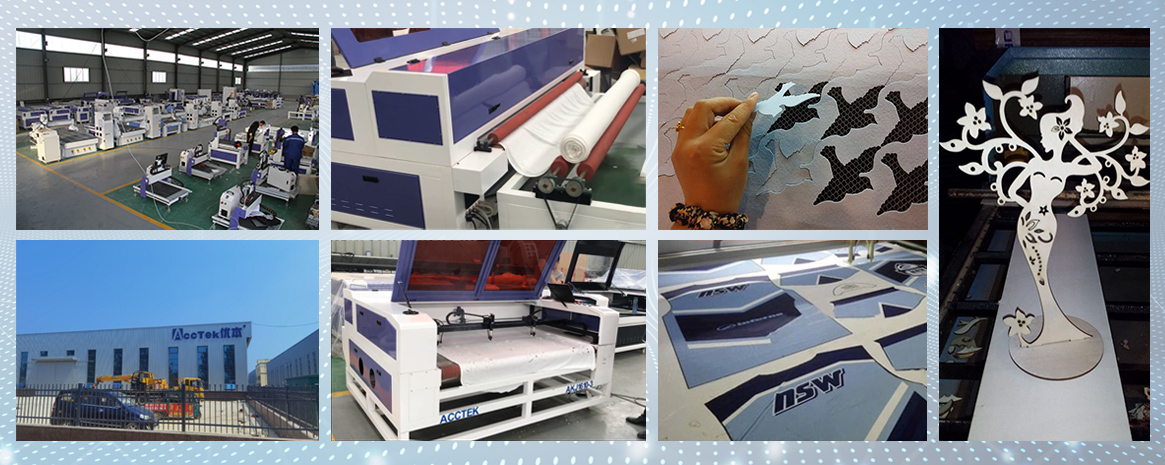

Clothing, curtains, pillowcases, seat covers and other common fabric products in life have unique designs. All these exquisite patterns are completed with the help of a

laser cutting and engraving machine. In addition to being specialized in fabrics and textiles, the CO2 laser machine can also cut and engrave patterns on the leather used to make bags, belts, shoes and other items.

ACCTEK has a laser cloth cutting machine with automatic feeding device, which is widely used in the production of cotton, polyester, nylon, silk and leather fabrics. The CO2 laser machine can perform high-precision engraving and cutting of the fabric without contact with the material, ensuring that the fabric has no burrs or wear during processing. Next we will introduce why the laser fabric cutting machine can create wonderful and unique works for your textile project or leather project.

The fabric laser cutting machine produced by ACCTEK can ensure the safety of material processing. The laser head will not directly contact the material, so it will not cause cutting accidents due to sharp tools like traditional cutting equipment. And it reduces the possibility of material deformation, resulting in a perfect cutting edge. The CO2 laser machine can effectively cut single or multilayer fabric materials.

Manual cutting with traditional tools is tedious and time-consuming. Imagine if you are in the production workshop of a textile manufacturing company, the cutting speed of workers will be much lower than that of a CO2 laser. With a laser cutting and engraving machine, the work will be completed faster and the workpiece quality will be higher. Choosing laser cutting technology will not only increase the output of the workshop, but also reduce labor costs, which will be more conducive to the development of the enterprise.

The laser cutting and engraving machine does not require any additional tools to create patterns on delicate fabrics and textiles. The machine's control system will automatically start the engraving and cutting of patterns according to your design. The whole process is fast and accurate.

Laser cutting technology minimizes errors and defects in the processing of fabrics and leather. As long as your programming is correct, the CO2 laser machine will guarantee the same cut every time. The fabric processed by laser machine has no discoloration, deformation or uneven edges in any form.

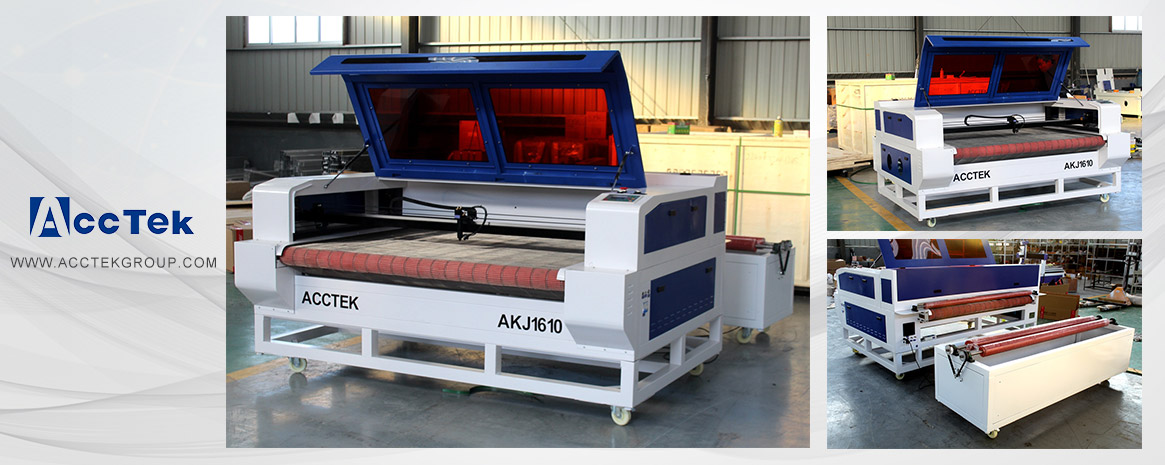

The fabric CO2 laser machine produced by ACCTEK has an automatic roller table and feeding device. It adopts crawler working table and negative pressure absorb conveyor, make sure the smooth of materials when cutting. Working with auto feeding system, can meet the requirements for continuous and automatic batch cutting.

2021 Best Fabric CO2 Laser Cutting Machine Features

1. New-style high-efficiency Reci CO2 laser tube is adopted. Compared with the laser tube of the same level, slim and stable beam, high quality spot. Usage age is more than 10000 hours. Each

CO2 laser cutting machine of ACCTEK is equipped installation of reinforcement stings, the laser tube is not easy to collide and cause damage when moving the machine.

2. Red dot position system is added in standard configuration, contributing to simple and precise working position. Cutting head always follows the material to keep the cutting point location unchanged.

3. Advanced Ruida control system, with professional motion control chip, has the function of consecutively high-speed curve cutting and the shortest path selection, which largely improves your working efficiency. Ruida control system supports USB cable controlled by computer and and also offline control system by just a U disk. The operation is more convenient and faster.

4. The CO2 fabric laser cutter machine is equipped with square tube framework, with more than 40% higher fuselage strength than iron sheet structure. This design prevents the laser machine from quivering, resonance and distortion during long term work.

5. Taiwan HIWIN square linear guide rail installed on X Y axis, with good bearing capacity. It makes sure the works stably and precisely.

Application of fabric laser cutting and engraving machine

Leather materials: genuine leather, artificial leather, soft leather, decorative leather, etc.;

Textile materials: pure cotton, real silk, various chemical fibers, felt, denim, etc.

Many workshops simply add

CO2 laser cutting machines to improve production efficiency in order to gain a larger market. If your business is engaged in the production of clothing, shoes or bags, then it is time to buy a laser cutting and engraving machine for your shop.