In summer, the temperature rises in the hot and scorching heat of various places. Many laser equipment will have some heat during use. Just like when we are playing mobile phones, the mobile phone will become hot after playing with the mobile phone for a long time, and the machine will heat up. Cause some failures, so in order to avoid the

laser cutting machine failure in the use of high temperature in summer, so everyone must do a good job in the regular maintenance and repair of the

laser cutting machine, so as to extend the service life of the machine.

Let's talk about the precautions for maintaining and repairing the

laser cutting machine from three aspects.

Water cooling

In hot weather, the deterioration rate of the cooling water will also increase. It is recommended that users of the laser cutting machine use regular distilled or pure water and clean up the scale regularly to avoid the adhesion of scale in the laser and pipes that affects the laser power; pay attention to the temperature of the cooling water not to differ from the air temperature Too big. As the summer temperature gets higher and higher, the working pressure of the cooling system of the

laser cutting machine increases sharply. It is recommended to check and maintain the internal pressure of the cooler before the high temperature comes, and adjust it to adapt to the high temperature in time.

lubricating

The guide rails should be cleaned frequently to remove dust and other debris to ensure that the laser equipment is normal. The rack should be wiped frequently and lubricated. The time should be adjusted to shorten the time by 0.5-1 times compared with the spring and autumn season, and keep observation Oil condition. For machinery working in high-temperature areas, appropriately increase the viscosity level of the oil, and the temperature of the fat oil is easy to change. Add oil appropriately to ensure lubrication without debris.

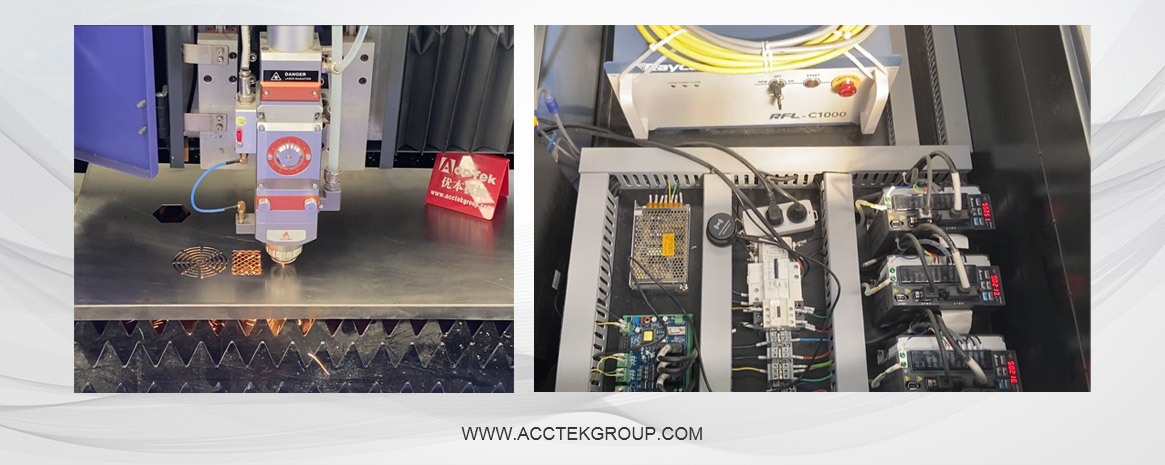

Carefully check the cutting table of the

laser cutting machine and the straightness of the track and the verticality of the machine, and if it is found to be abnormal, it will be maintained and debugged in time. The guide rail should be cleaned and lubricated frequently, and the motor should be cleaned and lubricated frequently to keep the machine in the best condition at all times. The machine can move better and cut more accurately during operation. The product quality will be higher.

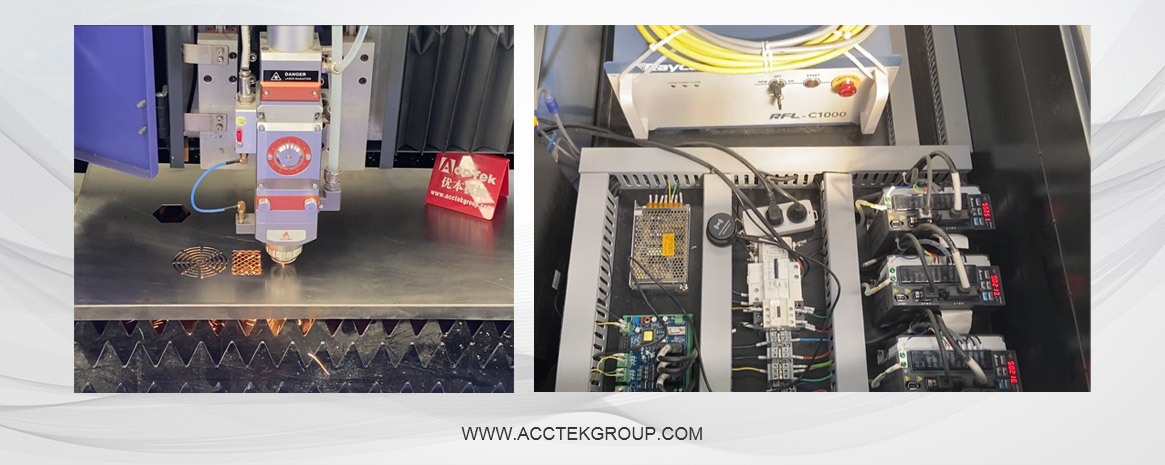

line

Check and replace the aging wires, plugs, hoses, and connectors; check whether the connector pins of the electrical components are loose, and tighten them in time to avoid poor contact causing electrical appliances to burn out and signal transmission unstable.

Reminder: Beware of the frosting of the laser machine. Because the temperature of the chiller and the ambient temperature are quite different, the laser and the cutting head will be frosted, which will cause damage to the equipment and the lens. Please increase the temperature of the water chiller, and it will not be adjusted in time. Contact after-sales and professional staff to ask how to adjust.