In the cutting process of

laser cutting machine, auxiliary gas is essential! We often use oxygen and nitrogen, of course, the higher the purity of gas, the better the cutting quality.

There are also many customers who want to save cost and adopt air cutting. However, there is always water mist on the protective lens during the cutting process, and the cutting quality is poor. Why?

First, let's understand the role of auxiliary gas used in fiber laser cutting machine.

1. In order to blow away the residual waste residue and achieve the best cutting effect;

2. Can effectively achieve a smooth cutting surface, no burr, no slag effect, belongs to fine cutting;

3. Gas is used to blow away the metal slag and protect the lens to avoid the slag sticking on the lens, which will affect the cutting quality;

4. It can react with materials to increase cutting speed. For example, oxygen can be used to achieve combustion supporting effect.

Although air can be used as auxiliary gas, but because air contains water and oil, if not treated, it will cause lens pollution, cutting head instability, so that cutting effect and quality are not up to standard.

Therefore, in the use of air cutting, it is necessary to equip the

fiber laser cutting machine with a cold dryer, which can solve this problem well. The cold dryer can forcibly cool the compressed air below the required dew point temperature, so as to condense a large amount of water vapor and oil mist contained in it into liquid drops, and then discharge the compressed air out of the machine through the gas-liquid separation, so as to dry the compressed air.

Although you are recommended to inspect and clean the lens regularly, do clean it whenever you see dust on it to eliminate the risk of bad cutting results and lens breaking.

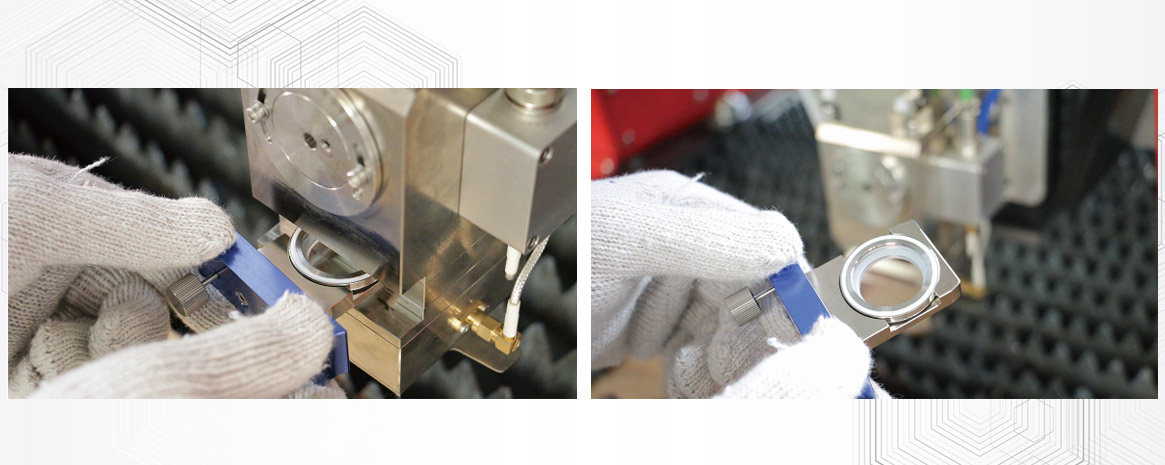

Move the working table of metal fiber laser cutting machine upward to prevent the lens from falling down on the table and breaking during removal process. Carefully remove the lens;

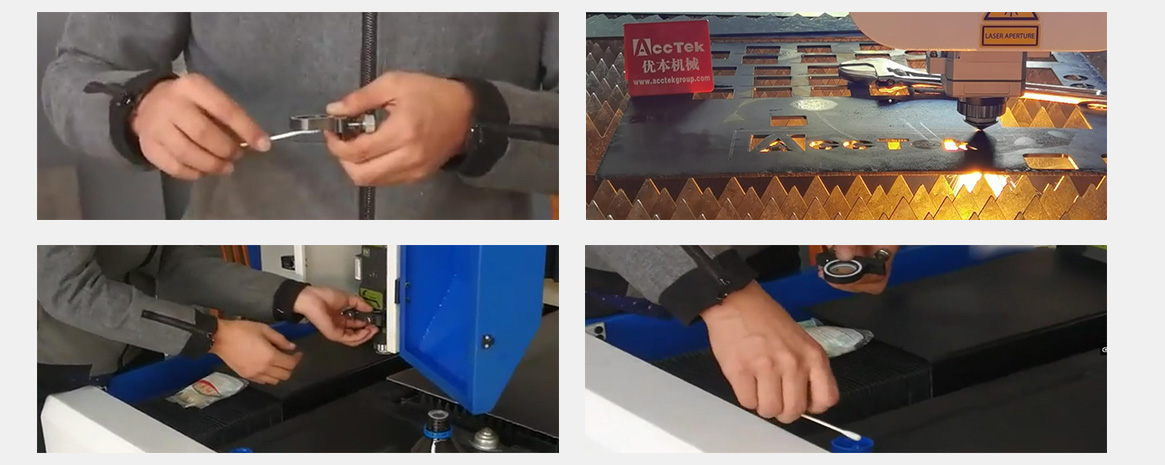

Wipe the lens in one direction with cotton swab dipped in ethanol;

Repeat for several times until there is no dirt on the lens;

Reinstall the lens on the laser head for next use.

Please note that lens and mirrors need special care when cleaning them to prevent breaking. Do not wipe lens back and forth to avoid scratching it. Do not directly wipe the dirt on the lens with fingers or rough cloth, lest it will be scratched and must be replaced with new ones.

Any machine must pay attention to maintenance while in use. The stability and normal operation of the machine are inseparable from daily maintenance. If you have other questions about the fiber laser cutting machine, you can leave us a message, our staff will reply to you in time, hope it will be helpful to you .