CNC router machine is CNC machinery and equipment used to process materials such as wood, plastic and soft metals, most of them adopt gantry type structure, which can be adjusted to meet the maximum limit of feeding material. The heavy-duty bed of steel structure ensures the overall stability of the machine. The guide rail adopts square guide rail with stable support surface. Rack and pinion transmission, smooth transmission, to ensure long time high speed operation without deformation, no shaking.

Types of CNC Wood Router Machine:

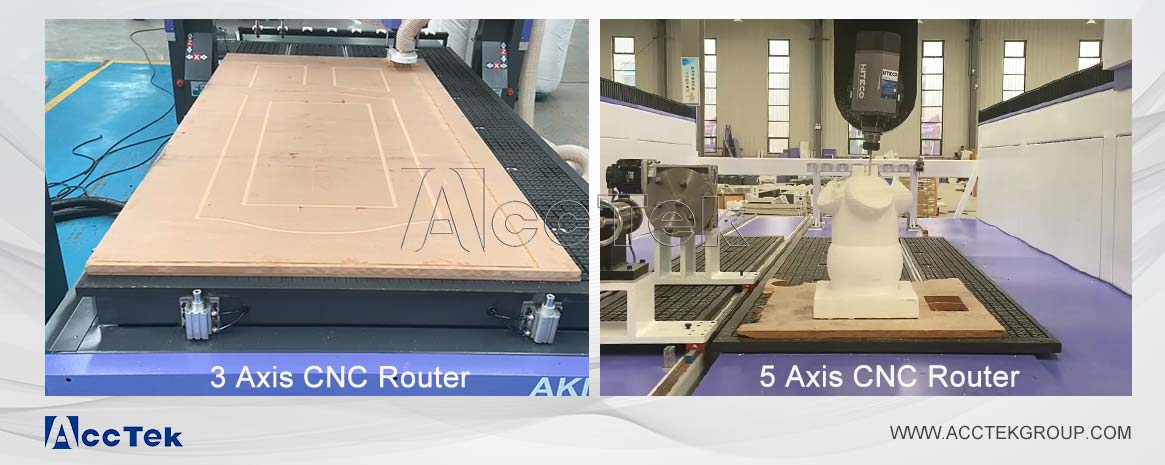

CNC wood router machine based on the operating principle is divided into 3 axis cnc router machine, 4 axis cnc router and 5 axis cnc router machine.

These three types of cnc wood router can be carved out of three-dimensional relief role, but the detailed analysis of the different great. 3 Axis cnc router woodworking machine is also known as a flat cnc cutting and engraving machine, it carved out of the goods can only be flat. 4 Axis cnc router woodworking machine is also called four-axis cylindrical cnc cutting and engraving machine, carving out the goods is considered the real three-dimensional goods. 5 Axis cnc router woodworking machine is more powerful, can carve a wider range of goods.

Introduction of 3 axis, 4axis and 5 axis cnc cutting and engraving machine:

According to different work requirements, you can choose 3 axis, 4 axis or 5 axis woodworking engraving machine for processing, the following is the introduction of the 3 types of machines, which can be used as some basis for choosing the machine:

3 Axis cnc router is the coordinate axis of the three axes, namely x-axis, y-axis, z-axis, where x indicates the left and right space, y indicates the front and back space, z indicates the upper and lower space, so that the formation of the human visual three-dimensional sense, 3 axis cnc router engraving machine is made by 3 axis carving software can be applied to a variety of flat materials for cutting, 2D carving, 3D carving.

4 Axis cnc router machine has all the same axes of a 3-axis router plus the additional A-axis that rotates the spindle around the X-axis up to 180 degrees during the cutting process. This rotational axis allows cuts to be executed on multiple sides of the workpiece without resetting, 4-axis CNC routers are the preferred method for advanced, intricate cuts and carvings like those often seen in furniture, musical instruments, cabinetry, and more.

5 Axis cnc router machine also shares the same three core axes (X, Y, and Z), but has two additional rotational axes – the C axis that rotates around the X-axis and the B-axis that rotates around the Y-axis. This dual-rotary feature allows for cutting along five edges of material at the same time. As such, 5-axis CNC routers are often used to cut large, three-dimensional parts in the auto, aerospace, and watercraft industries, ect.

Main Features of our AKM1325 cnc router wood cutting machine:

Among the many types of CNC wood router machines, AKM1325 is a very popular machine, it is rich in functions and cheap, here are its main features.

1. High temperature tempering treatment, welded steel tube T type machine bed and gantry, high rigidity, bearing strength better.

2. Y axis with double Leadshine stepper motor and driver, moving stably.

3. Linear square guide rail with automatic oil lubrication device, ensuring long life time working, reduce the time of machine maintenance.

4. China air or water cooling spindle, more powerful, low noise, not easy to break cutters, suitable for engraving and cutting work .

5. Square guide rail transmission for X Y-axis, ball screw transmission for Z-axis, ensuring the machine fast speed and higher precision.

6. Good software compatibility, with machine, we provider Artcam, Aspire, Powermill etc.

7. Professional factory with Mach 3 control system, can provider good after sales service and technology support .

8. Vacuum table using high-density material with great suction strength, comfortably all sizes of work piece.

9. With rack and gear transmission, it can have faster speed than ball screw machines.

If you want faster cutting speed and higher engraving precision when processing woodworking projects, you can also choose

ATC CNC router, CNC machine tools with auto tool changer are more suitable for mass production.

To choose a most suitable cnc router, you can contact us and send your requirements to us, then we can help you to choose your machine.