This is a comprehensive article explaining CNC routers, covering what a CNC router is, what a CNC router can do for me, what CNC router kits are, and the CNC router types and prices. By reading this article, you can better choose the right CNC router machine for yourself.

What is a CNC Router

CNC stands for Computer Numerical Control. CNC machining is a process used in the manufacturing sector that involves the use of computers to control machine tools. Tools that can be controlled in this way include lathes, mills, and grinders. A CNC router is one of many devices with CNC variants. Same as the hand-held router, the CNC router machine is used to cut different hard materials such as wood, acrylic, aluminum, plastic, stone, etc.

Why do we need CNC Router Machine

CNC router machine can perform different tasks like milling, drilling, sawing, planing, engraving etc. in wood workshop machines. Doing the same amount of work with simple hand or power tools consumes a lot of time and labor costs, and the whole process is laborious and tedious.

CNC router is controlled by computer numerical control, which can provide stable and excellent work and increase workshop productivity. Its advantages include automation, precision, repeatability, and reduced waste and errors. The repeatability feature allows you to make 100 identical parts and each part is guaranteed to be exactly the same as the first.

CNC Router Machine kits/components

Control System

The CNC router controller and computer system work together as the "brains" of these machines, telling the motors and drive systems which route and distance to move. The commonly used control systems of woodworking CNC routers include handle control and computer control.

The handle control does not need to be connected to a computer, the operation is simple, and it is easier to learn and master. The computer control method can preview the processing effect, and you can see the processing track at any time. Each function is displayed on the control panel, which is very convenient to operate.

CNC Router Spindle

Spindle is machine parts used for machining, and can be used for high-speed engraving, drilling and milling, drilling, cutting, etc. According to the cooling method, it is divided into air-cooled spindle and water-cooled spindle. When using a water-cooled spindle, it is necessary to pay attention to replacing the cooling water in time to ensure that the water temperature cannot be too high. The water-cooled spindle has the advantages of good cooling effect and low noise. Air-cooled spindles are suitable for users with water shortages, and are of course ideal for users in low temperature areas.

CNC Router Table

The worktable is divided into a T-slot table and a vacuum table. The aluminum T-slot workbench adopts the fixture fixing material, which has the characteristics of low cost and flexible method, and is suitable for hollow plates or small-sized workpieces. The vacuum table adopts the vacuum adsorption method, which has the advantages of high efficiency and fast speed, and is suitable for irregular plates or large-area plates. Of course, you can also choose T-slot and vacuum combination table to meet more processing needs.

CNC Drive System

Each axis uses a linear drive system. The CNC linear drive system consists of a motor, a direct bearing system and a lead screw. There are two kinds of motors on the woodworking CNC router, which are stepper motors and servo motors.

Stepper motors are a less expensive option with excellent performance and consistent quality, but are generally not closed loop systems. Servo motors provide a closed loop system, which means that after taking the bearings from the CNC controller, they send a signal back to the controller to check that they are doing their intended task.

Which CNC router is right for my job? How Much does a CNC router cost?

Knowing the type of CNC router machine makes it easier for you to choose the right CNC machine. Let's take a look at the most common types of CNC routers by function, axis, material, and application.

1. CNC Router for hobbyist and beginner woodworking

Link:

Small Woodworking CNC Machines product list

If you are just getting into the woodworking CNC industry, you can buy a cheap desktop CNC router engraving machine. ACCTEK has three types to choose from, namely AKM6090, AKM6012 and AKG1212. The size of these three CNC machine tools is 600×900mm, 600×1200mm, 1200×1200mm, and the machines of this size are suitable for processing advertising signs, handicrafts, children’s toys, models and other small wood products.

These CNC router machines meet your engraving and cutting needs at a very cheap price, around $2500-3500.

