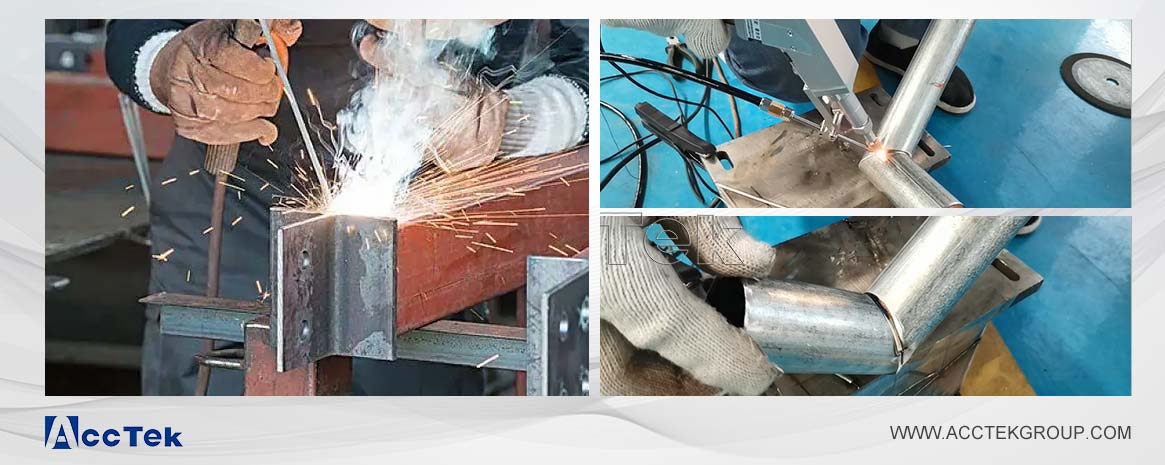

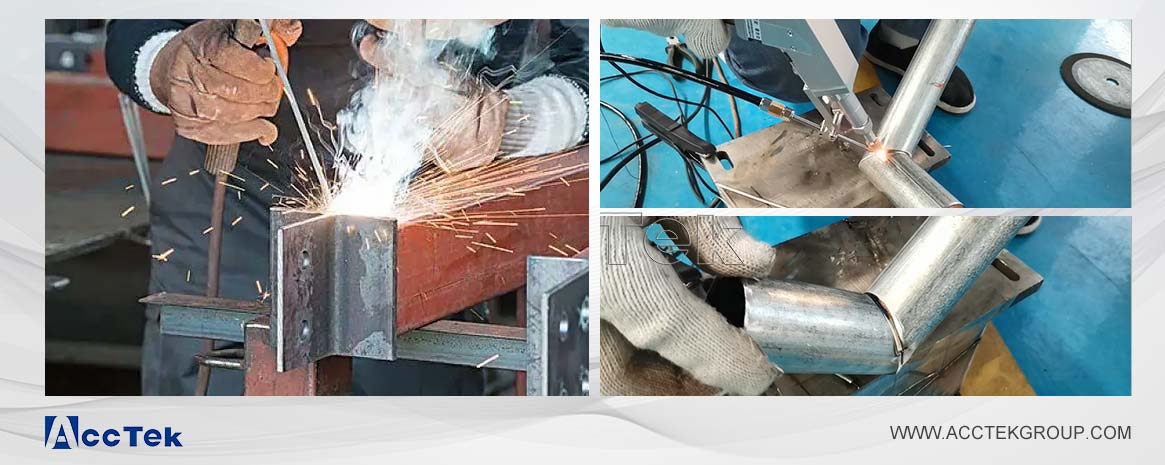

Laser welding technology is a technology recently used in most modern manufacturing. In traditional metal welding, arc welding is widely used. However, with the popularity of

laser welding machine, many manufacturers have begun to abandon arc welding and began to use laser welding metals. Many users who have not been exposed to laser welding have shown curiosity and doubts about this emerging process. Is laser welding really better than arc welding? What is the effect of laser welding? This article analyzes the characteristics and capabilities of laser welding machines from multiple aspects, and provides reference for you to choose a good metal welding method.

When the arc welding is connected to two metals, it needs to be combined with materials or filling, and laser welding can form a direct metal and metal binding without filling the material. The method of arc welding connecting metal will make the welding seams forming a slag. These slag need to be cleaned, otherwise it may pollute the application environment. Laser welding is more clean than traditional arc welding. The weld is smooth and beautiful. There is no slag to clean, so it helps reduce labor costs and reduce pollution risks. These characteristics of laser welding make it particularly important in applications such as medical equipment and scientific instruments. It does not have fragments that cause damage to personnel or precision equipment.

Another feature of the laser welding machine is that it can welded very thin metal plates (as low as 5mm) without destroying metals, which is impossible for arc welding. In terms of welding speed, laser welding is much faster than arc welding, about 6-10 times. Therefore, in the same time, the use of laser welding machines is more than the workpieces processed by arc welding. On the other hand, arc welding needs to be in contact with the surface of the material, and it will have a heat shock, which is a slow process.

Laser welding does not need to be in contact with the surface, so the aesthetics of the weld are better. Basically, you can put the next production process without secondary processing.

Of course, like any mechanical equipment, laser welding machines also have their limitations. On the one hand, it is not suitable for welding thick metal plates, such as large pipelines or structure beams. Another limit is that not every metal can be welded on other types of metal through laser. The arc welding does not have this problem because it uses filling to bond the two metals together instead of through the metal itself. In addition, the price between the two of them is also very different. The advantages of the accuracy and efficiency of laser welding machines determine that its price is more expensive than arc welding equipment. But this also means that the quality of workpieces after laser welding is higher and the productivity of the shop is higher.

Laser welding machines often use hand -held laser welding guns to start working. Its easy operation and accuracy make it more suitable for metal projects that require high quality requirements, such as medical devices, stainless steel kitchenware, home appliances, bathroom products, etc. The controllable of laser welding means that it can easily achieve automation. And welding is smaller, higher quality, faster production speed.

At present, many laser welding machine manufacturers have developed 3 in 1 laser welding equipment, and three functions of laser welding, laser cleaning and laser cutting are concentrated on one laser device. This

laser welder cleaning machine has more functions, a wider range of application, and reduced the cost of buying other devices for users.

If you are not sure which welding equipment is used before starting the welding item, you can communicate with us online. We are glad to communicate with you the best welding method, and the advantages and disadvantages of each welding method.