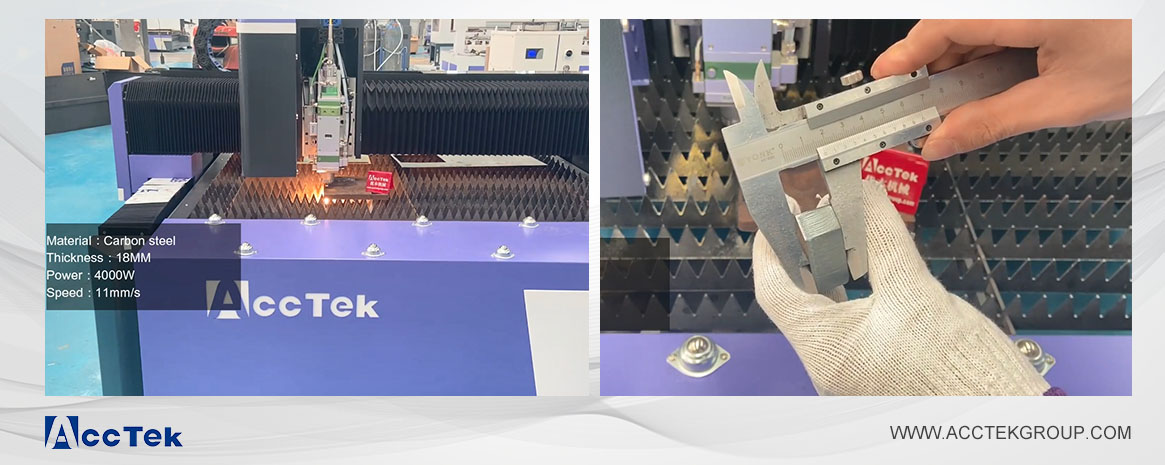

Fiber laser cutting machine is very popular for metal projects, and it has very good results in cutting common metals such as stainless steel and carbon steel. With the advancement and innovation of technology, people have a demand for laser cutting highly reflective materials, such as copper, brass, aluminum, and these metal materials are more and more involved in industrial applications.

Can fiber laser cutting machine cut highly reflective metal materials?

Fiber laser cutting highly reflective metal materials is not as easy as cutting carbon steel. The problem stems from their properties and has to do with the laws of optics. According to this law, every beam of light is reflected and refracted (and absorbed) to a greater or lesser extent, depending on the forces on the surface of the material. Therefore, if the metal surface is highly reflective, the beam emitted by the fiber laser cutting machine will be reflected a lot. This may damage the laser generator.

