Fiber laser cutting machine has many advantages such as high cutting precision, narrow slit, smooth cutting surface and high efficiency, so it is very popular in the metal processing market. Moreover, with the gradual improvement of global environmental protection requirements, the environmental protection advantages of laser cutting metal are also more obvious. In the future development trend, fiber laser cutting machine will occupy the mainstream position of metal cutting equipment.

ACCTEK fiber laser cutting machines are sold to many countries and have many customers, so our engineers often encounter some questions from customers about cutting quality and cutting efficiency. Especially for beginners of fiber laser cutting machines, they will encounter situations such as low cutting efficiency and poor cutting effect, so how should we solve these problems? This article provides you with troubleshooting methods and problem solutions from various aspects, and hopes to help you use fiber laser cutting machines to process metal projects.

Effect of Cutting Speed on Metal Cutting Quality

Fast cutting speed is an important advantage of fiber laser cutting machine, but the cutting speed is not the faster the better in all cases, the cutting quality is the first consideration. In the case of a certain laser power, different sheet metals need to set different cutting speeds. Only the cutting speed that matches the cutting material can make the material section smooth and beautiful. The following methods can be used to judge whether the cutting speed is appropriate, and then adjust it appropriately.

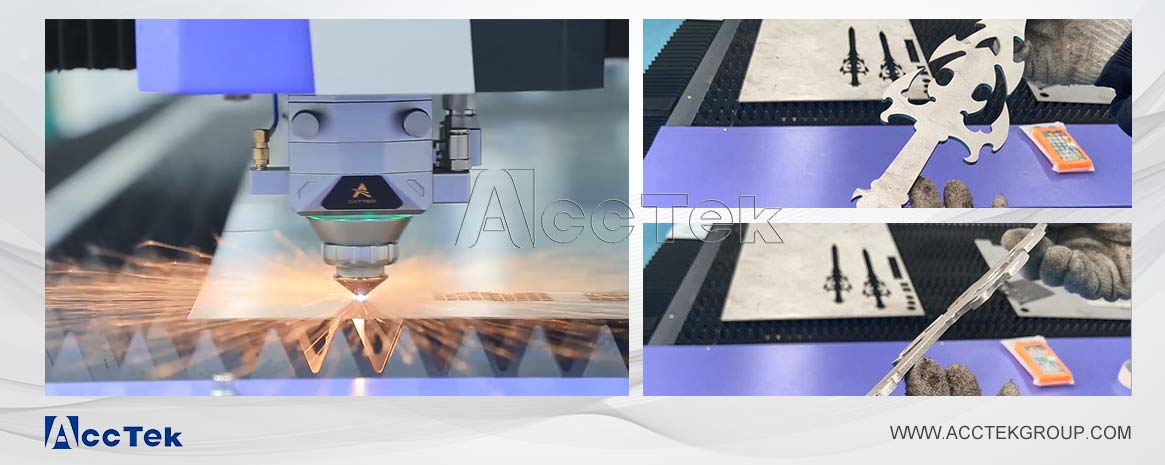

1. Judgment based on cutting sparks

If the cutting sparks are inclined, it means that the set cutting speed is too fast; if the cutting sparks gather together and do not spread, it means that the set cutting speed is too slow; only when the cutting sparks spread evenly from top to bottom, it means that the cutting speed is suitable .

2. Judging according to the cutting quality of the plate

If the plate cannot be cut through or part of the area cannot be cut through, the cutting edge is inclined and slag is generated in the lower part, it means that the set cutting speed is too fast; if the surface of the plate is over-melted, the cutting section is rough and the kerf In the case of widening, it means that the cutting speed is set too slowly; only when the cutting surface presents a smooth line, and there is no slag generated in the lower half of the section, it means that the cutting speed is appropriate.

Use the above two methods to judge whether the cutting speed affects the cutting quality, judge the cause of the problem according to the cutting sparks and the section of the plate, and then make adjustments.

Influence of Nozzle and Nozzle Height on Metal Cutting Quality

The nozzle is the channel of the laser beam and the auxiliary gas, so the shape, aperture and height of the nozzle will have an impact on the metal cutting effect. The nozzle mainly controls the cutting quality by controlling the diffusion area and size of the auxiliary gas. Generally speaking, when cutting a thin plate, a nozzle with a small diameter is used; when cutting a thick plate, the cutting seam and spot are large, and a nozzle with a large diameter is selected at this time.

Nozzles are divided into single-layer and double-layer. Single-layer laser nozzles can use nitrogen as auxiliary gas for cutting stainless steel and aluminum plates, etc.; double-layer laser nozzles generally use oxygen as auxiliary gas for cutting carbon steel plates.

The nozzle height is the distance between the nozzle outlet and the workpiece surface. When cutting metal, it is more appropriate to set this height at 0.3mm-0.8mm. If the height is too low, the nozzle will easily collide with the surface of the workpiece; if it is too high, the concentration and pressure of the auxiliary gas will be reduced, resulting in a decrease in the quality of sheet metal cutting. During the metal perforation operation, in order to prevent the generated slag from bouncing onto the lens, the height of the nozzle can be properly adjusted.

