Some manufacturers often consider whether to choose a

laser cutting machine or a

CNC machine tool when they first choose processing equipment. Then let's take a look at the difference between laser cutting machine equipment and CNC machine tools today?

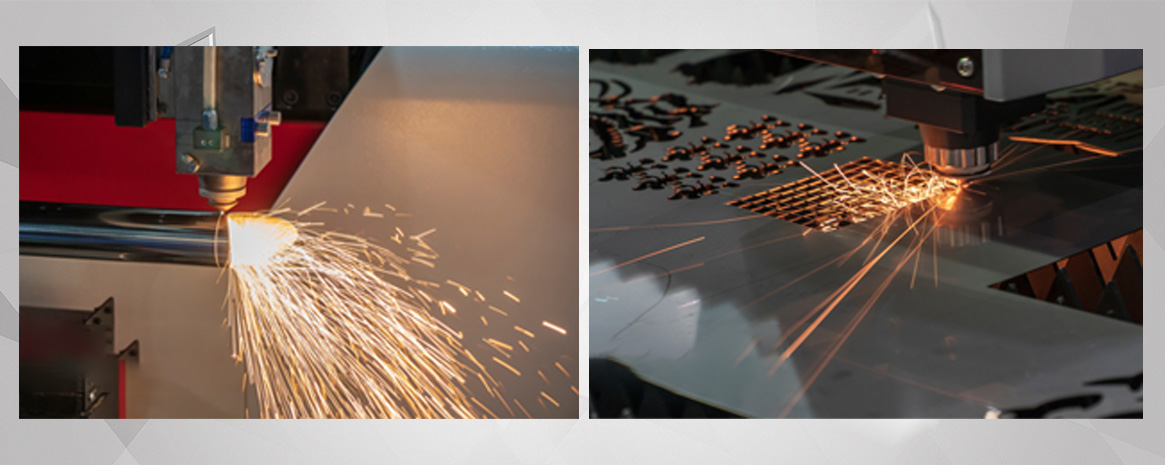

Laser cutting technology is currently receiving widespread attention in the metal industry. Many manufacturers have bid farewell to CNC machine tools and choose laser cutting machines. The working principle of laser cutting machines is to irradiate the surface of the material with a high-energy beam generated by the laser to irradiate the metal material. Rapid melting, to make the material appear linear melting by moving the beam to achieve the purpose of cutting

CNC machine is a kind of cutting equipment controlled by computer. Compared with traditional sawing equipment, CNC machine tools have greatly improved the cutting accuracy and have many advantages compared with cutting cost. However, the CNC punching machine needs a mold to cut when cutting. This is the advantage of the

laser cutting machine. It does not need a mold and can be cut by importing drawings.

Advantages of laser cutting

Laser cutting machines have been widely promoted in various industries. The main reason is that they have many advantages and benefits in the work process. Compared with traditional cutting machines, they are better. In particular, the following important advantages can be used to break traditional cutting. The limitations of the machine.

Higher performance and safety

Compared with the traditional cutting machine, the laser cutting machine has stronger performance, exerts stronger safety in the work, and has the continuous fast and efficient working mode. No special maintenance is required, and a large amount of usage costs can be controlled, providing strong power for continuous production during work, promoting work efficiency, and ensuring better work quality.

Higher cutting accuracy during work

By using a

laser cutting machine for cutting work, it is more accurate than traditional cutting machines and has a finer processing effect, avoiding poor cutting accuracy, thereby saving production and processing costs. Improve production efficiency, promote production accuracy, and achieve high-quality cutting effects, and the overall effect of product production will be better.

Advantages of CNC machine tools

Highly flexible

Machining parts on a CNC machine tool mainly depends on the processing program. It is different from an ordinary machine tool. There is no need to manufacture and replace many tools and fixtures, and there is no need to frequently adjust the machine tool. Therefore, CNC machine tools are suitable for occasions where parts are frequently replaced. That is, it is suitable for single-piece, small-batch production and the development of new products, shortens the production preparation cycle, and saves a lot of process equipment costs.

High processing accuracy

The machining accuracy of CNC machine tools can generally reach 0.005~0.1mm. CNC machine tools are controlled in the form of digital signals, and the average error of the backlash and lead screw pitch of the machine tool feed transmission chain can be compensated by the CNC device, so the CNC machine tool positioning The accuracy is relatively high.

The processing quality is stable and reliable

To process the same batch of parts, on the same machine tool, under the same processing conditions, using the same tool and processing procedure, the cutting path of the tool is exactly the same, the parts have good consistency, and the quality is stable.

High productivity

The CNC machine tool can effectively reduce the processing time and auxiliary time of the parts. The spindle speed and feed of the CNC machine tool have a large range, allowing the machine tool to carry out a large range of processing area.

The above are some introductions to

laser cutting machines and CNC machine tools. If you want to know more about laser cutting machines or CNC engraving machines, please consult our official website for details. We have professional technicians to solve your questions. .