With the improvement of modern industrial equipment production technology, fiber lasers have entered the application market. With the advantages of high processing efficiency, good beam quality, and low operation and maintenance costs, they quickly occupy the market. After years of development, the

fiber laser cutting machine has gradually matured, and new technologies have been continuously derived, and the application power has been continuously improved. With the emergence of high laser powers such as 10KW, 12KW, and 20KW, the 10,000-watt laser cutting machine technology has become the main competitive field in the market.

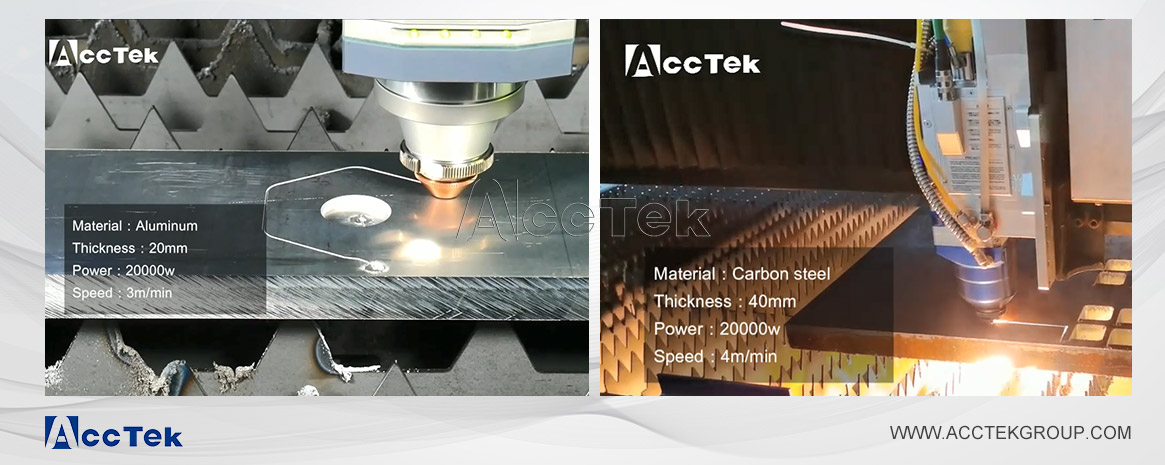

As the power of laser cutting machines gradually increasing, laser cutting is also developing from light and thin plate cutting to heavy industrial thick plate cutting. The thickness of carbon steel sheets that can be cut by ultra high power 30KW laser cutting machine reaches 120mm. In the process of continuous improvement of cutting technology, my country has been trying, and 20KW laser cutter have been gradually applied to cutting 90mm carbon steel sheets. In addition, the size range of workpieces used in laser cutting technology is increasing.

In terms of cutting speed, the speed of each grade of laser cutting machine is quite different. When cutting sheet metal of the same thickness, the speed of 12kW laser cutting machine is about 21% higher than that of 10kW laser cutting machine. In terms of cutting thickness, the current 10,000-watt laser cutting machine can cut stainless steel with a thickness of 50mm. Although the 10,000-watt laser cutting machine is more expensive, the production efficiency is also high. Therefore, labor cost can be saved.

High-power fiber laser cutting machine has extremely low operating costs, easy maintenance of optical paths, and ergonomic design. High-power equipment is an inevitable trend in the development of laser cutting technology.

The following introduces the three major characteristics of high-power fiber laser cutting machine:

1. The signal transmission takes the form of electricity-optical-electricity, the light-emitting part and the light-receiving part are not in contact, which can avoid the feedback and interference that the output end may produce to the input end;

2. Strong ability to suppress noise interference;

3. It has the advantages of durability, high reliability and fast speed. The response time is generally within a few, and the response time of high-speed optocouplers is even less than 0.01μf.

Therefore, when designing the system circuit of the ultra-high power fiber laser cutting machine, attention should be paid to the isolation of the input signal circuit and the single-chip microcomputer. Here, optoelectronic coupling is the most commonly used method.

In the sheet metal processing industry, the fiber laser cutting machine is such a cutting tool, especially after the emergence of the 10,000-watt fiber laser cutting machine, the processing range and thickness of the laser cutting machine continue to break new highs, so the 10,000-watt fiber laser cutting machine what are the advantages of the machine?

