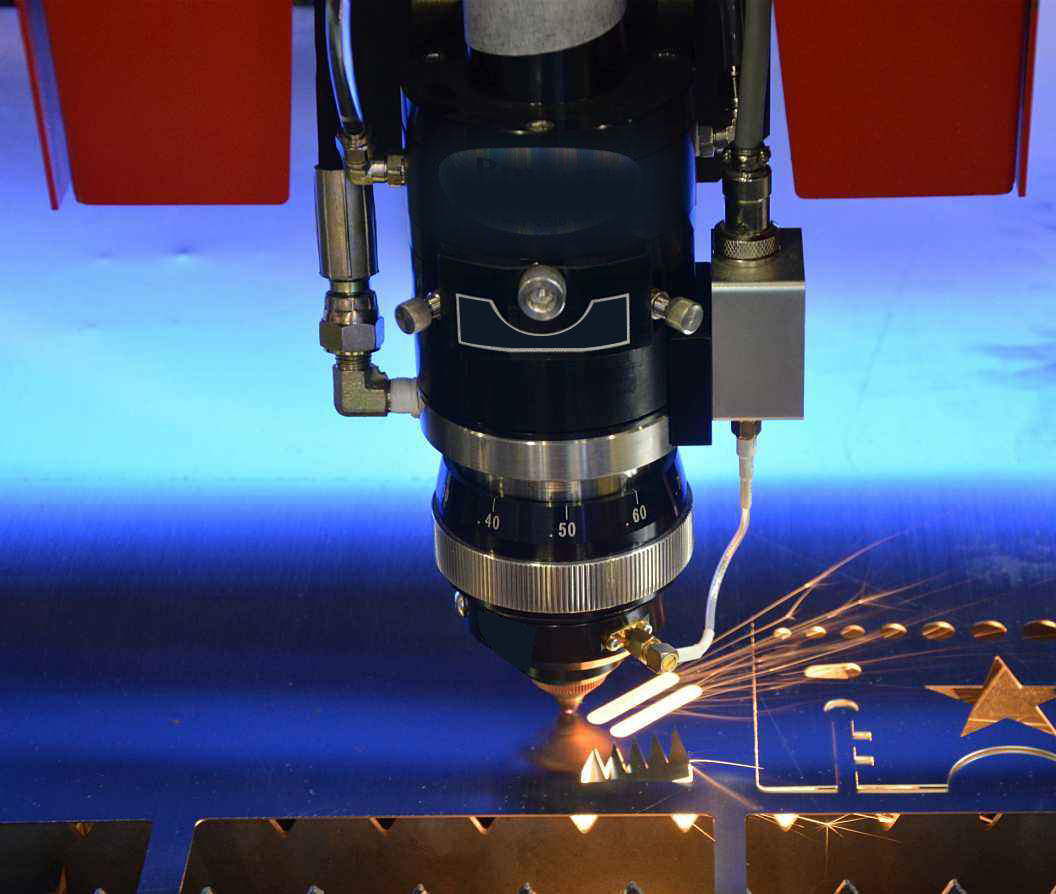

1) Melt cut

Melting cutting is another standard process used in cutting metal.But it can also be used for cutting other fusible things, such as ceramics.In this case, nitrogen or argon is used as cutting gas, with air pressure from 2 to 20bar blowing through the cut.Argon and nitrogen are inert gases, which means they don't react with the molten metal in the slit, just blow them away to the bottom.At the same time, inert gas can protect the cutting edge from air oxidation.Metals can also use nitrogen, especially titanium.Titanium reacts violently with oxygen and nitrogen, so argon is used to cut it.The great advantage of melting cutting is that there is no oxide layer at the cutting edge and no further treatment is required.However, a laser beam needs to provide all the energy needed to cut.For this reason, the cutting speed of flame cutting can only be achieved when cutting very thin sheets.Melting perforations is also difficult. Some cutting systems allow you to use oxygen piercing material and then nitrogen to cut.

2) Flame cutting

Flame cutting is a standard process for cutting low carbon steel.Flame and all kinds of oxygen used as cutting gas.Oxygen is pressurized up to 6bar and blown into the incision.There, the heated metal reacts with oxygen: it begins to burn and oxidize.The chemical reaction releases huge amounts of energy (up to five times the energy of the laser) to aid the laser beam in cutting.

Flame cutting enables high speed cutting and allows cutting of thick plates, such as mild steel over 30mm thick.However, this process also has the disadvantage that the cutting edge is covered by oxide layer.The oxide layer must be removed before the parts are painted or matte treated, otherwise the paint and coating will not adhere to the surface, without protective coating, the parts are not corrosion resistant.

3) Compressed air cutting

Pressure of air to 5-6bar is sufficient to blow away the molten metal from the incision.Since nearly 80% of the air is nitrogen, compressed gas cutting is basically melting cutting.On the surface, compressed air cutting seems to offer an economical alternative to nitrogen, since air is free.However, you must compress the air, dry it, and remove any oil that may appear.

Laser cutting has obvious advantages over traditional methods when the object is a slab, a pregnant part, or a profile.Not only sheet metal, lasers can also cut a variety of other materials, such as plastics, glass, ceramics, semiconductors and textiles, wood and paper.The types of applications are also varied.Not only for thick, solid and large parts, fine machining and micromachining are actually very popular.Experts expect applications in this field to grow substantially in the coming years.

● How to deal with soot in laser cutting and the application field of laser cutting

● How to choose a woodworking cnc machine

● Principle and technology of laser cutting glass

● Application and selection of laser cutting machine

● The applicable scope of laser cutting machine

● Buy a better 5 axis cnc router machine for your shop

Get a Free Quote Now!

Useful Link

Recommend Machine

Big discount

Headquarters: 3-1007, Minghu Plaza, No. 777 Minghu West Street,Jinan City / Branch: A2-1-1802, Hanyu Jingu, High-tech Zone, Jinan City

Factory: No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province

Copyright © Jinan AccTek Machinery Co.,Ltd