How much power is needed to cut 5mm stainless steel?

So far,

laser cutters have been widely promoted in all aspects of life, and the models and styles of laser cutting machines are gradually improving. In order to meet the needs of all walks of life, lasers are constantly innovating.

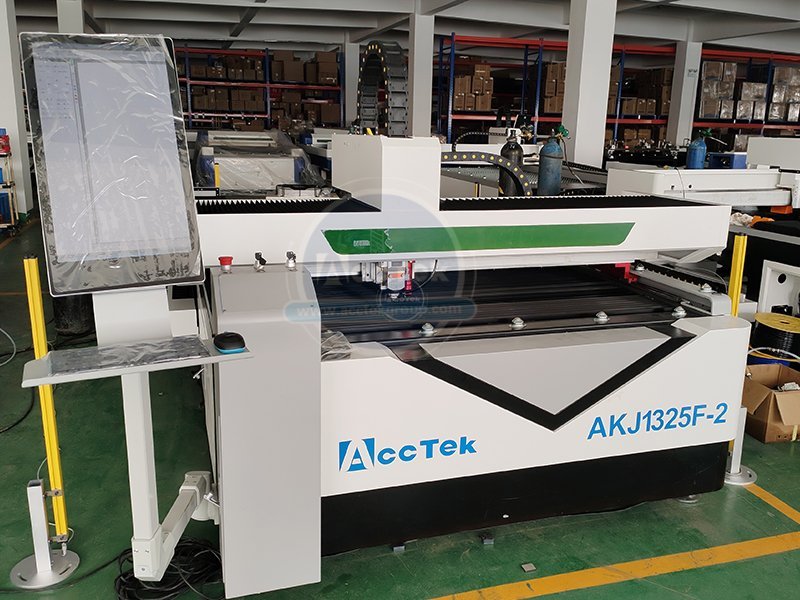

Medium and high-power metal laser cutters and fiber laser cutters have also attracted the attention of the majority of small and medium-sized enterprises. This laser cutter is mainly used for rapid cutting and forming of metal materials such as plates, carbon steel, stainless steel, etc. In the market, the power of metal laser cutter is widely used between 1000 W and 3000 W. Each laser cutting machine has its technical peculiarities and also reflects its value. When choosing a laser cutter, many customers will compare the price of the laser cutter according to the different needs of different brands. Take "the high-power laser cutter that 5mm stainless steel cutting machine needs to use" as an example to tell you how to choose your own laser cutter.

Stainless steel below 5mm is a common sheet thickness, currently mainly used in kitchens, household appliances, office supplies, file cabinets, handicrafts and other fields. However, due to the light absorption characteristics of metal materials, general laser cutters cannot be used to cut metal materials. The laser cutter puts forward higher requirements for the processing of stainless steel metal materials. The cutting of stainless steel materials must be done by a metal fiber laser cutter. Generally speaking, the 1500W fiber laser cutter can cut stainless steel within 5mm, but considering the influence of equipment wear, processing efficiency, processing quality, processing cost and other factors, it is recommended that you choose 2000 W optical fiber under a large number of processing conditions Laser cutter to cut 5mm, 6mm stainless steel materials (1500 W fiber laser cutting machine is suitable for 5mm stainless steel cutting, not large-scale processing).

1. High photoelectric conversion efficiency and low power consumption;

2. Gantry structure, plate welding machine, good rigidity, can withstand high speed and acceleration;

4. The machine tool adopts automatic partition smoke exhaust system, which has good smoke exhaust effect and low pollution;

5. Automatic programming nesting, powerful function and convenient operation;

7. Efficient cutting, free cutting and stable performance

8. The system is highly integrated, easy to maintain, and meets the needs of 24-hour industrial production.

The current fiber laser cutter equipment can make cutting easier. For some enterprises in need, such equipment can also be used to solve the cutting problem. Now, some companies no longer need to worry about the problem of workpiece cutting, they can use such equipment to complete related cutting work, and become a cutting equipment worthy of corporate attention.

What should be paid attention to when using

fiber laser cutter in different temperature environment?

Fiber laser cutters are widely used in the metal processing industry. As long as the laser cutter is regularly maintained and tested, it will generally not cause too much trouble, but in the process of use, not only need regular maintenance, but also need to pay attention to the use of the laser cutter in different environments. Many users of fiber laser cutters need to know that laser cutters should not be used in environments where the temperature is too high or too low. There are two reasons: too high or too low temperature has a large error on the cutting accuracy; secondly, it will cause great losses to the cutting equipment.

What are the requirements of the laser cutter for the working environment?

1. A series of malfunctions caused by humidity that cannot be processed in a humid environment, such as machine rust, laser malfunction, etc.

2. As a high-end equipment, laser cutter needs stable voltage and current during processing to avoid current instability and shorten the life of laser cutter.

3. For indoors, in addition to the normal working temperature, it is also necessary to pay attention to the absence of static magnetic fields in the working environment to avoid the increase of laser optical path errors.

In fact, the working environment of the laser cutter is also very important. The working environment will also make the machine unable to work for a long time and shorten the service life. Many manufacturers often ignore this point, so they should pay attention to these requirements when using laser cutters.