With the continuous development of the industry, the demand for metal tubes is increasing.

Fiber laser tube cutting machines have become the first choice for the tube processing industry, and the tube processing technology has gradually matured. With the application of fiber laser tube cutting machine, the quality and efficiency of tube processing have made a qualitative leap.

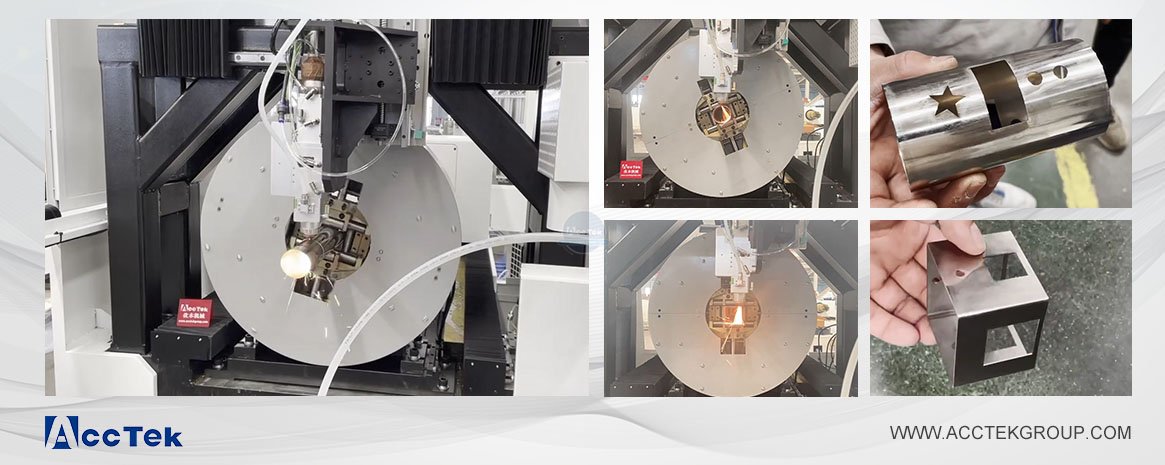

The fiber laser cutting machine can cut any pattern on the metal tube, and the laser can cut in any direction and angle, which provides favorable technical support for personalized processing. And the CNC laser machine does not need to open the mold for the first time, which greatly reduces the cost of the first mold opening of the traditional equipment and improves the processing efficiency.

Compared with traditional processing equipment such as flame cutting, plasma cutting and water cutting, the precision of laser cutting metal materials is much higher. At the same time, different materials may undergo slight expansion and contraction deformation during the processing process, and the fiber laser tube cutting machine can flexibly adjust according to these deformations, which is also impossible for many traditional processes.

Professional

tube fiber laser cutting machine AKJ60F can be used to cut square tubes, round tubes, rectangular tubes, oval tubes, hexagonal tubes and various heterosexual tubes. The maximum cutting diameter of the square tube is 150mm, the maximum cutting diameter of the round tube is 220mm, and the length of the tube that can be cut is up to 6000mm. The machine tool is annealed to eliminate internal stress and then finish machining, which can better solve the stress caused by welding and processing, thereby improving the rigidity and stability of the equipment. Better stability and longer service life.

The laser metal tube cutting machine AKJ60F adopts the design of electric clamps on both sides, which can automatically adjust the clamping force according to the pipe specification to ensure that the thin tube is not damaged when clamped. It adopts rack and pinion drive and rotary propelling pipe cutting method, which has high centering accuracy and machining accuracy. Professional cutting system, friendly interface, easy to operate, and real-time feedback of processing status, to ensure the orderly progress of metal cutting.

The fiber laser tube cutting machine is specially designed for pipe processing customers. It has many advantages such as convenient operation, high automation, high cutting precision, and fast cutting speed. It is very suitable for the needs of large-scale industrial production of metal pipes. Tube laser cutting machines have been successfully used in fitness equipment, agricultural machinery, residential pipelines, construction machinery, vehicle manufacturing, building decoration and other metal tube processing industries.