Today's skilled artisans are beginning to recognize -- and embrace -- the possibilities and consistency offered by CNC routers.CNC woodworking machine tools offer a complete solution, as well as custom machine configurations, dedicated support, and a range of specially designed machine options to ensure that tasks become easier.

This advanced machine carves everything from delicate little wooden toys to elaborate designs.CNC machine tools are not only suitable for small and medium-sized enterprises, but also suitable for large workshops.

This automated and impressive technological routing machine can help increase a company's productivity and reduce its potential costs.

Modern CNC machine tools are highly automated, using CAD and CAM programs.It is with the help of these programs that it becomes easier to operate a particular machine.In CNC machines, the role of the operator has been minimized.

The operator only needs to issue instructions to the computer and load the tool, and the machine does the rest of the work automatically.CNC machine tools work like robots and you don't have to worry about accuracy.

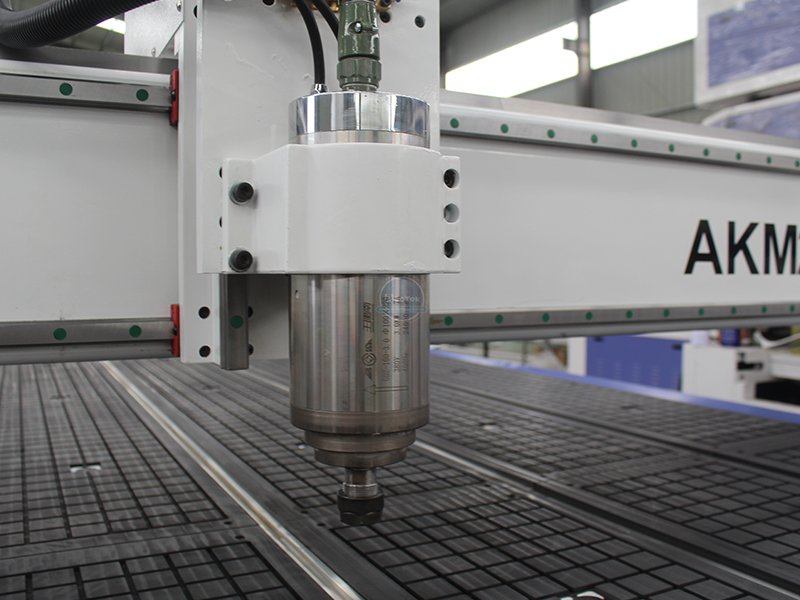

CNC machine tools can well control the movement of spindle and table.It automatically cuts, drills, etches, carves, and gives various shapes to materials. With greater precision and precision, this efficient machine meets the needs of all scale industries.

In addition, CNC woodwork can be customized with compatible optional CNC parts, helping to improve flexibility, productivity, and accuracy of the machine.

Mass production and faster reproduction of products are the backbone of CNC machine tools.Today, many manual machine tools have been replaced by CNC machines.A CNC router has the ability to sculp high-detail shapes and requires less power than a handheld tool

No matter how big or small they are, there are many safety precautions you should take when using the best machines.

CNC router machinery for your industry.

To be safe, you can use the MPGSIM button to pause the program.Mpg SIM, Feed coverage/Feed Holding is just like your friends.You can use it to stop and check your machine.To start the machine, just press the MPGSIM button and start working by keeping fast coverage at 0% and Feedrate coverage at 0%.

By pressing the Start button, you can advance the program and increase the amount of federation member overrides to 100%.Click to check how to use CNC MPG.

Insist on correct feed and speed while working with your precious mechanical parts.Make sure nothing goes wrong.Check how to calculate feed speed and speed:

The better the tool functions, the longer the tool lives.Also, if you personally set up fixtures and tools, and run the program to see if everything is working well before machining parts in it.

Before you try to operate the machine, you should know to read the manual and understand the importance of Syntec Controller, feed rewrite /Holding.

CNC routers are sold to help create a variety of objects out of wood.Most of the parts are designed with CAD /CAM programming and then cut with a CNC router.

The CAM program is primarily used to convert CAD designs into G codes, which control bits and aid in clear design.Coding language can be used to achieve cutting, carving, joint making and other functions.

CAD/CAM applications such as ArtCAM, Mastercam, BobCAD and AlphaCAM.These applications are specifically designed for wood routers.

CNC wood routers are generally larger in size than metal routers.CNC wood routers have a few advantages such as higher degree of automation, higher productivity, consistent quality, handling complex shapes, and implementing CAD/CAM applications.

The unlimited possibilities of the NC path finder

The computer-controlled wiring machine USES a variety of wooden materials and cuts out the most complex shapes, including logos, badges, fonts and so on.CNC routers provide speed and precision at an affordable price for the craftsman.

This advanced wiring machine jeopardizes the authenticity of the product and adds to the uniqueness of the furniture design.Nc wood routers also have a wide range of accessories customized and tailored to meet specific business needs.

In the production process, both accuracy and efficiency have been greatly improved.

The hardness of the wood makes it difficult for workers to do complex woodworking.However, with the development of technology, CNC machine tools are all the rage these days.

The woodworking industry now relies heavily on CNC machines for many functions.

It involves handheld routers used to cut wood and can perform many of the tasks of woodshop machines, such as cutting and producing complex shapes that are almost impossible to create by hand.Numerical control machine tool USES computer software to realize the smooth operation of the machine tool.It works in cartesian coordinates (X, Y, and Z) with three-dimensional motion control, which is almost perfectly uniform, making it easier to carve wood in complex shapes.Whether you make wood carving out of a hobby or as part of your business, CNC machines work wonders.

The task of carving and etching wood became much easier.CNC cutting machine for woodworking.Only by using CAD/CAM software to design the parts, the machine can automatically process or cut the surface to achieve a perfect dressing effect.

CNC machine tools are now in great demand.If you are also looking for perfect precision and speed at craftsman's price, then we recommend you buy.CNC routers are used to create complex shapes and designs.