Rust is one of the most persistent challenges in maintaining metal surfaces, affecting structural integrity and aesthetic appeal across industries. Traditional rust removal methods, such as chemical treatments, or abrasive blasting, often have drawbacks like environmental harm or surface damage. Enter laser cleaning systems, a solution that redefines rust removal.

Laser rust removal, or laser cleaning, is an advanced method for eliminating rust, oxidation, and other surface contaminants from materials. It uses a high-powered laser beam to precisely and efficiently clean surfaces without damaging the underlying material. With unmatched efficiency, environmental friendliness and versatility, laser cleaning is quickly becoming a popular tool for rust removal.

Is Laser Rust Removal Effective?

When

laser cleaning machines first became popular, users were skeptical about this technology. People often ask, "Is laser rust removal effective?" The answer is: Yes, laser rust removal is very effective. This is reflected in various aspects such as speed, effect and safety.

Although laser rust removal technology has been available since 1990, many users are not familiar with this tool due to its high cost. Until recent years, with the advancement of laser technology, the price of laser cleaning machines has been falling, and laser rust removal has begun to enter the public's field of vision. In 2021, the price of a 1500W laser cleaning machine was more than 10,000 US dollars, but now a 1500W machine only costs 3,200 US dollars. The affordable price has made laser rust removal technology begin to gain more support from users. The effectiveness of laser rust removal is reflected in the following aspects:

Precision and Control: Laser cleaning allows for precise targeting of rusted areas without affecting the underlying metal. This precision is particularly valuable for restoring intricate designs or machinery with complex components.

Efficiency: Laser rust removal is faster than traditional methods, reducing downtime and increasing productivity. It can penetrate deeper into the rust layer and remove it more thoroughly.

Environmental Friendliness: Unlike chemical treatments, laser rust removal produces no hazardous waste, making it environmentally sustainable. It is a clever way to cut down on the negative effects on the environment.

Versatility: Laser systems can be adjusted to work on various metal surfaces, including steel, aluminum, and copper. This versatility makes laser rust removal suitable for a wide range of applications across different industries.

Safety: Laser rust removal eliminates the need for harmful chemicals and reduces the risk of injury to operators. The process is gentler than abrasive techniques, ensuring operator safety.

How does Laser Rust Removal Work?

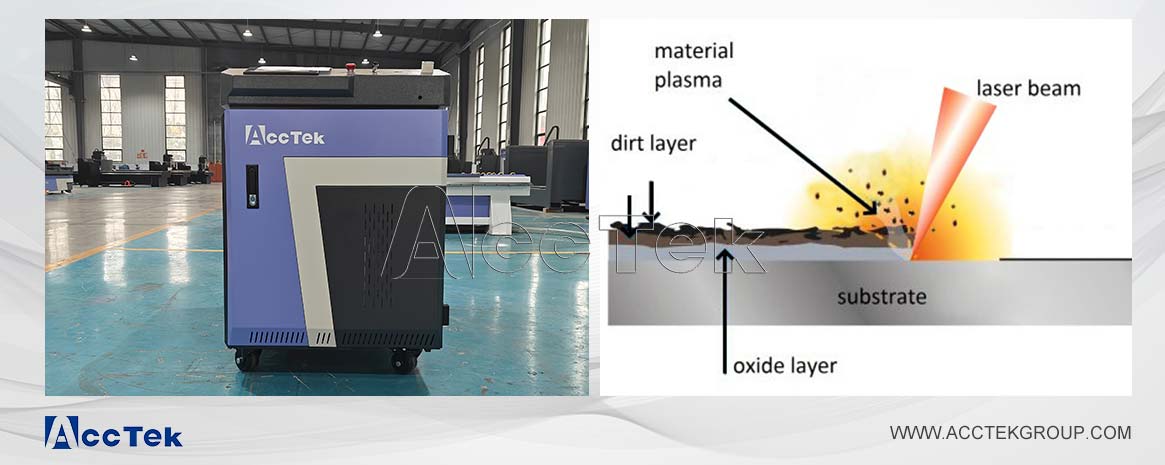

The working principle of laser rust removal is laser ablation. In this process, a high-energy laser beam is directed onto a rusted metal surface. The rust layer absorbs the laser energy, causing it to rapidly heat up and vaporize. This vaporization effectively detaches the rust from the underlying metal without causing damage to the base material.

The effectiveness of laser rust removal is influenced by several factors, including the laser's wavelength, pulse duration, and energy output. By adjusting these parameters, operators can control the depth and rate of rust removal, ensuring optimal results for different applications.

When is Laser Rust Removal Most Effective?

Laser rust removal stands out as a versatile and effective solution for tackling rust in diverse settings, ranging from heavy industry to delicate restoration projects. From industrial machinery maintenance to cultural relic restoration, laser rust removal has been proven to be the most effective in various fields.

Industrial Maintenance: Laser rust removal is highly effective in industrial settings where heavy machinery, tools, and infrastructure components are prone to rust and corrosion. This method can clean surfaces like steel beams, large mechanical parts, and industrial pipelines with precision, ensuring minimal downtime.

Automotive Restoration: In automotive applications, laser rust removal excels at restoring vintage cars and repairing vehicle parts affected by rust. The precision of laser technology allows it to clean intricate details, like car frames, undercarriages, and engine components, without damaging delicate areas.

Construction and Infrastructure: Laser rust removal is widely used in construction and infrastructure for cleaning rust from bridges, railings, and other large steel structures. Its precision and speed make it ideal for treating rusted surfaces in situ, reducing labor costs and project timelines.

Marine Industry: In the marine industry, laser rust removal can clean rust and marine growth from hulls, propellers, and structural components efficiently, minimizing downtime and ensuring that vessels meet operational and safety standards.

Cultural Heritage Preservation: Laser cleaning is an invaluable tool for restoring historical artifacts and monuments affected by rust and corrosion. Its controlled, precise application allows conservators to remove rust from metals, such as iron and bronze, while preserving the delicate details and original patina of culturally significant pieces.

Each of these areas showcases the versatility and effectiveness of laser rust removal, making it a preferred solution across various industries and applications.

Our Laser Rust Removal Machine

AccTek Laser is a professional manufacturer of laser rust removal machines in China and a trusted brand in the field of laser cleaning technology. Our comprehensive product lineup includes

backpack laser cleaning machines, luggage laser cleaning machines, and industrial laser cleaning machines, tailored to meet the diverse needs of our customers. Whether you require a portable solution for hard-to-reach areas or a robust system for industrial-scale operations, AccTek Laser has the right solution for you.

At AccTek Laser, we don’t just provide high-quality machines. Our services include professional pre-sales consultation, where our experts guide you to the ideal product based on your specific requirements. We also provide comprehensive training to help you get the most out of your equipment and offer reliable after-sales technical support to ensure uninterrupted operations.

Choose AccTek Laser to experience efficient, environmentally friendly and precise rust removal solutions.