Not everyone is unfamiliar with acrylic, because its clarity and ease of processing are highly praised by many industries. Acrylic materials are not only three-dimensional, high transparency, but also cold and heat resistant, corrosion resistant, and have a long service life. They are generally used for suspended ceilings, integrated ceilings, partitions, screens, sliding doors, transparent walls, hotel furniture, office furniture, bar counters, lighting, Chandeliers, signs, advertising signs, floors, landscapes, etc.

The thickness of the acrylic sheet is usually 3-20mm. For this reason, the traditional cutting and engraving processing methods adopt molding and mechanical

engraving cutting, which not only has a long production cycle and low processing accuracy, but also has a complex processing flow and poor results. Often unsatisfactory can not meet people's treatment requirements.

Let's take a look at some products of cnc router applied to acrylic materials, let everyone intuitively feel what convenience

cnc router brings us?

1. How to use cnc router to engrave billboard fonts?

Advertising signboards need to be made into different colors. These colors need to be completed by the corresponding engraving process. Acrylic materials have good coloring properties, which can adapt to a variety of different types of surface treatment processes, and the complexity is also low. It is not too high, and most manufacturers can implement it through cnc router, so this is also an important reason for the large number of acrylic backs used in the field of door-to-door advertising signs.

After advertising signboards have colors, the radiant light will usually be more attractive and commercial value than signboards made of other materials.

This economic performance is reflected in two aspects. On the one hand, acrylic itself is relatively cheap and the cost is not high. In addition, because acrylic has good light transmission performance, the utilization rate of the light source is relatively high. Under the same power light source , The door-to-door advertising signs made of acrylic will generally have better effects. In fact, they have the advantage of energy saving and electricity saving. For large commercial establishments, the electricity bill itself is a kind of cost, and if the advertising sign can save a little on the electricity bill A fee, which is very happy to see for merchants.

2. How are colorful crafts made by engraving machine?

The advantages of choosing acrylic crafts are as follows:

First is the good light transmittance: this is the primary condition for our choice of acrylic products. It is said that the light transmittance reaches 92% so that we only lose about 8% of the heat, and we can absorb most of the heat energy. Of course, anti-corrosion Ultraviolet rays and the like are indispensable.

Long lifespan: This is also very important. The lifespan is more than three years longer than ordinary glass, so that there will be no aging or yellowing due to sun exposure, which is beautiful and generous, and saves money.

Convenient to clean: Good things generally need maintenance and maintenance. Acrylic is also very advantageous in this respect. We can easily remove traces of acrylic products by scrubbing with a soft cloth. There is also dryness and frequent dust. Acrylic is here. Dot can be said to be a unique advantage, and it can restore its original brightness with a simple wipe.

Environmental protection: This is very useful in the long run. People are becoming more and more aware of environmental protection. At the same time, it is generally believed that products that waste resources and pollute the environment are definitely harmful to the health of the body. Acrylic is very environmentally friendly in this respect, not only does not pollute the environment. , And the recovery rate is high, and the reuse of resources saves resources.

3、Application of engraving machine in lamps and lanterns

The acrylic lamp has strong light transmittance. Acrylic sheets used in the outdoor advertising industry have extremely good light transmittance. With the built-in light source, the brightness at night is uniform and soft. Compared with neon lights, the acrylic characters emit light as a whole, unlike neon lights, which have lines that emit light and are softer than neon lights.

As everyone knows, the acrylic plate is vacuum positioned and formed by suction. Even if it is the same character and different sizes, different molds are required, and the mold making itself requires high precision and high quality.

Therefore, it is very important to choose a good mold

engraving machine, because the precision and quality of mold making itself are directly related to the quality of acrylic products, and mold making has a high level of craftsmanship and requires experienced technicians. Therefore, as mentioned above, the current market blister light box has always been at a high price, and the processing of the mold should be said to be the most important cost.

Therefore, the application of

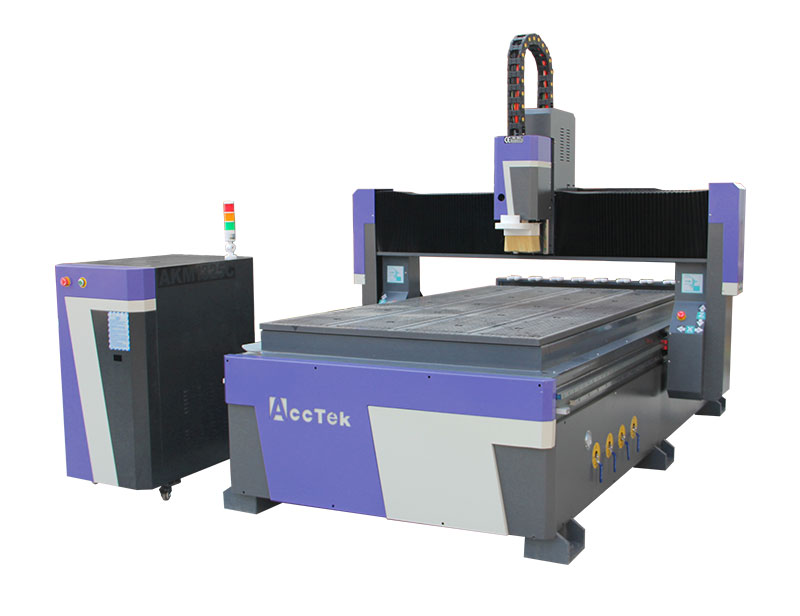

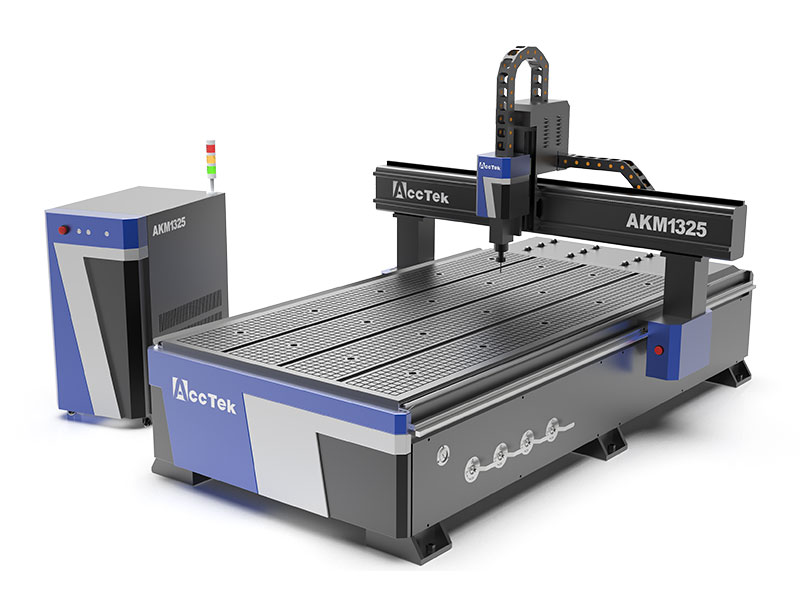

cnc machine has brought unlimited possibilities to the acrylic industry. The use of non-contact processing can minimize the deformation of material processing. Laser processing can be used for engraving processing because of its high precision, no cracks in the cutting joint, and smooth cutting. Generally, no post-processing is required, and patterns and shapes that cannot be supplemented by traditional methods can be made. The second is the use of engraving machine, because it can not only improve production efficiency, but also save labor costs, suitable for mass production.