Along with the rapid development of science and technology, numerical control machine tool technology is increasingly far away, now

woodworking engraving machine technology has very mature, not only on line carve, lettering, hollow out velocity accuracy, but also to improve significant effect of embossment, stereo carve, have with artificial or indifference, even higher than artificial accuracy, but the speed gap is heaven and in earth.Woodworking engraving machine factory home in the country at least also have 100, but the engraving machine that each manufacturer place produces is different, this mainly reflects in appearance and configuration go up.

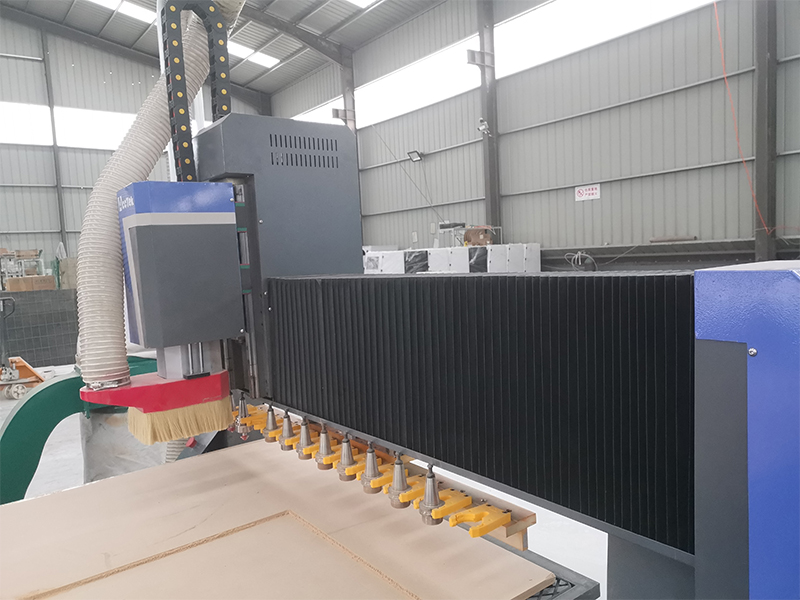

1. Spindle motor brand and power size: Famous brands of spindle motor include Italian HSD abroad and Changzhou Hanqi spindle motor in China, with power sizes of 1.52.2, 3.0, 3.7, 4.0, 4.5K or more high, different power size corresponds to different application fields. For relief sculpture, we can choose 1.5KW or 2.2kW. For cutting and cutting, 3.0kW to 9KW is the direction that customers choose.

2: guide way: guide way to woodworking engraving machine's influence mainly reflects in the precision and machine life, the famous brand has Taiwan on silver and Yintai, then there are round rail and square rail said, but now round rail has been few people again The use of guide has 20, 25, 30 points, 30 guide best, but the general woodworking carving machine configuration is 25 guide

3: fixture and vacuum adsorption: woodworking engraving machine fixed materials there are two ways :1 is fixture, 2 is vacuum adsorption, vacuum adsorption table to facilitate the loading and unloading of materials, this is an advantage, the disadvantage is high power consumption.

4. Actuators and motors: Most manufacturers choose the actuators of The Brand Of Reiser, which is also a relatively famous brand in China, and the foreign brands include Yaskawa of Japan, which involves the working mode of woodworking engraving machine, step by step or servo. If you have communicated with multiple manufacturers, you should know that the servo system is more accurate than the stepping system.

5: Frequency converter: The famous frequency converter is Fuling. The engraving machine frequency is driven by the motor of the main shaft of the engraving machine. The main requirements are stable operation and smooth rotation speed change.The full speed fluctuation is small, the low speed moment is big, may guarantee the low speed cutting

6: structure of lathe bed, bed have a light of lathe bed and heavy lathe bed, said the choice of this part is mainly aimed at the woodworking engraving machine will because when carving carving and shaking, most woodworking engraving machine Z axis stroke is 200 mm, but for some special industries such as: coffin coffin, must choose heavy body.

It is well known that the operation of

woodworking engraving machine is closely related to its control system. Summarizing the control system of woodworking engraving machine on the market, xiaobian thinks that it can be roughly divided into three categories: computer control, handle control and all-in-one machine control.

1. Computer control: install the Dimension macro control card on the PCI slot of the computer motherboard, and install the dimension macro software driver on the computer to control the walking of the XYZ axis and the rotation of the spindle motor of the engraving machine, so as to preview the processing effect and see the processing track at any time. If the program loading error can be corrected in time;Dimension macro control system is the most widely used system in the control system of engraving machine at present. The interface is humanized, the operation is simple and convenient, the function is complete, the program compatibility is extremely high, all kinds of CAM software of engraving type can be imported directly or indirectly.Disadvantage is the need for a separate configuration of a computer, but fortunately for the computer configuration requirements are very low, for the capital budget less customers, can be used to configure a second-hand computer.Now Weihong has launched a variety of different versions of control software and hardware, including multi-axis linkage.

2. Handle control, which can be held in the hand to control the movement of the engraving machine.Save space, do not occupy the computer;The disadvantage is that the operation is relatively troublesome, after all, all the functions are set in a control panel, the operation is not skilled is easy to press the wrong function key.Widely used with a variety of engraving machine (including four axis linkage), no need to occupy a separate computer, greatly reduce the equipment floor space, in addition to the knife is also more convenient.The disadvantage is that there is no preview and other functions, the interface as intuitive as the computer.

3, integrated machine control: independent integrated design, using industrial computer, PLC integrated control, rich interface, complete functions, can achieve multi-axis control and automatic tool change.Is mainly used for high-end engraving machine, machining center, and some of the mould machine carved machine, the anti-interference ability of the control system, as well as all aspects of performance, control accuracy is superior to other categories, such as the system in nc operation system and not the mainstream, but in the engraving machine control system is all-in-one such other mainstream, the disadvantage is that the price on the high side, to be more cn operational numerical control machine tool, for part of the customers' operation simple is better than the former.

For

woodworking engraving machine, three kinds of control system each has advantages and disadvantages, so we must be careful when choosing.Users who use woodworking engraving machine to open materials generally choose all-in-one machine control and industrial panel, while customers who do embossing and latticework generally choose computer control or handle control.