The industry is changing fast.To maintain this speed, the machine owner needs to update himself with any new information available.In addition, they need to understand the coming model, upgrade their Arsenal with the machine of the future, or raise funds to plan the purchase of the machine.

CNC machine tools provide a fast and skilled method of cutting and carving objects.In addition, the use of laser machines because sheet metal cutting equipment can be a very powerful way to give a company a dominant position in the market.It is more of a statement that the owner is ready to deliver the product in a timely and efficient manner.

However, we cannot ignore optical fiber laser cutting machines when the topic of discussion is about CNC machine tools.This is an upcoming and futuristic part to ensure success.But what is this machine really about?Maybe it's time to decipher it!

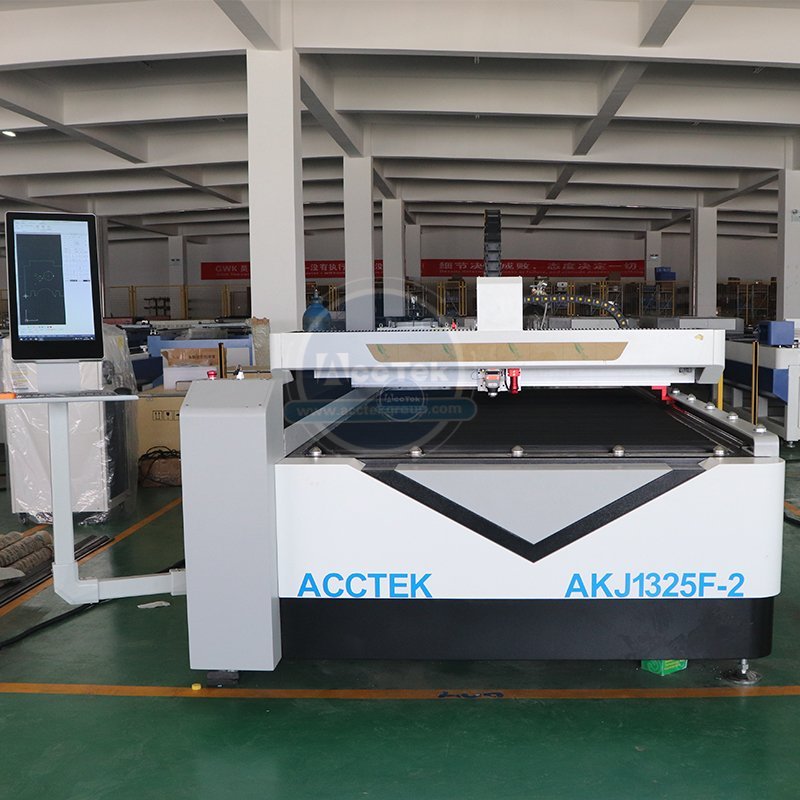

A optical fiber laser cutting machine is A kind of laser cutting medium, production of high quality, high speed, high efficiency, high precision CNC machine tools.These fiber optic laser cutters are a perfect complement to the metal processing operator's Arsenal.

However, most of the best machines use lasers with power of 1500, 2000, 3000, 4000, 6000, 8000.Power is an important factor affecting the working quality of optical fiber laser cutting machine.Such as stainless steel, electrical steel, aluminum zinc plate, galvanized steel plate, titanium alloy, iron, brass, copper and other metals of different thickness, the power of more than 1500 W or equal to 1500 W fiber machine for special cutting.

However, less powerful machines such as 500 W, 750 W and 1000 W can be used to produce fancy designs that do not require many cuts or penetrations.

How does it work?

Looking ahead, many buyers don't want to learn much when they buy the machine, one of which is how it works.It's always good to have some extra knowledge, especially about how machines work.

The machine runs on a laser fired by a fiber optic laser generator.The laser is generated by an optical path that focuses the optical fiber laser beam on the material in use and has a high power density.The laser beam then shines on the surface of the metal, bringing it to its melting or boiling point.In this process, the high-pressure gas is connected to a fiber optic laser beam and blows away the molten or vaporized material.

In all of these processes, the laser beam is aligned with the metal to cut through the material.

As mentioned earlier, it is important to understand the depth of the pool.That's why people should know the cost of fiber optic laser cutting machines.In addition, knowing why you chose this machine is beneficial for beginners.

In addition, finding a professional or guaranteed fiber optic laser cutter company is also a good start.These professionals know the nuances you don't and can guide you to buy laser machines at a very good and affordable price.

However, the most critical aspect of a CNC fiber laser cutter is its ability to perform the specified job.The machine should operate with high precision and high speed to provide the highest quality of work.In addition, look for a company with a highly rated and trusted brand in the market.This will ensure that they are supported and backed up whenever there is a problem with the machine and also in a short time!As a professional, the company likes CNC's commitment to providing excellent technology and to promoting the development and production of this work.

In addition to knowing the cost, people should also know where these machines are in modern shops.Optical fiber laser cutting machine is a large machine, which needs to be processed in a system environment with high quality.Perhaps this is why finding a good level of refinement and sophistication is a valuable aspect of buying this machine.

Versatility and high efficiency are the two main characteristics of this machine, regardless of any power.A medium (750 W~1500 W) fiber optic laser cutter is a valuable asset for those concerned with cutting materials of all thickness.These machines can cut up to 0.70 inches of steel, 0.315 inches of aluminum, 0.394 inches of stainless steel, and 0.197 inches of copper and brass without changing lenses.

Speed and adaptability are the two main principles, as well as the aforementioned machine.This helps to finish the work on time, thus eliminating the extra expense on the final product.However, there are some burdens, such as replacement costs and downtime costs, that operators can eliminate.In addition, taking all other factors into account, a fiber optic laser cutter cuts twice as fast, is one-sixth the cost of a CO2 laser, and has a payback period 70% of that of a CO2 laser cutter.

Fiber optic laser cutting machine reduces waste and improves the quality of finished products for the following reasons.First, it benefits from a very stable beam platform.This platform remains constant and helps maintain cutting quality, regardless of the distance between the nozzle and the metal plate, which is under the cutter.

Secondly, the narrow cut and small spot size of the fiber laser help to achieve the required high speed cutting without sacrificing the working quality.