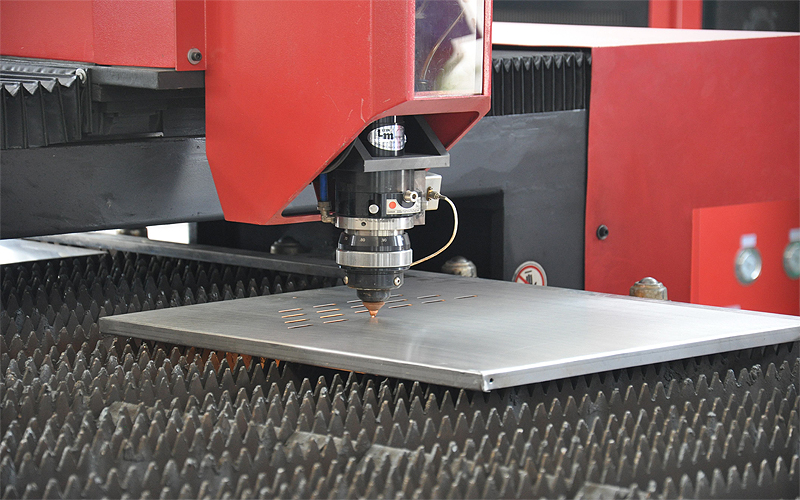

The daily maintenance and maintenance of laser cutting machine is very important.The following are mainly explained from five aspects:

1) replacement of circulating water and cleaning of water tank: the laser tube must be filled with circulating water before the machine works. The quality and water temperature of the circulating water will directly affect the service life of the laser tube.So periodically replace the circulating water and clean the water tank.This is best done once a week.

2) fan cleaning: when the fan in the machine is used for a long time, the minister fan accumulates a lot of solid dust, which makes the fan produce great noise and is not conducive to exhaust and odor elimination.When the fan suction is not enough smoke, it is necessary to clean the fan.

3) cleaning of the lens: there will be some mirrors and focusing mirrors on the machine.The laser is reflected through these lenses, focused and emitted from the laser head.Lens is easy to get dust or other pollutants, resulting in the loss of laser or lens damage, so you need to clean the lens every day.

4) fastening of screws and couplings: after the movement system works for a period of time, the screw coupling at the movement connection will become loose, which will affect the smoothness of mechanical movement. Therefore, it is necessary to observe whether there is abnormal sound or abnormal phenomenon in the transmission parts during the operation of the machine. If any problem is found, it should be strengthened and maintained in time.At the same time, the machine should tighten the screws one by one with tools.

5) light path check: machine light path system is made of mirror reflection, together with the focus lens focusing focus lens in the optical path was not found deviation problem, but the three mirrors is composed of mechanical part is fixed, the possibility of deviation is bigger, although usually does not happen, but suggest user before each work be sure to check the light path is normal.The lubricating oil filling of X axis guide and lead screw, Y axis guide and lead screw, Z axis guide and lead screw must be checked every other week to maintain the lubrication of all moving parts and extend the service life of X axis, Y axis and Z axis guide and lead screw.B. Inspect the surface pollution of the reflector and the focusing mirror irregularly (at least once a month) according to the workshop environment, and clean the optical lens in time to ensure its service life (see optical lens maintenance for details).Check the filter in the air path regularly, and remove the water and sundries in the filter timely.Regularly check whether the travel switch bracket and the bump bracket screw are loose.Clean up the dust on the filter network of the ventilation fan of the electric control cabinet in time to ensure good ventilation so as to facilitate heat dissipation of the internal electrical components.Clean the body in time for bed guide rail protection leather cavity debris, so as not to damage the guide rail, thereby extending the service life of the guide rail.After the machine tool is installed and used for a period of time, the level of the machine should be adjusted again to ensure the machine tool's cutting precision lens cleaning. In the process of replacement, the placement, detection and installation of optical lenses should be paid attention to to protect the lens from damage and pollution.After installing a new lens, clean it regularly.When the laser cuts through the material, the working surface releases a lot of gas and splashes, which can harm the lens.When contaminants fall on the surface of the lens, they absorb energy from the laser beam, causing a thermal lensing effect.If the lens has not yet developed thermal stress, the operator can remove it and clean it.In the process of lens installation and cleaning, any sticky matter, even nail oil drops, will increase the lens absorption rate and reduce the service life.Therefore, the following precautions must be taken:

1. Never install lenses with bare fingers.Finger gloves or rubber gloves should be worn.

2. Do not use sharp instruments to avoid scratches on the lens surface.

3. Do not touch the film layer when taking the lens, but hold the edge of the lens.4, the lens should be placed in a dry, clean place to test and clean.

Doing the above can effectively reduce the possibility of lens contamination.The cotton ball dipped in acetone must be cleaned under light and moved in a ring.Once the cotton swab is dirty, it must be replaced.The cleaning should be done all at once to avoid the generation of wave tendons.If the lens has two coated surfaces, such as a lens, each surface needs to be cleaned in this way.The first side needs to be placed on a clean sheet of lens paper for protection.If acetone does not remove all dirt, rinse with vinegar.Vinegar cleaning is used to remove dirt by dissolving it, but does not harm optical lenses.The vinegar can be experimental grade (diluted to 50% strength) or household white vinegar with 6% acetic acid.The cleaning procedure is the same as acetone cleaning. Acetone is then used to remove the vinegar and dry the lens. Cotton balls should be changed frequently to fully absorb the acid and hydrate.Until it's clean.When contaminants and lens damage cannot be removed by cleaning, especially when the film is burned out due to metal splashes and dirt, the only way to restore good performance is to replace the lens.

Electrodes and nozzles are the biggest consumables in the daily operation of

CNC plasma cutting machine, especially the original imported electrodes and nozzles.Therefore, effectively extending the service life of the electrode and nozzle will greatly reduce the production cost of plasma cutting.The consumption of electrodes and nozzles is related to various factors such as air pressure, cooling water pressure, voltage, current, air supply quality and the quality of consumable parts. Some abnormal consumption caused by machine failure must also be paid attention to.I have encountered the phenomenon of frequent burning of complete sets of electrodes and nozzles at the moment of arc ignition of cutting machine, and some burning within 0.5~1h after cutting, which are not normal consumption.