Whether it is a l

aser cutting machine or a

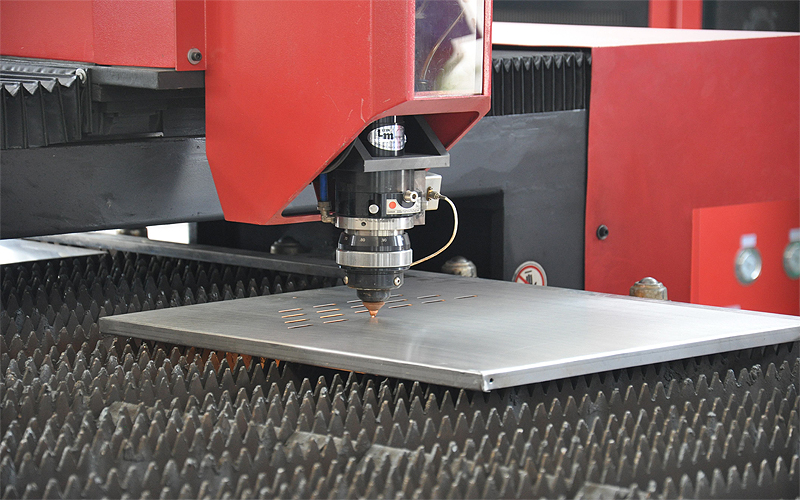

fiber laser cutting machine, the laser head is an important part of the fiber laser cutting machine. The laser head is quite the heart of the fiber laser cutting machine. The quality of the processed product is very important factor depends on the laser head The credit.

The main structure of the current laser head includes QBH, collimation part, focusing part and TRA part. Early laser heads were manually adjusted. With the changes in production requirements, the demand for automatic focusing becomes stronger and stronger. After that, an auto-focusing laser head appeared on the market.

Basic configuration of heavy-duty fiber laser cutting machine AKJ1530F3

Raytool cutting head

Swiss Raytools brand autofocus cutting head, suitable for medium and high power fiber lasers in industrial applications. Imported closed-loop motor is used to perforate and cut various material thicknesses at high speed. Automatically find the best focus instead of manual focus, which is more efficient.

Aviation aluminum gantry

It is manufactured using aerospace standards and is extruded by a 4300-ton press. After aging treatment, the strength can reach 6061 T6, which is the highest strength among all gantry frames. Light weight, high strength, no deformation. The light beam adopts integral steel mold and die-casting technology to form and frame, so that the equipment runs at a high speed, and the processing efficiency and processing quality are improved.

Raycus laser generator

Raycus has an efficient and professional R&D and production team. Now the laser output interface is QBH, which has a variety of control methods. The single-module continuous fiber laser series can not only meet the diversified needs of customers to the greatest extent, but also provide personalized customized services

Heavy frame

The strongest frame in China's CNC machine tool industry. The rectangular tube has a wall thickness of 10mm and a weight of 4500kg. Increase the stability of the guide rail and effectively avoid deformation of the bed. The life span can reach 25 years.

Silver rail

The guide rail cooperates with the sliding block to drive the machine to move. Stable operation, high-speed silent, high abrasion resistance, and good carrying capacity.

Yaskawa Servo Motor

X axis is 850W, Y axis is 1800W. Faster speed and signal feedback. Strong anti-interference ability and strong anti-overload ability. Low heat, low noise, high speed and high precision.

How does the

fiber laser cutting machine achieve focus adjustment? First, it can automatically adjust the focus. After setting the working distance of the laser head, the laser head can automatically adjust the focus. Manual focus is achieved by turning the manual focus button to achieve manual focus. Whether it is manual focusing or automatic focusing, each has its own advantages.

Note: Misunderstanding of focusing of fiber laser cutting machine

Some people think that the focal length can be changed by changing the height of the laser head. When the laser head is raised, the focal length becomes larger, and the laser head is lowered, and the focal length becomes smaller. This understanding is actually wrong.

The bottom of the laser head is the nozzle. During the cutting process, the distance between the nozzle and the plate below is about 0.5~1.5mm, and the cutting must be within this range. Therefore, it is impossible to achieve focusing by raising and lowering the laser head.