1. Production efficiency

When the

10,000-watt laser cutting machine performs metal processing, the maximum laser cutting speed can reach 120m/s, which is unmatched by traditional processing methods. In view of the process requirements of blanking parts in the sheet metal processing industry, combined with the own characteristics of cutting equipment, cutting technologies such as flame, plasma and laser are widely used in sheet metal manufacturing enterprises. With the rapid development of cutting technology and the continuous improvement of the overall performance of cutting equipment, the status quo of laser cutting, plasma cutting as the main, and flame cutting as the supplement has gradually formed.

When processing metal, the cutting speed of the high-energy laser 10,000-watt laser cutting machine can reach a maximum cutting speed of 100 meters per second, which is unmatched by the traditional metal cutting efficiency. High-speed machining not only saves machining time, but also saves labor costs.

More importantly, traditional industrial processing will perform a series of complex operations such as measuring and drawing lines on the workpiece before cutting the workpiece, and it is a waste of time. The laser cutting machine saves this step and only needs to cut the pattern The finished product can be processed quickly after input, which can effectively improve the production efficiency.

High-speed machining saves both labor costs and production time. What is important is that the traditional processing method requires a series of complex operations such as measuring and scribing the workpiece before cutting the workpiece. A waste of time, the laser cutting machine saves this step, and only needs to enter the drawn pattern to quickly process the finished product, which effectively improves the production efficiency.

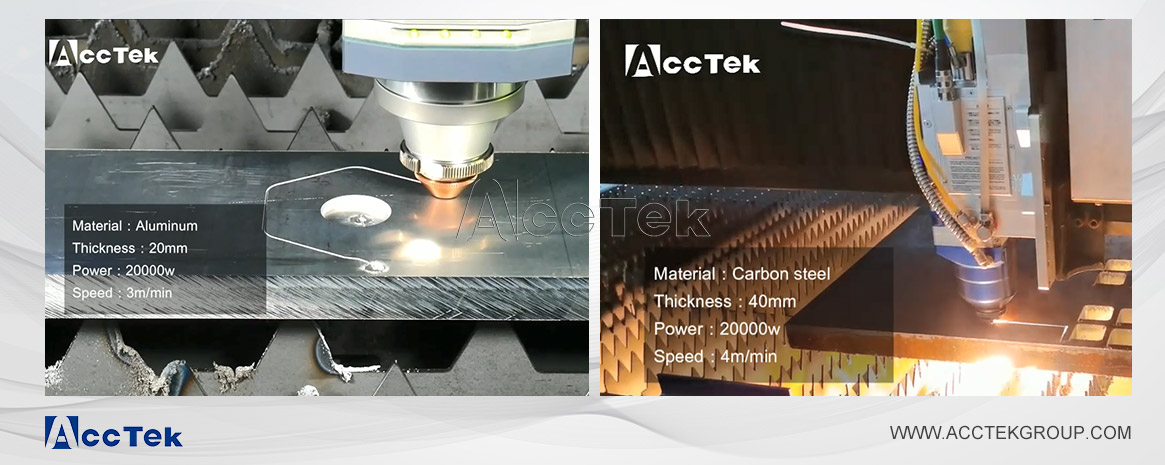

2. Sheet thickness

At present, laser cutting machines can be fully applied in the field of metal processing. Whether it is common metal materials such as stainless steel and carbon steel, or difficult-to-manufacture high-reflection materials such as aluminum plates, fiber laser cutting machines can be easily dealt with without pressure. With the continuous improvement of the power of laser cutting machines, the thickness of the sheet metal that can be processed is also increasing.

At present, the beam pattern of high-power lasers has been improved, and the related application of microcomputers makes it possible to produce high-precision, high-speed processing and cutting equipment. At present, the speed of laser cutting technology applied in my country has exceeded 25m/min, the moving speed of the two axes of the cutting machine can reach 240m/min, and the acceleration during operation can reach about 10G. On a 1mm thick board, about 500 holes can be cut per minute for about 10mm holes.

The 10,000-watt laser cutting machine is an inevitable trend in the development of the laser cutting industry. On the one hand, due to the high competition pressure in the laser cutting equipment market, the kilowatt-level product market is saturated, and the competition is particularly fierce; on the other hand, the higher the power of the laser cutting machine, the higher the processing efficiency, the better the processing capacity, and the lower the cost, which is in line with the trend of modern market development. It is believed that in the development process after the

laser cutting machine, the laser power will continue to increase.