Laser marking machine is to mark the pattern on the surface of the material, so it is also called laser engraving machine. With the continuous improvement of workshop requirements for work efficiency and workpiece quality, fiber laser marking machines are becoming more and more popular with users. Laser marking machine has the advantages of fast marking speed, low energy consumption, permanent marking, etc., which can help users to mark products efficiently and professionally.

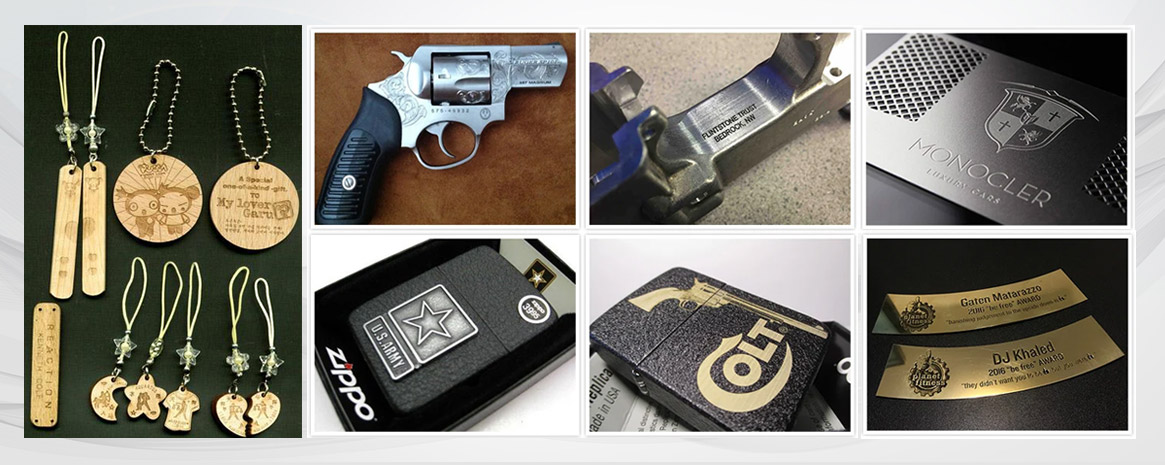

Laser marking is a process that uses a beam of concentrated light to create a precise and permanent mark on a range of surfaces, including materials like steel, titanium, copper, ceramic, glass, plastic, and wood. Be it a logo, a serial number, a bar code, a pattern or anything, laser marking machine does it all smoothly. Common uses include identifying and tracing materials, parts or machines, or marking expiration dates in the food industry.