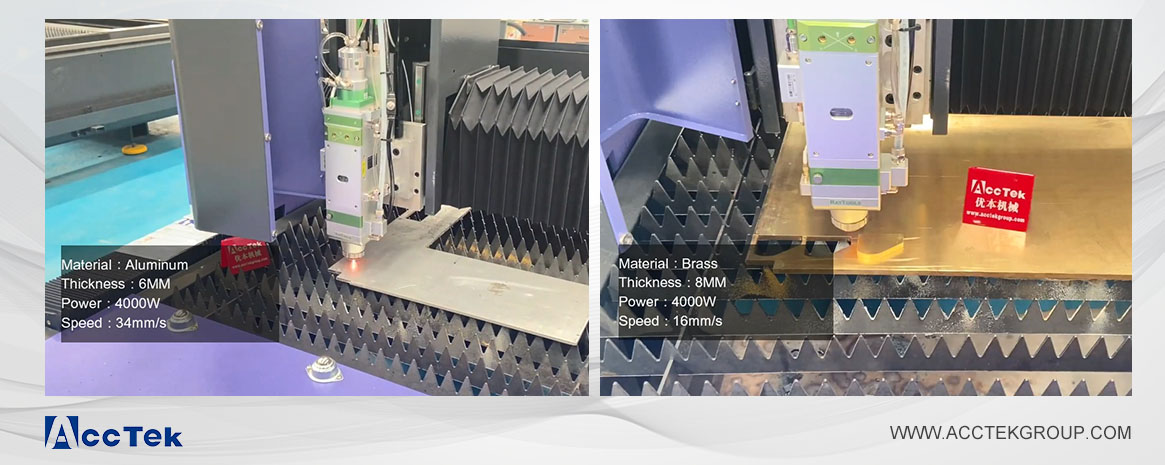

Although there are certain problems in cutting high-reflection metals with fiber laser cutting machine, it does not mean that fiber laser cutting machine cannot cut high-reflection metals. As long as it is equipped with a suitable laser generator and adjusted with reasonable parameters, high-reflection materials can also obtain good cutting results. The

fiber laser cutting machine equipped with 4000W IPG laser source produced by ACCTEK factory is used to cut 6mm aluminum and 8mm brass with good cutting effect.

What are the factors for the success of fiber laser cutting brass?

Cutting speed

The maximum feed rate that the process can support is reduced by approximately 10 – 15% to avoid any risk of cut extinction, thereby applying high levels of beam energy to the most reflective materials. When in doubt, start at a slower speed than the process you know can support. Allow enough dwell time to ensure that the pierce passes through before moving the beam to start cutting.

Focus position

For laser piercing and cutting, set the focus position as close to the top surface as the quality of the cut allows. This minimizes the amount of surface material that interacts with the beam at the beginning of the process, thereby maximizing the beam's power density and speeding up melting.

Power settings

Using the maximum peak power available for piercing and cutting reduces the time the material is in its most reflective state.

Cutting gas

High pressure oxygen (100-300 psi, depending on thickness) is typically used as the cutting gas when piercing and cutting copper to improve process reliability. When oxygen is used, copper oxide that forms on the surface reduces reflectivity. For brass, nitrogen cutting gas works well.

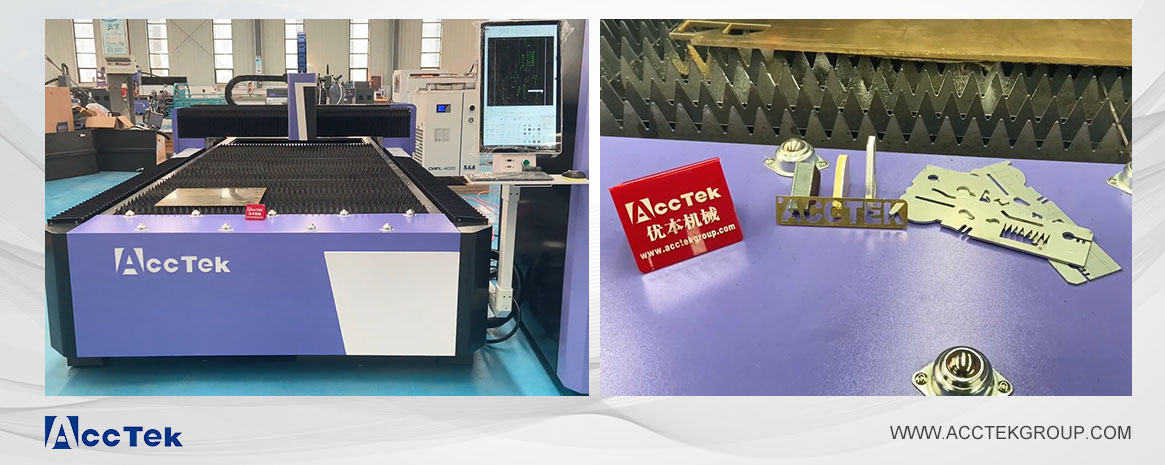

Today,

fiber laser cutting is such an important process in sheet metal processing that it largely surpasses traditional techniques for cutting metal. To achieve good metal cutting results, proper power and parameters are very important. ACCTEK will provide you with technical support while providing you with the machine, so that you can become an experienced laser machine operator faster.