Since the widespread promotion of CNC machine tools,

woodworking CNC routers have become the fastest growing and most widely used CNC engraving equipment. This has a lot to do with its own advantages and social development needs. Woodworking CNC router is a very popular fine engraving equipment in the market at present, and it is suitable for mass production of products, which can largely free the factory from dependence on labor.

As a professional CNC router manufacturer, ACCTEK has provided various types of woodworking CNC routers to more than one hundred countries. Here, I will show you some of the most popular woodworking CNC engraving equipment. If you are working on a woodworking project, or ready to start a woodworking plan, understanding them will bring more help to your production.

Heavy duty 3 axis CNC wood router

The most common sizes of heavy-duty 3 axis CNC wood routers are 4×8ft and 5×10ft, which are our AKM1325 and AKM1530 models. These two CNC machine tools are the most commonly used CNC engraving equipment in the furniture manufacturing industry. The size of the workbench meets most specifications for the processing and production of materials such as door panels, cabinet panels, and dining table panels. The CNC router spindle adopts the well-known Chinese brand HQD that has obtained CE certification. The power range is 1.5KW-6.0KW, which is often related to the thickness of the wood board and the cutting speed you need. As long as the combination is reasonable, you can easily complete wood carving and cutting.

In the picture you can see that the rear of the machine is equipped with feeding auxiliary wheels, which are designed for processing heavy-duty plates or large-size plates. Machine operators can use auxiliary wheels to feed materials, which can not only reduce work intensity, but also improve work efficiency. In addition, an alarm light is installed above the CNC router control cabinet, and users can monitor in real time whether the machine is running normally through the color of the alarm light.

ATC CNC wood router with auto tool changer

The 3 axis CNC router we mentioned above is suitable for small-scale production enterprises. If you are a large-scale production workshop and need to mass-produce woodworking projects, then the

ATC CNC router with auto tool changer is your best choice. Among them, AKM1325C and AKM1530C are still our two very popular models. These two woodworking CNC engraving machines are equipped with an automatic tool change magazine, which is loaded with 8 different tools. It only takes a few seconds to complete the automatic tool change during the workpiece processing without stopping the machine, which reduces the waste of non-production time. ATC CNC router has great advantages for projects that need to engrave different processes on the same plate. The tool can be replaced flexibly, and personalized patterns can be created in a short time, increasing the uniqueness and customization of woodworking projects.

Rotary axis CNC wood router

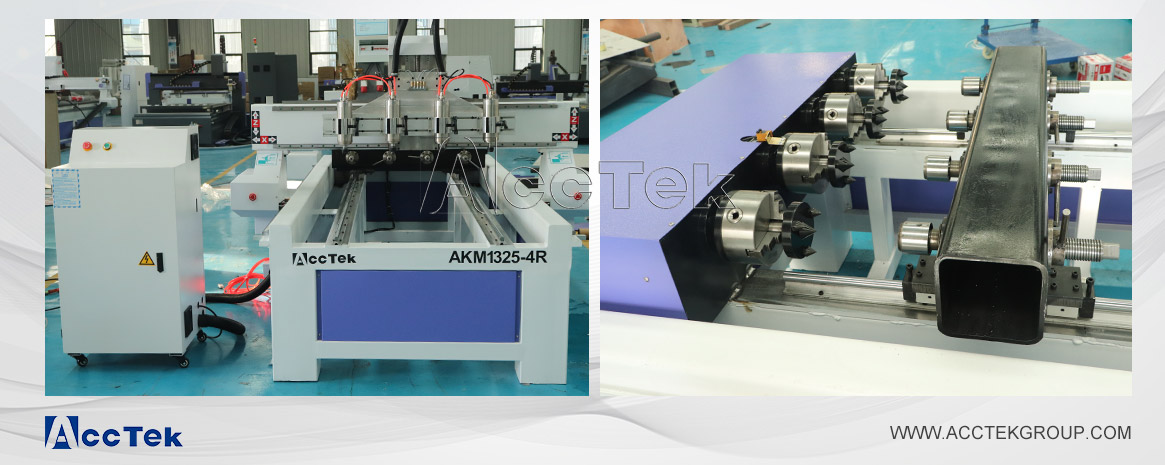

The rotary axis CNC wood router is a kind of woodworking engraving equipment specially used for cylindrical material processing. It consists of four CNC router spindles and four rotary axis devices. Each of its rotary axis units has a thimble and a chuck for holding cylindrical materials to complete the engraving of the workpiece. This structure is very firm, which can effectively ensure that the material will not loosen during the operation of the machine, so that the carved workpiece has higher precision and quality. The chuck has additional trays on the collets to hold large diameter cylindrical materials.

The rotary axis CNC wood router you see is just one type of cylindrical material processing, and you can customize the machine according to your actual needs. The number of spindles and rotation axes can be selected by yourself, and you can also combine plane engraving and cylinder engraving to customize a multifunctional CNC woodworking machine tool.

4 Axis CNC wood router

4 Axis CNC wood router is a high-end CNC engraving equipment applied to 3D projects, it can carve various 3D projects in regular, irregular, symmetrical and asymmetrical. Compared with the rotary axis CNC router, the swing head 4 axis CNC router provides you with greater flexibility, its spindle tool can engrave or mill a cylindrical blank at any angle from 0 degrees to 180 degrees.

In addition to the processing of cylindrical materials, 4 axis woodworking CNC routers are also widely used in various woodworking projects such as ship models, car models, and figure sculptures. If you need to process complex workpieces and special-shaped workpieces, this 4 axis CNC router can meet your diverse processing needs.

The woodworking

4 axis CNC router can provide the best cutting speed and the angle of chip evacuation, and produce nearly perfect contours and smooth surfaces through gradual rotary processing, so that users can obtain high-quality 3D workpieces.

The four CNC router machines introduced above represent different types of woodworking CNC tools. In the face of different processing needs, choosing the right machine can help enterprises obtain the maximum profit within the optimal budget. If you don't know how to choose, communicate with us online, ACCTEK staff will provide you with professional advice and help, so that you can start your woodworking project faster.