The application of

fiber laser cutting machines in metal projects is becoming more and more popular. If you plan to invest in a fiber laser cutting machine, then you must be very concerned about its application fields in order to better develop your own laser business. ACCTEK, as a supplier of fiber laser cutting machines, summarizes the main application areas of fiber laser cutter for your reference.

Decoration industry

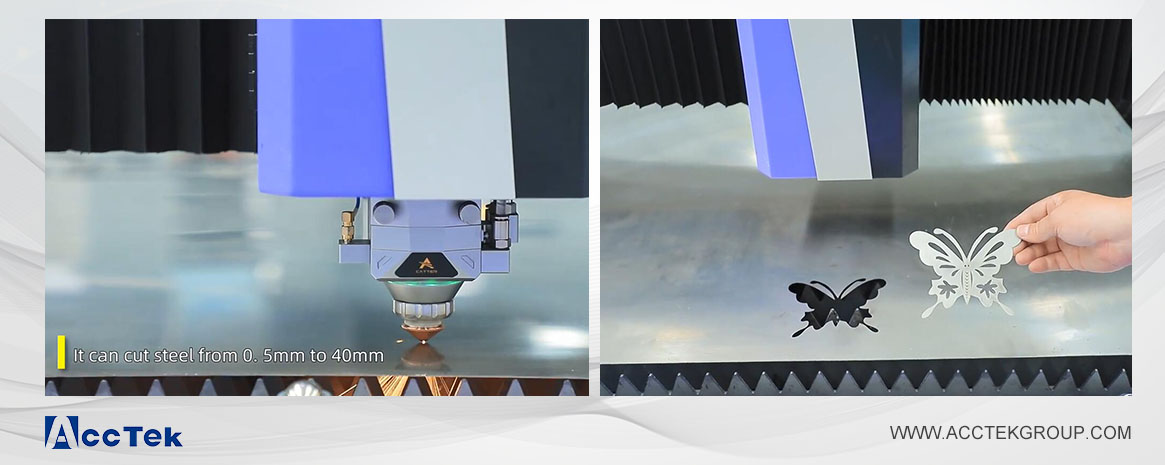

Fiber laser cutting machine has fast cutting speed and flexible cutting. The efficient fiber laser cutting system can cut many complicated patterns according to the design. It is very easy to realize the customization of metal workpieces, and the cutting effect has won the favor of decoration companies.

Automobile industry

Many metal parts of automobiles, such as car doors, automobile exhaust pipes, brakes, etc., can be precisely processed by fiber laser metal cutting machines. Compared with traditional cutting methods, fiber laser cutting ensures excellent accuracy and work efficiency, and greatly improves the production efficiency and safety of auto parts.

Kitchenware industry

Because stainless steel has excellent corrosion resistance and durability, stainless steel kitchen utensils are more and more widely used in our lives, and kitchen-related products have a broad market in the world. The use of fiber laser cutting machine can accurately cut and perforate stainless steel plates and tubes to produce qualified metal kitchen utensils. The stainless steel laser cutting machine has high speed, high precision, good effect and smooth cutting surface, which can realize customized and personalized product development.

Advertising industry

Due to the large number of customized products in the advertising industry, traditional processing methods are obviously inefficient, and fiber laser cutting machines are very suitable for this industry. The

metal laser cutting machine can cut and hollow out various complex graphics, with good cutting quality, high efficiency and high flexibility, and is especially suitable for the production of metal signs.

Machinery Industry

Whether it is agricultural machinery or construction machinery, the production of their fuselage and parts requires metal cutting laser machine processing. What are the benefits of using a fiber laser cutting machine to process these sheet metals? Since laser cutting is a non-contact processing method, it will not cause extrusion and deformation of metal materials. And the processing speed is fast, no molds or tools are needed, which greatly shortens the production preparation time.

Fitness Equipment

With the development of living standards, people pay more and more attention to physical health. Whether it is a well-equipped gymnasium or a fitness plaza in a park, a large number of metal pipes are needed to make fitness equipment. The metal tube sheet fiber laser cutting machine is more and more popular in the cutting and drilling of metal tubes. The fiber laser tube cutting machine can cut standard or heterogeneous pipes such as round pipes, square pipes, elliptical pipes, etc. It adopts CNC controlled automatic working way, which significantly improves the production efficiency of fitness equipment and shortens the production cycle.

The above are the main application areas of fiber laser cutting machine. Of course, its applications are more than that. It is also widely used in various metal project fields such as household appliance industry, lighting industry, ship industry, construction industry and so on.

Fiber laser cutting machines have irreplaceable functions and advantages in the field of sheet metal cutting, which can bring more benefits to metal manufacturers.

You can choose the appropriate power and configuration according to the thickness and size of the material to be cut. If you need professional advice, you can consult online at any time. Or send your question to our email: sales@acctekgroup.com, we will provide you with a solution.