Influence of Focus Position on Metal Cutting Quality

In the actual process of cutting sheet metal, the position of the focus of the

laser metal cutting machine will be different for different materials. We need to set the appropriate focus position to obtain better metal section effects. The following is the relationship between the focus position of the fiber laser cutting machine and the material:

1. Zero focal length

The focus length on workpiece surface, suitable for cutting thin sheet metal. Because the focus is on the surface of the workpiece, generally speaking, the cut surface close to the focus is relatively smooth, while the lower surface far away from the focus appears rough. This form should be determined according to the technical requirements of the upper and lower surfaces of the metal in actual cutting.

2. Negative focal length

The focus length above workpiece, and it is mainly used for cutting thick metal plates. Negative focal length cutting of thick plates requires a large cutting width, which leads to insufficient oxygen delivered by the nozzle, which makes the cutting temperature drop, and the cutting surface is relatively rough, which is not suitable for high-precision precision cutting.

3. Positive focal length

The focus is inside the workpiece, which is usually applied to fiber laser cutting machines in cutting materials such as aluminum, aluminum alloy and stainless steel. In this mode, the airflow should be large, the temperature should be high, and the time for cutting and perforation should be long. Therefore, this cutting method is mainly used in cutting hard materials such as aluminum or stainless steel.

The way of positioning the focus length of these metal cutting needs to be determined according to the process requirements of the upper and lower surfaces in the actual situation. It is very important to determine the focus position of the fiber laser cutting machine according to the actual situation. A reasonable focus position can maximize the use of laser energy and make the metal laser cutting machine work more reasonably.

Influence of Protective Gas Pressure on Metal Cutting Quality

The size of the auxiliary gas pressure also affects the cutting effect of the fiber laser cutting machine. Adjusting the air pressure can improve the cutting quality of metal workpieces. The following are the poor cutting quality caused by two kinds of air pressure problems, which need to be adjusted according to the actual cutting situation:

1. Problems that are prone to occur when the air pressure is insufficient

When the shielding gas pressure is insufficient, the slag generated by cutting cannot be removed, and it is difficult to penetrate; the cutting speed cannot be increased, which affects the cutting efficiency. In general, high air pressure is required to prevent slag from the back of the slit when cutting thin plates at high speed; when the material is thick or the cutting speed is slow, the air pressure can be appropriately reduced.

2. Problems prone to occur when the air pressure is too high

Increasing the gas pressure can increase the cutting speed to a certain extent, but excessive air pressure will reduce the cutting speed. It is because under high pressure, too fast gas flow will enhance the cooling effect, and even interfere with the focusing of the beam energy, resulting in a decrease in cutting quality and efficiency. At the same time, when the air pressure is too high, the cutting surface will be thicker and the kerf will be wider.

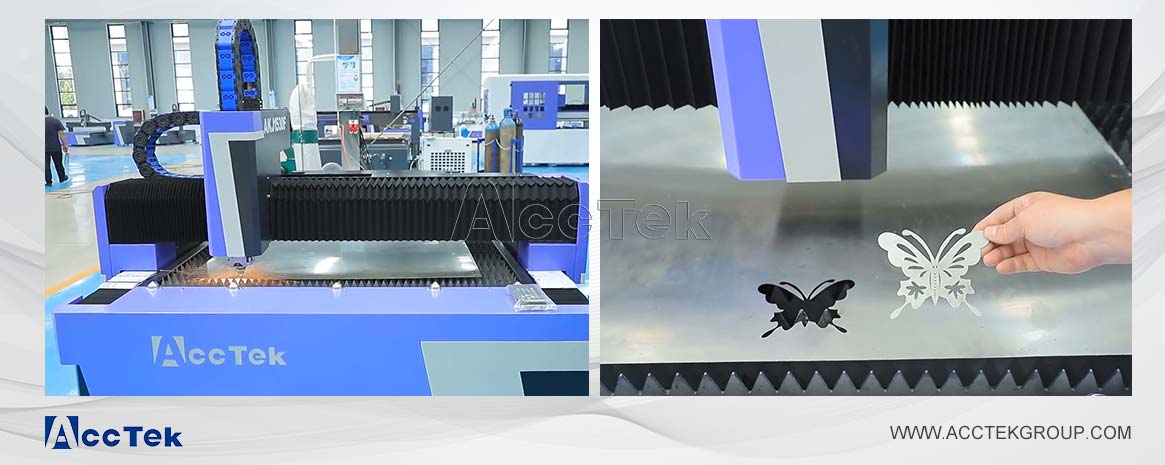

Choose an excellent

laser cutting machine, and do a good job of checking the operation of the parts before cutting. Then adjust the cutting parameters according to the actual situation during the laser cutting metal process. After a period of experience accumulation, you will definitely complete high-quality metal projects with efficient cutting speed.