When the surface of the metal product is rusted, is there a way to remove the rust, keep the product as clean as new, and increase its service life.

Metal products are used in various scenes in life, such as car bodies, stainless steel doors and windows, outdoor guardrails, fitness equipment, etc. If metal objects are exposed to moisture for a long time, it will cause rust on the metal surface. If the rust is not removed, it will cause the workpiece to be slowly corroded until it is damaged and cannot be used, which will cause huge waste and loss.

Therefore, when the surface of the metal product is rusted, is there a way to remove the rust, keep the product as clean as new, and increase its service life.

Usually, the method of cleaning metal items after they have rusted is to use some grinding tools or pharmaceutical agents to remove the rust. But in recent years, it has been found that

laser rust removal is a better method of cleaning rust. Using a laser rust removal machine will not pollute the environment like chemical cleaning, nor will it cause damage to metal substrates like grinding tools. Laser rust removal uses a non-contact cleaning method, which is safer for the environment and the material to be cleaned. In addition, laser rust removal does not need to consume chemicals and grinding media, except for a small amount of electricity, it does not require any consumables, so the operating cost of the laser rust removal machine is very low. This is more economical for the long-term use of the enterprise.

How does laser rust removal work

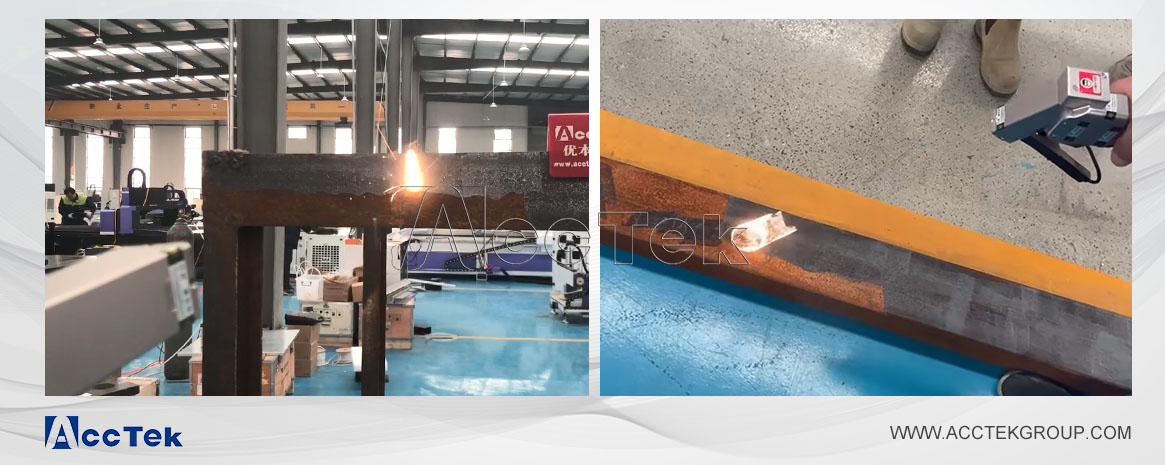

Laser cleaning technology removes rust by sending a nanosecond laser beam on the surface of a metal material. When the laser beam interacts with the rust that absorbs the laser light, the rust either turns into a gas and evaporates, or the pressure of the interaction causes the particles to break away from the surface. Experiments show that when there is oxide on the surface of the metal workpiece, the plasma is generated on the metal surface. The laser cleaning machine is mainly based on the surface pollutants absorbing the laser energy, or vaporization and volatilization, or instantaneous thermal expansion to overcome the adsorption force of the surface to the particles, so that they can be separated from the surface of the object, thereby achieving the purpose of cleaning. In laser rust removal, the light pulse width must be short enough to avoid heat build-up that would damage the surface being treated.

How to use a laser rust removal machine

Pre-startup inspection before using laser rust remover

Step 1: Check whether the power supply is AC 220V or 380V;

Step 2: Remove the handheld laser cleaning head red lens cover, check whether the lens has dust particles, wipe with the lens cleaning wipes;

Step 3: Check whether the cleaning head switch is sensitive and locked by the previous user;

Laser rust remover start-on

Step 1: Connect to the power supply to determine if the power supply is AC 220V or 380V;

Step 2: Turn on the total power supply;

Step 3: Open the cabinet door and check whether the water level is in the green area. If the water level does not reach the green area, please add pure water from the water inlet.

Step 4: Turn on the water cooler switch, confirm that the operation indicator light and the water pump indicator light are on, let the water cooler cycle for 5-10 minutes, check whether the water pipe leaks, confirm that if the water temperature reaches more than 20℃ and take the next step.

Step 5: Turn on emergency stop, on touch screen, on vibrator, and on the laser.

Step 6: Adjust the laser key gear to the ON position and the POWER lights on. If other lights indicate that the laser fails, do not proceed to the next step.

Step 7: Holding the laser cleaning gun, the position of the red cleaning head lens alignment must be an open place, the laser cleaning head is not opposite people, remove the lens cover, the cleaning head alignment to the object to clean to confirm whether there is red light, link the protection gas (compressed air), confirm the good to have red light enabling switch, press the laser cleaning head switch.

Laser rust remover shutdown

Step 1: Pull out the protective gas (compressed air) and turn off the enabling switch.

Step 2: Adjust the key switch on the laser to the OFF gear.

Step 3: Turn off the laser, turn off the vibrator, turn off the touch screen, and turn off the emergency stop.

Step 4: Wait 3-5 minutes, let the water cooler cycle for a while, when the water temperature drops below 25 °C, turn off the water cooler switch.

Step 6: Unplug the power plug.

Step 7: After all the power supply is turned off, finally confirm whether the red light lens of the laser cleaning head has dust particles. You can wipe the lens with the lens cleaning wipes and determine that the lens cover is covered if there is no dust particles.

Laser rust removal is an effective tool for cleaning metal substrates and product parts. With the correct use of a laser rust removal machine, you will find that the power of laser cleaning is unparalleled. Laser rust removal systems can clean the surface of metal products without damaging the metal beneath the surface.

Why use a laser rust remover for rust cleaning?

Laser cleaning machine provides fast cleaning and surface preparation in nearly every industry. A rust removal laser machine has other benefits besides the finer cleaning results. It is easy to operate, safe and reliable. No chemicals are needed as a medium, the running cost is low, and it is environmentally friendly.

The laser cleaning system is easy to operate and easy to learn. Even ordinary workers can complete multiple metal rust removal projects with a short period of training. This reduces labor costs, which in turn reduces operating costs. At the same time, laser cleaning can ensure the consistency of cleaning effect.

The laser is selective so we can choose to clean rusted areas without affecting adjacent materials. This saves time and money.

Laser rust removal, also known as laser surface cleaning, has become an essential cleaning method in many industries around the world. Laser rust removal is by no means the only application form of laser cleaning. Laser cleaning can also effectively remove oil, paint, cement and many other pollutants on the surface of metal parts.

Where to buy a laser rust remover

ACCTEK LASER designs and manufactures advanced laser rust removal machines. Their laser cleaning power ranges from 100W-500W low-power

pulse laser cleaning machine, and 1000W-2000W high-power continuous laser cleaning machines. Our many types of laser cleaning systems provide an efficient cleaning solution for the industry, from rust removal to paint removal, with laser cleaning, clean surfaces can be easily obtained.

ACCTEK laser rust removal machine can run stably for a long time, with strong flexibility and controllability. Online communication, you can get a laser rust removal video, and intuitively understand the laser rust removal effect.