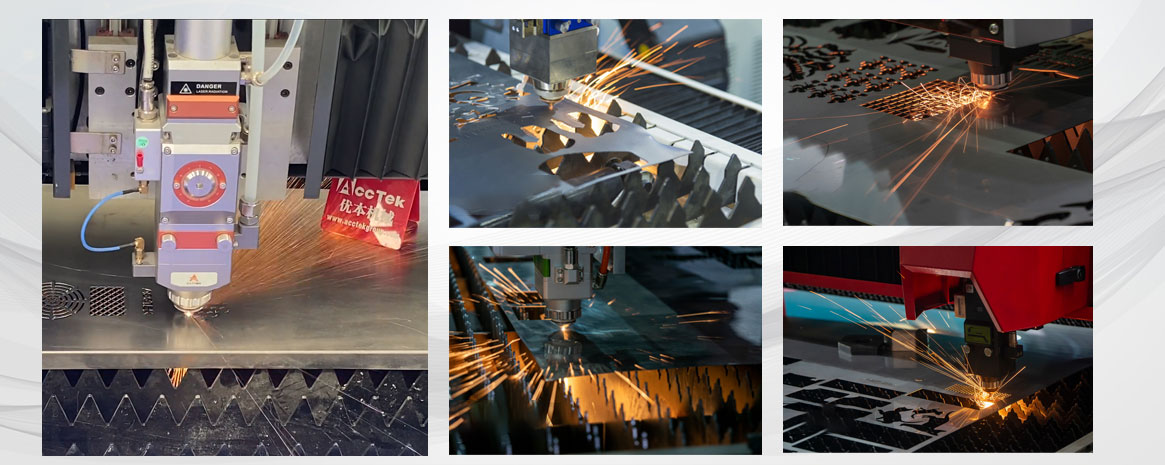

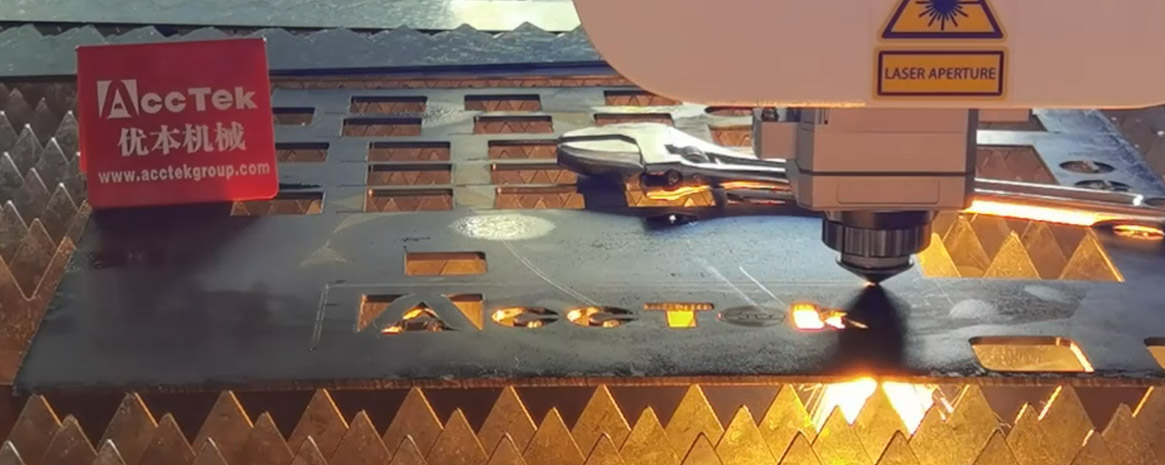

laser cutting machine can work on any surface without the need to manually adjust the angle. The laser cutting equipment is equipped with a dedicated laser cutting head, which can perform various processing on three-dimensional processing objects. Using robot automatic operation technology, equipped with professional high-precision excitation optical cutting head. The laser output power is stable, the processing format is large, and it can accurately cut metal materials of different thicknesses, such as sheet metal, stainless steel, carbon steel, etc.

Three-dimensional

laser cutting utilizes the flexible and fast motion performance of industrial robots. According to the size of the workpiece to be cut by the user, the robot can be installed in front or inverted, and teach programming or offline programming for different products and different trajectories. The sixth axis of the robot loads a fiber laser cutting head to cut three-dimensional irregular workpieces; the fiber laser cutting head is equipped with a follow-up device and an optical path transmission device. The optical fiber is used to transmit the laser to the cutting head, and then use a focusing system to focus. A number of focusing systems have been developed for plates of different thicknesses to perform multi-directional cutting of various three-dimensional metal plates to meet customer needs.

Three-dimensional

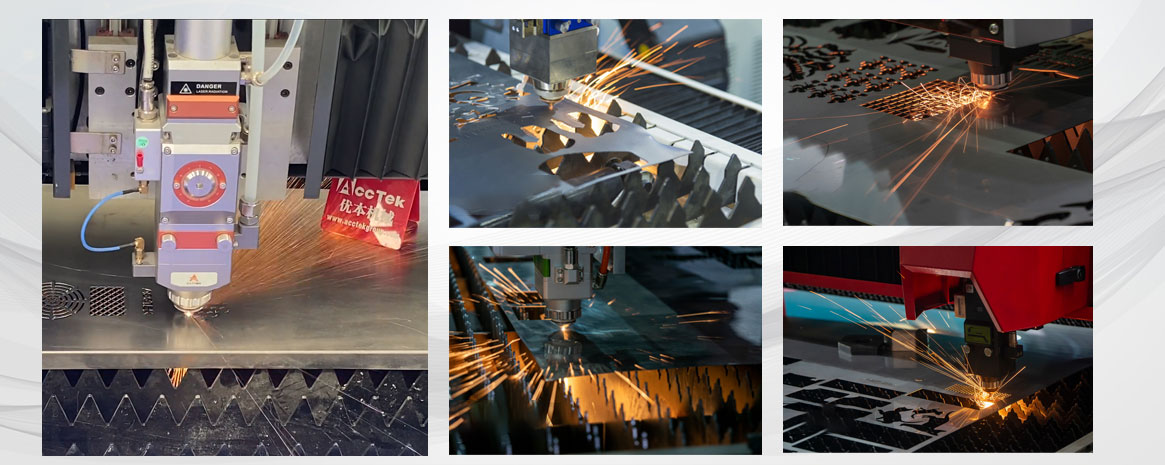

laser cutting machines are widely used in various manufacturing industries such as automobiles and ships, machinery manufacturing, elevator manufacturing, advertising production, home appliance manufacturing, medical equipment, hardware decoration, fitness equipment, metal processing services, etc., especially in auto parts processing On the other hand, it has advantages that other cutting machines cannot match, such as body design and manufacturing, which greatly reduces the investment risk of mold development. It is mainly used for the development of new models, online cutting and deformed vehicle production, such as cutting prototype parts and cutting body panel holes And trimming, cutting steering wheel holes, body windshield, roof support holes, airbag parts, hydroforming parts, etc.

Three-dimensional

laser cutting can realize dynamic two-dimensional and three-dimensional cutting. The machine structure is designed according to ergonomics. Even the most complex curved surface can be processed with simple operations. High precision, which can meet the manufacturing precision of aluminum alloy EMUs, stainless steel subways and other products. It has high economic efficiency and can replace the traditional manufacturing process. The trimming die and punching die have simple process steps, short manufacturing cycle, fast cutting speed, small cut width, high processing quality, which can greatly reduce costs and shorten the development cycle of new models. It has good economic value and application prospects.