All metals suffer from corrosion in wet environments, which manifests in the form of rust. Rusting of metal equipment or metal parts can reduce its own safety and effectiveness, or even render it unusable. Faced with this situation, you will be looking for ways to remove the rust, and there are many ways to choose from. But which option is right for your product? Which cleaning technique is more effective? There are many factors you need to consider when choosing a rust removal method.

Here we show you the traditional rust removal method and the new

laser rust removal technology. You can choose the rust removal tool that suits you by understanding their characteristics.

Media jet rust removal

Sand blasting and dry ice blasting have long been used to remove rust from products as traditional rust removal methods. Derusting with media jets is a very fast cleaning solution for large surfaces affected by rust. But its shortcomings are also obvious.

Whether sandblasting or dry ice blasting, they are expensive to operate due to their high media consumption. And dry ice is expensive, as are shipping and storage costs, which means you can quickly drain your cleaning budget.

In addition to the high cost of cleaning, both sandblasting and dry ice blasting require operators to wear full safety clothing to prevent injury from debris during rust removal. When using dry ice blasting to remove rust, it is also necessary to use a well-ventilated space to avoid CO2 accumulation and endanger the life safety of operators.

Sandblasting and Dry ice blasting

Laser cleaning and rust removal

Sandblasting and dry ice blasting both use a medium to remove rust, while

laser cleaning uses a laser beam to absorb and remove rust. The laser beam can be used after power on, no other consumables, low operating cost and more convenient operation.

Removing rust with a laser is a safer way to clean. There is no flying debris, and the operator only needs to wear laser safety goggles to start rust removal, with little risk of injury throughout the job. Moreover, laser rust removal has no requirements on the environment, and can be cleaned in any environment.

The non-contact laser rust removal method will not cause damage to your metal products, and can keep the rust-free workpiece for you to prolong its service life.

Although laser rust removal has many advantages, it should be noted that there are limitations when laser rust is removed from large areas. Because laser cleaning can only remove rust in the area that the laser beam hits, you need to constantly move the laser cleaning gun to clean large areas, which can be tiring. In contrast, media jetting is faster when performing large-scale rust removal jobs.

Our laser rust removers for you

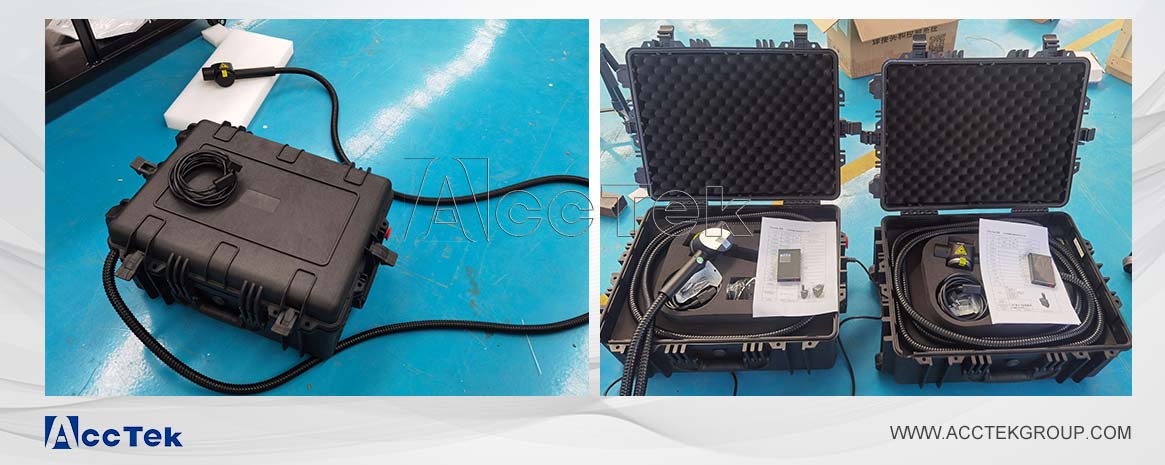

The 100W portable laser cleaning machine uses a pulsed laser generator, which can better control the heat input and prevent the substrate from being slightly soluble due to high temperature. Therefore, the 100W portable laser cleaning machine is suitable for applications with high precision and no damage to the substrate. Such as cleaning historical relics, precious works of art, precious jewelry, precision machinery and other items.

Pulsed laser cleaners range in power from 100W to 300W. The higher the power, the faster the cleaning speed.

The 1000W handheld laser cleaning machine uses a continuous laser generator, which is more suitable for industrial applications. High-power laser cleaning is faster, and the laser beam covers a wider area, which can complete a large area of rust and paint removal in a short time. The 1000W laser cleaning machine is suitable for application scenarios with large material area, heat dissipation block, and low requirements for substrate damage. Such as iron gates, iron fences, automobiles, construction machinery, large pipelines, building exterior walls and other projects.

Continuous laser cleaning machines range in power from 1000W to 2000W. This handheld laser cleaning machine has more price advantages than pulsed laser cleaning machines, and is very suitable for rust removal, paint removal, and grease removal in industrial fields.

Although laser rust removal is a new type of industrial cleaning method, it has become popular in more and more enterprises because of its advantages of high cleaning efficiency, high cleaning accuracy and low operating cost. Talk now and start your laser rust removal program.