Laser is a very broad subject, but the laser machine we are discussing today is limited to carving or cutting equipment. Laser cutting and carving is a fabrication process. It consists of an invisible but focused laser beam that can melt, burn or vaporize materials to achieve cutting or engraving patterns.

Laser machines come in different types, sizes and power outputs. Choosing the wrong machine will bring a lot of trouble to your shop. So, how to choose the most suitable

laser cutting machine for you? This post provides you with a reference from multiple angles, and I hope it will be helpful to you.

Processing material: metal or non-metal

If you are a furniture manufacturer or clothing manufacturer, then you need a

CO2 laser machine to help your work. The CO2 laser cutting machine can engrave and cut non-metals, and can be applied to wood, MDF, acrylic, cloth, leather, stone and other materials. CO2 laser cutting machine has become the most common and popular cutting machine because of its high efficiency and low price.

If you need to carry out a metal cutting project, then you must choose a

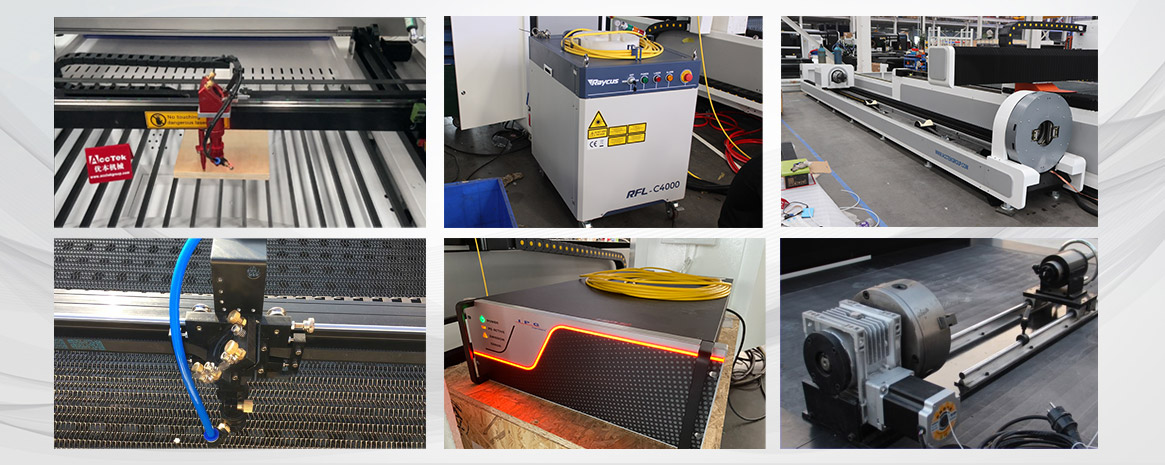

fiber laser cutting machine to work. Fiber laser cutting machine is also called laser metal cutting machine, which is professionally used in metal cutting work. The significant advantage of this laser cutting machine is that it can cut reflective and conductive metals, and there are no moving parts, they are more efficient and lower maintenance costs.

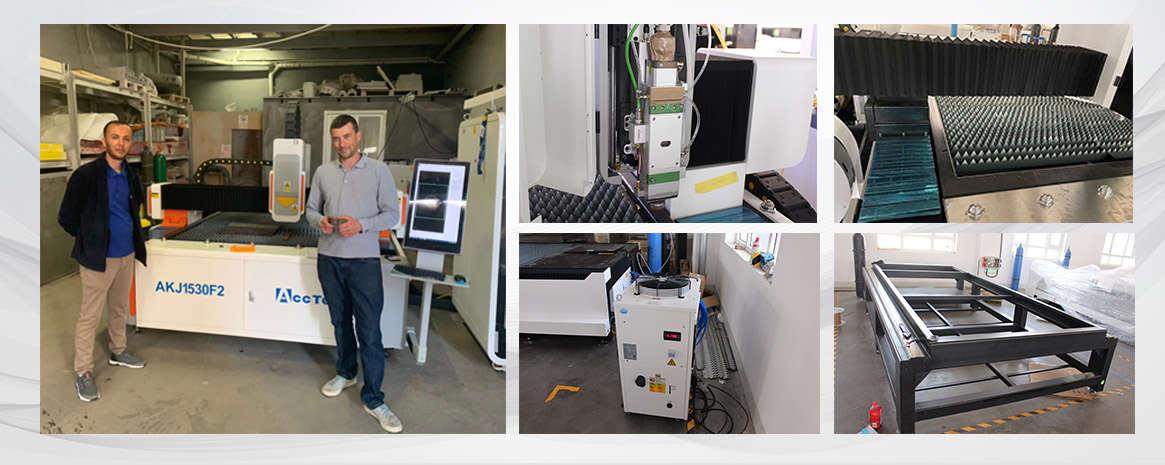

Yesterday, a Turkish user sent us feedback about the use of the fiber laser cutting machine AKJ1530F2. The cutting speed is fast and the edges of the metal material are smooth after cutting. They are very satisfied with this fiber laser equipment.

If your workshop needs to cut both metal and non-metal materials, it is very necessary to customize a personal laser machine. ACCTEK has two customized laser machines for your reference, mixed metal CO2 laser cutting machine and CO2&fiber combined laser cutting machine.

The mixed metal CO2 laser cutting machine has two cutting heads, one is used to carve non-metal materials, the other is used to cut metal and non-metal, but the metals that can be cut include only stainless steel and carbon steel. They use a CO2 laser tube to generate laser light to act on the surface of the material.

CO2 and fiber combined laser cutting machine is more widely used. The CO2 laser head can engrave and cut non-metal, and the fiber laser head specializes in cutting all kinds of metal materials. It is a powerful laser cutting machine. It has the advantages of fiber laser cutting metal with high efficiency and high precision. It can also engrave and cut non-metals like a CO2 laser machine. It has diverse functions and can process a wider range of materials.

Cutting machine table size

You should choose the work table of the laser machine according to the maximum size of the material you need to process. Commonly used fiber laser cutting machines have 4×8 feet and 5×10 feet working table. Commonly used CO2 laser machines have a table of 1300×900mm or 1300×2500mm. Of course, the table size of each machine can be customized according to your needs.

Other factors to consider

Cutting machine power: The thicker the material you need to cut, the more power you need to choose.

Work table type: If you need a CO2 laser cutting machine, you should choose to add a honeycomb table when processing soft materials such as cloth and leather to prevent the material from deforming during the cutting process.

Rotary axis device: If you need to process cylindrical materials, it is necessary to add a rotary axis device. The rotary axis can be directly placed on the machine table for use. It can engrave cylindrical materials or cut metal tubes.

It is very important to choose a cutting machine that suits the needs of the shop. You can check different types of machines according to your processing needs. Our official website has a detailed introduction of each laser machine, as well as a display of cutting videos. If you need it, you can consult online at any time.