Broadly speaking, the

engraving machine can be divided into advertising engraving machine, woodworking engraving machine, and stone carving machine, advertising engraving machine can be understood as a low-end woodworking engraving machine, just longmen height is 15 cm, woodworking engraving machine is widely used in home decoration industry to do partition, setting wall, beautiful case, waist line, wall hanging, and screen, carve patterns or designs on woodwork wood for making furniture in the furniture industry and the production of archaize furniture, the wooden door industry mainly carving the matsuzaka, oak, log and density board making wooden door, door, cabinet door, etc, in the wedding industry is mainly used for making wedding props and frame cut, mainly produced classical instruments in musical instrument industry, in addition to this,It can also be used in industry to cut special boards.Stone carving machine is able to natural stone, glass, ceramics on calligraphy and painting carving high-tech automatic computer control carving equipment.

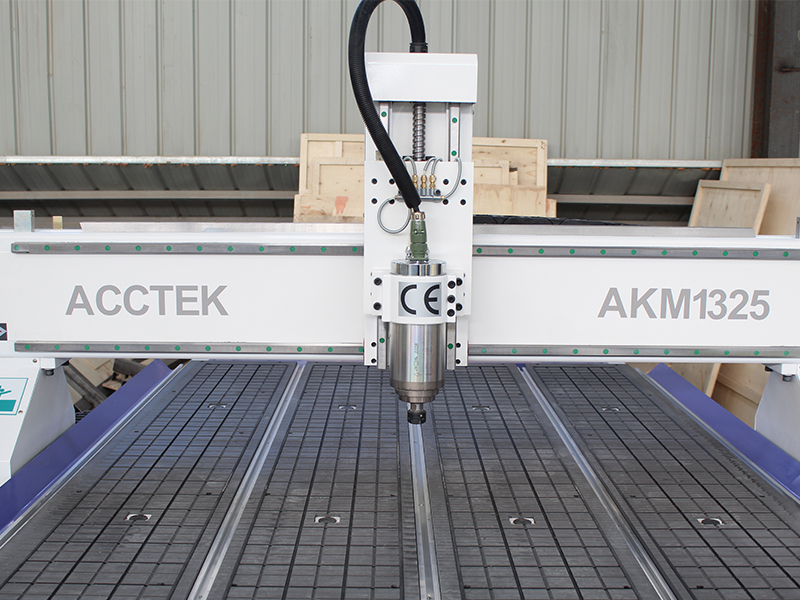

CNC engraving machine is more and more widely used, then engraving machine and what is different from other CNC equipment advantages?

1. Combination of artistic surface modeling method and geometric surface modeling method

With expanding of the CNC engraving application, engraving is no longer just make the finishing point, has gradually infiltrated in the field of product design and product processing, such requirements carved design tools must have certain surface modeling function, more because of sculpture is a kind of unique design method, need more than one form of the products is not expressed in accurate digital function, depending on the designer's feeling, only art surface mixed model and geometric surface can guarantee engraving in industry can have a more brilliant performance.

2. Use high precision and high speed spindle motor

Using precision high-speed spindle motor is the basic guarantee for the small tools high-speed engraving and high-speed precision spindle motor of high speed and high precision, low noise, low vibration, high speed constant power etc, to ensure that small cutting tool to obtain the rotation of the cutting speed, high accuracy, generate enough high-speed, less vibration and the cutting force and cutting knife.

CNC engraving machine suitable for which industries processing?

Engraving processing has been involved in all walks of life, distribution is also special wide, there are gifts, advertising, seal industry, wood processing industry, construction industry, art model industry, machining and tooling mold!To processing of the material is special, also including metal, stone, PVC board, ABS board, acrylic, imitation stone, rubber, double color boards, aluminous model board and so on various materials as people to the carved machine understanding and mastering gradually deepened, application scope will be expanding and application level will also gradually increase, carving processing is certainly there will be more broad prospects.

1, can pause at any time, increase or decrease the speed, adjust the depth, and can preview the engraving path plane and three-dimensional map stepless speed regulation is convenient for carving different materials, suitable for different industries.

2. Convenient cutter breaking, arbitrary dot engraving, no need to re-typesetting or re-engraving back to the origin, easy to operate, easy to master, support typesetting software such as TYPE3, TYPE3, fine carving, compatible with multiple CAD/CAM software such as TYPE3 / Artcam JDPaint/ Proe/G

3. The fuselage has high bearing capacity and no deformation. The imported double-nut screw ensures the carving speed, and the high-precision square linear guide rail can effectively improve the carving accuracy.

4, using high speed water-cooled frequency conversion motor, with strong cutting, high frequency and long life, and other characteristics, can work for a long time continuously.

5. Optimized design of the machine, linear guide rail (cylindrical or square) is adopted for long service life.

6, with power cut and timely correct error code file function, the origin of automatic error correction function.

1. Mechanical maintenance

1) Vacuum the dust and dirt in the machine once a week. All electrical cabinets should be closed to prevent dust.

2) Each guide rail should be cleaned regularly to remove dust and other sundries, to ensure the normal equipment rack should be wiped frequently, add lubricating oil, to ensure lubrication and no sundries.

3) Check the steel belt frequently and make sure it is tensioned.

4) Check the straightness of the track and the perpendicularity of the machine every six months, and timely maintain and debug abnormal results.

2. Repair and maintenance of gas road

1) Gas circuit system maintenance.Check the air system frequently and deal with the air leakage and parts that can't be used normally in time to ensure the air flow.Dust and sundries should be cleaned frequently to prevent premature aging of gas passing by.

2) Maintenance of the pressure reducing valve adjust the pressure reducer, adjust the pressure gauge to the required pressure, during the adjustment process should make the pressure from small to large, ensure that the pressure reducer can be continuously adjusted.If continuous regulation is not possible or gas leaks from the relief valve a new pressure relief valve must be replaced.If the parts of the gas pressure reducer are folded by itself, the equipment will be damaged, even serious personal injury.

3) Maintenance of the backfire preventer on the cutting torch cutting mouth.The cutting torch adopts the machine cutting torch produced by professional manufacturers. If the cutting torch is used for a long time, the sealing surface is damaged and the sealing with the cutting mouth is not strict. It must be repaired with special tools.Cutting torch also adopts the standard fast cutting nozzle produced by professional manufacturers, for the new cutting nozzle, must be checked qualified before use.The cutting nozzle is contaminated and special tools are needed to clean the preheating flame hole and cut the oxygen channel.

4) Tempering preventer is an important part to ensure safety. According to the requirements of the safety department, tempering preventer is strictly prohibited to disassemble without permission.Therefore, after the use of tempering preventer gas resistance to ensure that the gas flow requirements or leakage, be sure to ask professional replacement.Equipment operators must pass professional training before they can take up their posts.Non-professional personnel are strictly prohibited to operate the machine.