Laser technology has developed very rapidly in recent years, the most representative of which is the

laser cutting machine. Among them, the CO2 laser cutting machine was invented in the 1970s and applied in the field of industrial production. The fiber laser cutting machine is limited by technology, and it did not mature until the 21st century, and it has developed rapidly in the past ten years. The prices of these two laser cutting machines are very different, because their cost and application fields are very different. This article introduces several CO2 laser cutting equipment suitable for small businesses.

Before introducing the application of CO2 laser cutting machines, let’s first understand the working principles of the two laser cutting machines, so that we can better understand the reasons for the huge price differences between them and their respective application ranges.

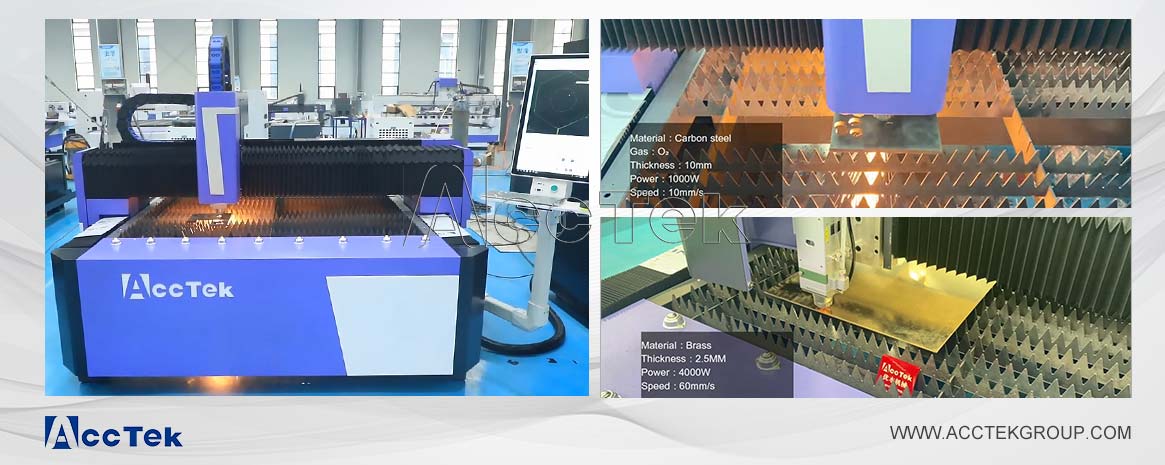

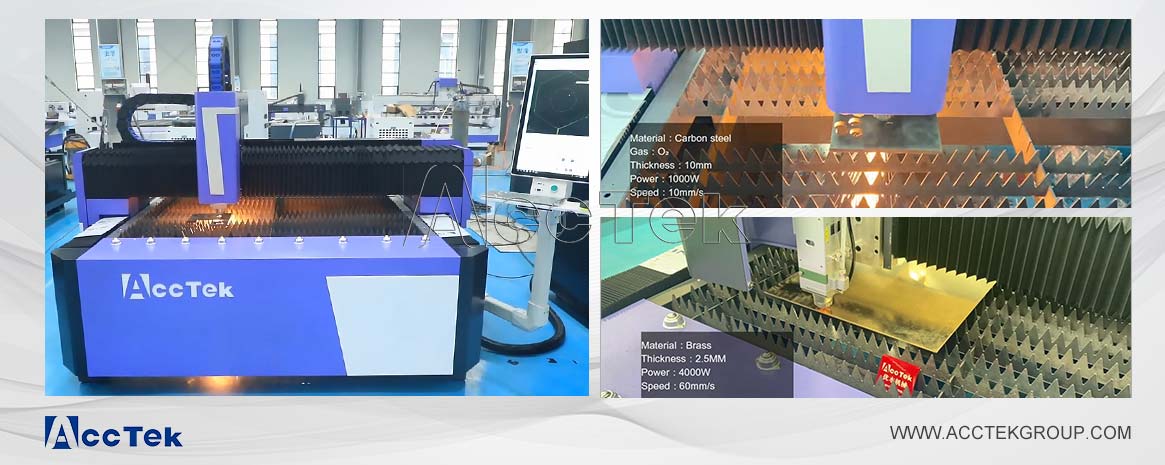

The fiber laser cutting machine uses a fiber laser generator to emit a high-density laser beam and transmit it to the surface of the sheet metal. The generated laser heat is absorbed by the material, and when the temperature of the workpiece reaches the boiling point, the material is melted and penetrated. As the position of the beam moves on the surface of the workpiece, the route irradiated by the laser beam will form a slit on the sheet metal, and finally achieve the purpose of metal cutting. From here we can understand that fiber laser cutting machine is a kind of CNC laser equipment professionally used for metal sheet processing. It is suitable for production in the field of heavy industry.

So how does the CO2 laser cutting machine work? In fact, its working principle is very simple, using laser power to drive CO2 laser tube to emit light. Through the refraction of multiple mirrors, the light is transmitted to the laser head, and the focusing lens installed on the laser head converges the light into one point. When it reaches a very high temperature, the material is sublimated into gas immediately, and then sucked away by the exhaust fan, so as to achieve the purpose of cutting and engraving. CO2 laser cutting machine is professionally used for the processing of non-metal materials, it can also cut metal, but only limited to stainless steel cutting. Therefore, the application of CO2 laser cutting machine is very extensive, and it is more used in some small light industrial fields. Here are several CO2 laser cutting machines suitable for small businesses.

Small CO2 Laser Cutting Machine

The small

CO2 laser cutting machine is a very popular CNC laser equipment in the advertising industry. Its size is usually 1390, that is, the worktable size is 1300×900mm. This CO2 laser cutting machine adopts aluminum strip table, which has higher load-bearing capacity, and is mostly used for processing hard materials, such as acrylic, wood, etc. These two materials are the most widely used raw materials in the advertising industry.

Advertising manufacturers usually use acrylic to process crystal characters, billboards, nameplates, signage, etc.; wood is more used to process house plates with artistic characteristics for customers. Use the CO2 laser to engrave any text and pattern on the wood surface, and customize the characteristic display board according to the user's needs. This kind of artistic billboard is very popular among customers.

Double head CO2 laser cutting machine

The double-head CO2 laser cutting machine is based on the ordinary laser cutting machine, adding a CO2 laser tube and a laser cutting head. There are two types of this machine, one is a CNC laser machine that is all used for cutting and engraving non-metallic materials; the other is a multifunctional CNC laser machine for processing metal and non-metal.

The biggest advantage of ordinary double-head laser cutting and engraving machine is that it can improve the production efficiency of the enterprise and produce more workpieces in a short time. Metal and non-metal laser cutting machines have added the function of machine cutting metal, making CO2 laser cutting machines have a wider range of applications. For example, for advertising companies that need to process metal signs, this hybrid laser cutting machine is more suitable.

CO2 laser cutting machine with automatic feeding device

The CO2 laser cutting machine with automatic feeding device is a CNC laser cutting equipment professionally used for fabric processing. It adopts crawler workbench and negative pressure absorption conveyor, which can ensure that the cloth remains flat all the time during cutting. This laser cutting machine is also applicable in a wide range of fields, such as curtain manufacturing, garment processing, sofa covers, bed sheets and other fabric processing enterprises.

The above three models are the most commonly used CO2 laser cutting and engraving machines for small businesses. They are so cheap that even small businesses can afford them.

CO2 laser cutting machine has many advantages such as high engraving precision, smooth cutting edge, and can process any shape, and is widely used. If you are planning to purchase an affordable non-metallic material CNC machining equipment, contact us and you will get professional purchasing advice.