2. The best Woodworking CNC Router for businesses

Link:

3-Axis Woodworking CNC Router Machine product list

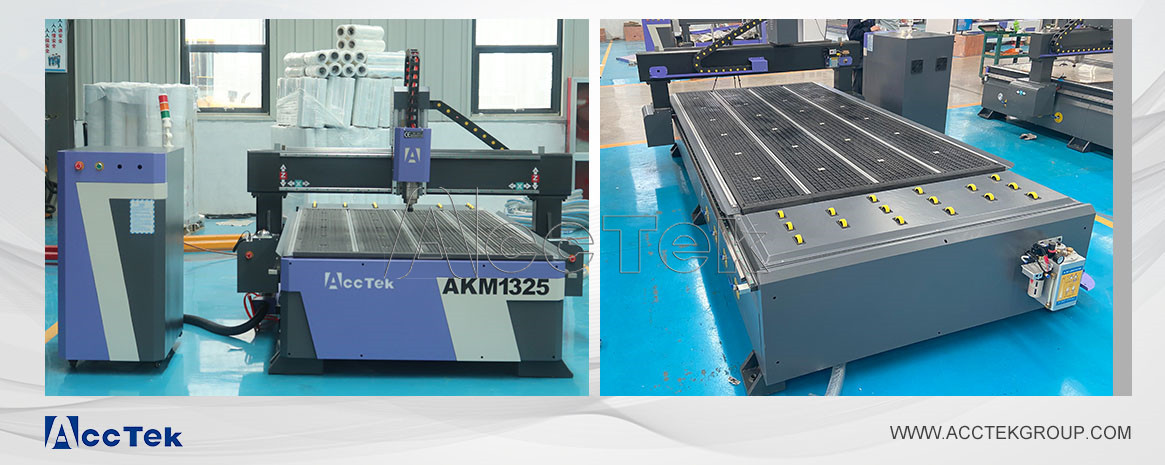

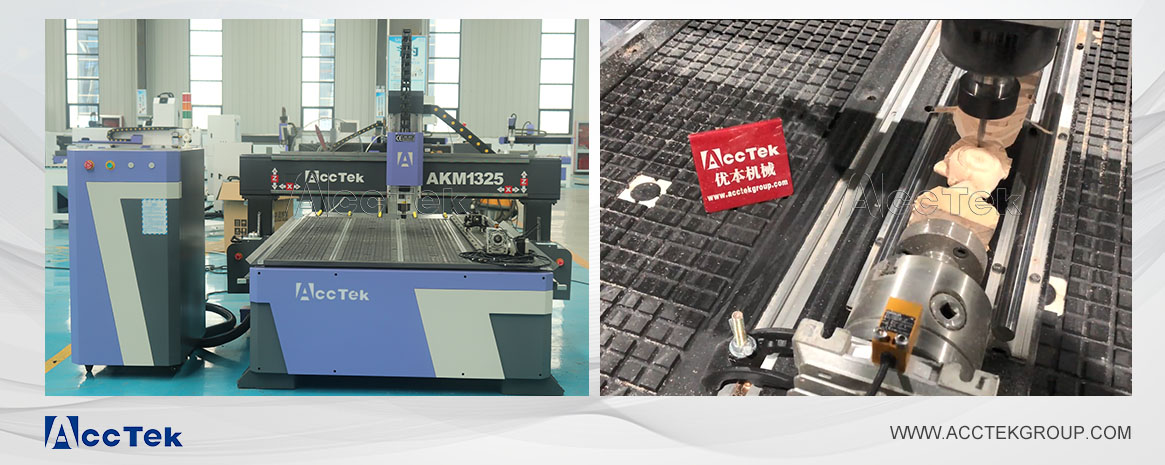

If you are a furniture maker, then it is recommended that you buy a large woodworking CNC router machine. AKM1325 (4×8ft) or AKM1530 (5×10ft) models can meet your needs. They can engrave, cut, drill, and mill wood. The rear of the machine tool is equipped with a feeding auxiliary wheel, which is convenient for feeding when processing large-sized plates and reduces the labor intensity of the staff.

