Speaking of

five-axis engraving machine, everyone must have heard of it. What is a five-axis engraving machine? The five-axis engraving machine is composed of five axes, XYZ AB, to form a five-axis. At present, the application of five-axis engraving machine is very common. The industries involved in processing include gift industry, advertising industry, seal industry, wood processing industry, construction industry, art model industry, mechanical processing, tooling and molds.

1. Configuration is very important

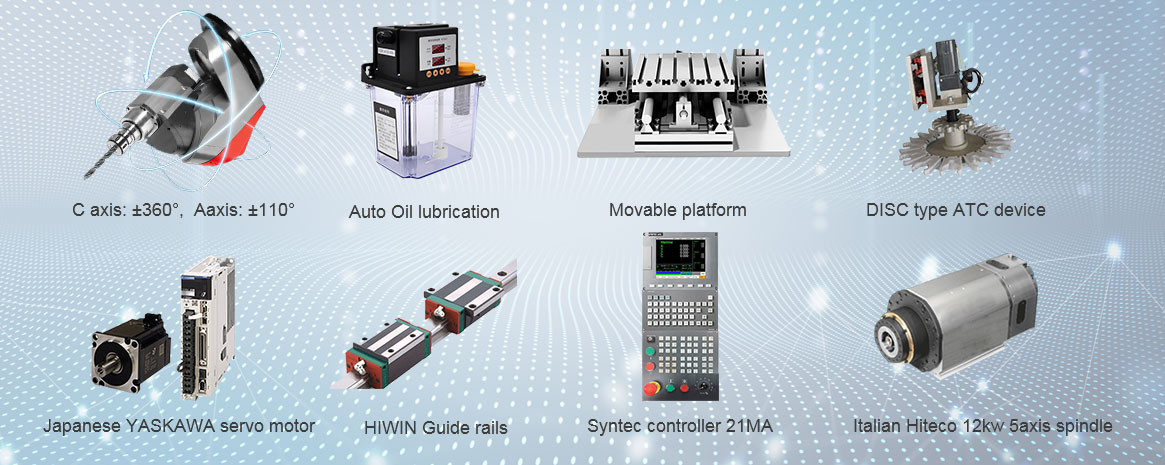

The main configuration of AKM1325

Disc type automatic tool changer

8pcs carousel automatic tool changer, HSK63F tool holder.

The tool magazine is fixed on the side of the gantry, and is always on the same horizontal line as the spindle. The machine tool does not need to change tools manually when working, and the efficiency is greatly improved. More tool replacements are available.

Italy Hiteco 12kw 5-axis spindle

With strong cutting ability and low noise, the machine can work for a long time.

Xinda Controller 21MA

Professional well-known brand of five-axis machine tool series.

Five-axis linkage, with RTCP function (true five-axis interpolation), suitable for large-scale 3D surface processing modeling. CNC system resolution: ±0.001mm.

Silver rail

The guide rail cooperates with the sliding block to drive the machine to move. Stable operation, high-speed silent, high abrasion resistance, and good carrying capacity.

Yaskawa Servo Motor

Yaskawa servo motors have the highest amplifier response in the industry, which greatly shortens the setting time, realizes high-speed acceleration and deceleration, and responds quickly. It has the function of resonance suppression to ensure the smooth operation of the machine at high speed. Strong anti-interference ability and strong anti-overload ability.

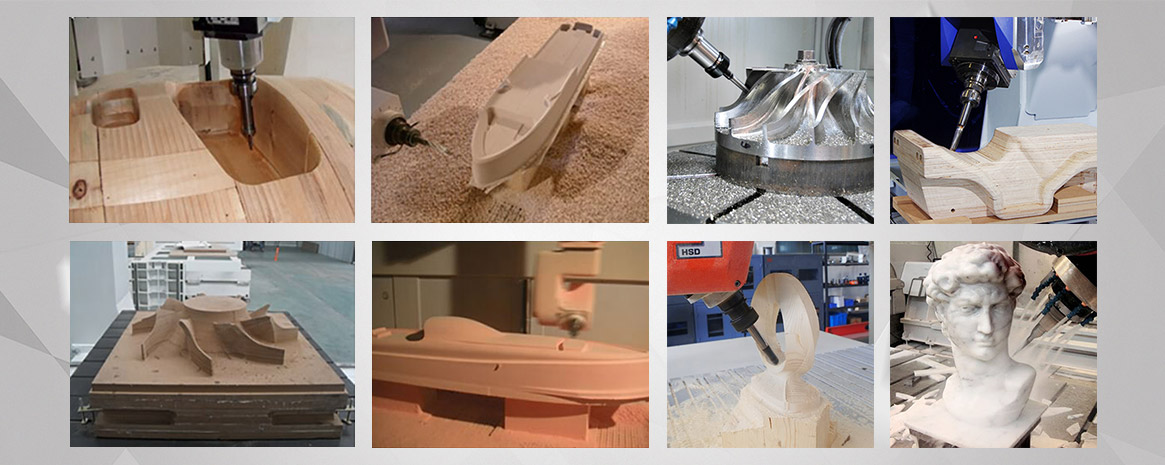

2. Wide range of applications

The engraving range of the

five-axis engraving machine is very wide, which can truly reduce labor costs, improve the efficiency of processed products, and realize a fully automatic intelligent engraving system. The five-axis engraving machine is used in wooden molds, foams, blister molds, casting molds, etc. The field can also be used. At the same time, the products are also indispensable and important processing equipment in the fields of trimming, sawing, drilling, grinding and polishing. It is the first option for enterprises to complete automatic processing and realize profit and consumption reduction.

1. Relief carving and 3D carving; carving of cylindrical objects.

2. Mould industry: a variety of wooden models such as wooden ship models, car models, and wooden model aviation.

3. Wood furniture industry: wave board, fine grain, antique furniture, wooden doors, screens, craft window sashes, interior doors, sofa legs, etc.

4. Foam industry: 2D and 3D size processing, engraving and cutting can be carried out on any kind of foam. Processing effects: engraving, cutting, milling, drilling, embossing, shadows, etc.

5. Carving various large non-metallic molds, especially suitable for any kind of foam (EPS) mold, wooden boat mold, wooden mold aviation and other wooden mold 3D processing.

3. Strong functional performance

1) Low business expenses:

Investing in a five-axis engraving machine can help reduce operating costs, provide better material yields, faster part cycle times, and prevent cutting errors and wasting expensive materials.

2) Short delivery time:

The five-axis engraving machine provides faster cutting cycle time and accurate information. Manufacturers will know exactly how many minutes it takes to run a job on a five-axis engraving machine, which will enable them to better plan and calculate operating costs.

3) Better edge processing:

The five-axis engraving machine will accurately follow the geometry of the programmed part. Smooth, consistent movement will produce parts and provide a sharp, clean edge finish.

4) Better material yield:

The use of CNC parts can be nested together to maximize material utilization. This reduces the amount of material used, thereby reducing indirect costs.

5) More accurate operation:

The operation of the CNC engraving machine is repeatable. This precision ensures that the geometry of the part and the product are perfect for every cut.

6) Greater flexibility:

The only limitation of the five-axis engraving machine is the user's imagination. This new ability to create anything provides business owners with new opportunities to replace traditional methods of processing products.