With the development of laser technology, manual focusing will gradually be eliminated. The auto-focus function has the advantages of high performance and high-speed cutting and has been steadily developed. The auto-focus function is widely used in

fiber laser cutting and

co2 laser cutting.

Two ways to complete auto focus

The first method is that the focal length of the focusing lens cannot be changed, so by changing the focal length that is impractical for focusing. If you change the focus position of the mirror, you must change the focus position accordingly: when the focus lens drops, the focus decreases, and when the focus lens increases, the focus increases. This is a way of focusing. Using the focus lens drive motor for upward and downward movement, automatic focusing is achieved.

Another method is auto-focusing: before the light beam enters the focusing lens, the variable curvature lens group (or adjustable mirror), by changing the curvature of the mirror, changing the divergence angle of the reflected light beam, and changing the focus position. With the auto-focus function, the CNC machine tool will quickly and automatically adjust the focus to the appropriate position when processing workpieces of different materials and different thicknesses. This can improve the processing efficiency of a significant high-speed

laser cutting machine, and the board perforation time will be greatly reduced.

1) Quality guaranteed laser beam

The smaller the focused spot, the finer the cutting line, the higher the productivity, the better the quality and the processing effect.

2) Fast cutting speed

3) High stability

Using the world's top imported fiber laser, the performance is stable, and the life of key components is as long as 100,000 hours.

4) High electro-optical conversion efficiency

Fiber laser cutting machine is 3 times higher than CO2 laser electro-optical conversion efficiency, energy saving and environmental protection.

5) Low cost

6) Low maintenance cost

The non-working gas laser only needs optical fiber transmission and no reflective lens is needed, which can save a lot of maintenance costs.

7) Convenient operation and maintenance

Optical transmission, no need to adjust the optical path.

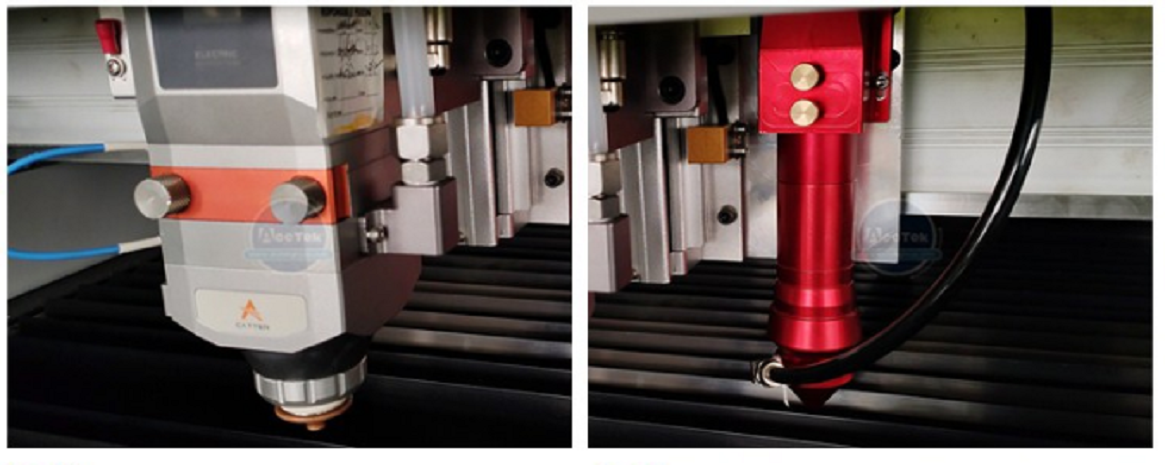

8) Double-head cutting machine

The fiber laser cutting head is suitable for metal materials, and the

co2 laser cutting head is suitable for non-metal materials.