This standard CNC wood router can run for a long time, produce high-quality products, and cost only about 4500-6500 US dollars, which is a good choice for small woodworking enterprises.

3. Industrial ATC CNC Router Machine

Link:

Automatic CNC Router product list

If your business focuses on mass production of woodworking projects, then choosing an ATC CNC router will better improve the efficiency of the workshop. The AKM1325C ATC CNC router has an automatic tool changer, which is loaded with 8 different tools. It can be controlled by a computer program to automatically change the required tools without stopping during the machining process. Therefore, different processing requirements such as cutting, hollowing, grooving, punching, etc. can be completed at one time, which greatly improves the processing quality and production efficiency.

And each ATC CNC router machine of ACCTEK factory is equipped with a double-bag dust collector, which can suck the sawdust waste into the dust bag during the process of cutting wood by the machine, reducing environmental pollution. Of course, the ATC CNC router price is also more expensive, and the cost is about 10,000-20,000 US dollars. But for larger businesses, it can pay for your machine faster and create greater benefits.

4. 4 Axis CNC Router

Link:

CNC Router 4 Axis Product List

The 4-axis CNC router can make all four axes of X, Y, Z and A work simultaneously. Accordingly, it is capable of sculpting various 3D items of regular, irregular, symmetrical and asymmetrical. A true 4-axis CNC engraving machine gives you more flexibility, it can engrave or mill cylindrical blanks at any angle from 0 degrees to 180 degrees.

The 4-axis CNC woodworking engraving machine can realize the processing of three-dimensional workpieces such as Buddha statues, Roman columns, and models. If you have the processing needs of 3D workpieces, complex workpieces, and special-shaped workpieces, this 4-axis CNC router machine can meet your diverse processing needs.

5. Rotary Axis CNC Router

The rotary axis CNC router machine is based on the ordinary 3-axis engraving machine, and adds a fourth axis, that is, the rotary axis. The fourth axis is a machine tool accessory that holds the workpiece on the chuck or between the two centers to rotate and position it. Due to the rotational motion of the fourth rotation axis, the CNC engraving machine can realize 3D machining of cylindrical surfaces and arc surfaces. In terms of use, it can machine planes, reliefs and cylinders.

The rotary axis CNC router machine has certain limitations when processing 3D projects. It can only do some regular, symmetrical cylindrical carving projects. Suitable for processing table legs, chair legs, Roman columns and other products.

What can you do with a CNC Router

Furniture industry

The furniture industry is one of the most widely used fields of woodworking CNC router machines. The CNC router can perfectly combine furniture design and furniture manufacturing by carving, cutting and hollowing out patterns on wooden boards, making it possible to customize furniture. The common wooden doors, cabinets, wardrobes, coffee tables, dining tables, sofas, screens, etc. in our lives are inseparable from the presence of woodworking CNC engraving machines.

Advertising industry

The application of CNC router machine in the advertising industry is mainly reflected in the engraving and cutting of two-color board, acrylic, PVC board, wood, MDF and other materials. CNC cutting machine can be used to make badges, crystal words, seals, trophies, handicrafts, signs, advertising words, advertising light boxes, etc.

Mold industry

The CNC router machine in the mold industry mainly embodies the carving of various wood and foam, such as ship model, car model, airplane model, etc. In addition, the metal CNC router can also be used for mold manufacturing of hardware, watches, glasses accessories, etc.

Stone carving industry

The stone CNC router machine replaces manual engraving, which greatly reduces labor costs and improves production efficiency. It can realize various processes such as lettering, hollowing out, carving, embossing and so on. The materials that can be processed are marble, granite, bluestone steles, etc.

As with other CNC machines, CNC routers stand out for their precise and efficient machining. In any case, CNC engraving machines are widely recognized for use in the field of manufacturing.

Are you looking for a CNC router to improve workshop production? Online communication, you can get more help.