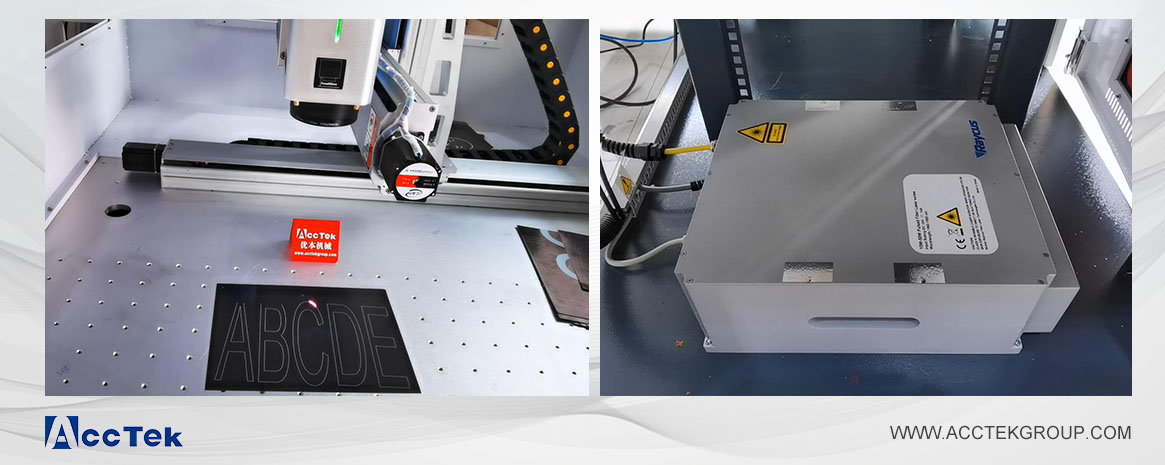

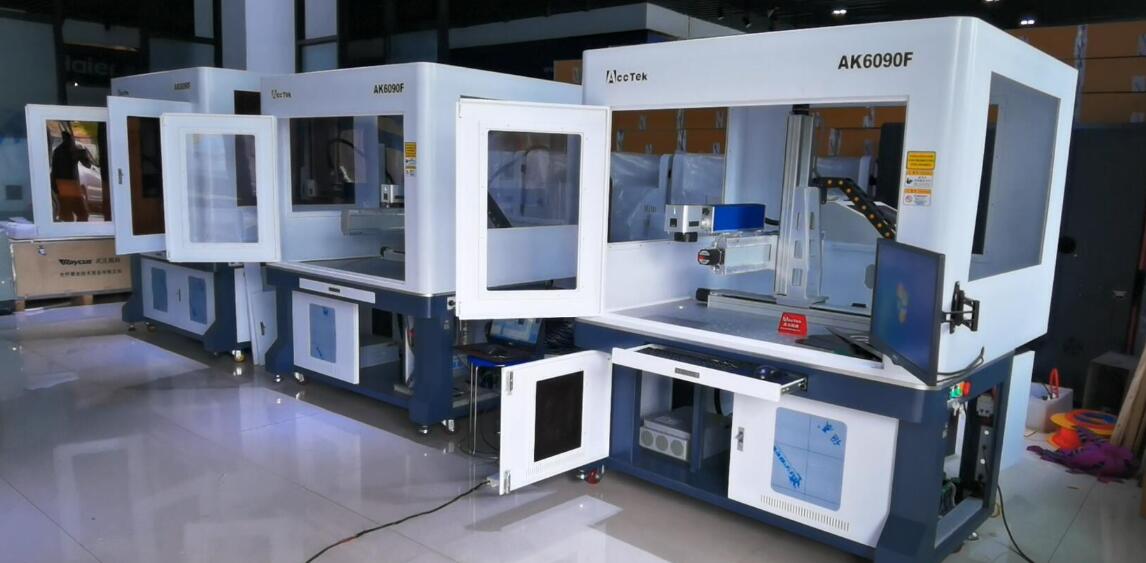

ACCTEK is a professional CNC manufacturer, the fiber marking machine produced by our factory has high precision and stable performance. It has a very high operating speed and can mark any type of information on your metal parts. The full cover fiber laser marking machine is equipped with Raycus fiber laser source, which has higher electro-optical conversion efficiency, higher and more stable optical quality, and ensures finer marking patterns.

The

laser marking machine adopts a fully enclosed cabinet, which is safer. Special control software-Latest Version Ezcad, powerful editing function, stable system, easy to operate and install. The laser galvanometer scanning head is highly efficient, high-definition scanning, and fast. Compact and convenient, durable. The working area of the AK6090F marking machine is 600×900mm, which can mark larger patterns and process large-size workpieces.

Some tips for use of laser marking machine:

1. Choose the right field lens

The larger the focal length of the field lens, the larger the focused spot. Under the same spot overlap rate, the filling line spacing can be increased, thereby improving the marking efficiency.

Remarks: The larger the field lens, the smaller the power density. Therefore, it is necessary to increase the filling line spacing while ensuring sufficient marking energy.

2. Set the delay cleverly

Different filling types are affected by different delays, so reducing delays that are not related to the filling type can also improve marking efficiency.

Bow fill and round fill: Mainly affected by the corner delay, it can reduce the turn-on delay, turn-off delay, and end delay.

Two-way filling and one-way filling: Mainly affected by the light-on delay and light-off delay, it can reduce the corner delay and end delay.

But at the same time, it should be noted that thick graphics and fonts are less affected by the delay, and the delay can be appropriately reduced. Thin graphics and fonts are greatly affected by the delay, and the delay can be increased appropriately.

3. Choose a suitable filling method

Two-way filling: The marking efficiency is high, and the effect is good.

Shape filling: It is only used when marking thin graphics and fonts, and the efficiency is similar to that of bow filling.

One-way filling: the slowest marking efficiency, rarely used in actual processing.

Bow-shaped filling: the highest marking efficiency, sometimes there will be problems with connection lines and unevenness. When marking thin graphics and fonts, the above problems will not occur, so bow-shaped filling is the first choice.

Laser is non contact process, there is no distortion. As laser marking is to gasify the surface of material, the marking will laser forever. You just need to change design in software, then all different size/shape pattern can be realized. It is very convenient for sampling or changing products.

ACCTEK as a professional CNC laser manufacturer, can provide you quality machines as well as professional solutions. You can learn more about

laser marking machines by sending us an email or talking with our online sales representatives.

Email: sales@acctekgroup.com