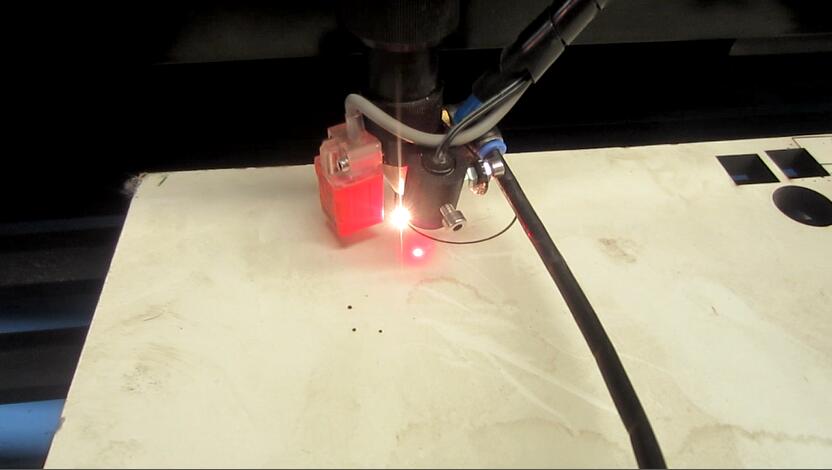

Laser wood cutting is generally the use of CO2 laser, its wavelength is 10.6 m.However, the photoelectric conversion rate of CO2 laser is low (only 5% ~ 10%), and the energy consumption is relatively large.The laser needs frequent ventilation and the maintenance cost is high.External optical path is complex and difficult to install, debug and maintain.Therefore, CO2 laser has great limitation in the actual industrial production and application, and its application is becoming less and less.

The common optical fiber laser (wavelength 1 m) cutting sheet metal has become very common, so can this optical fiber laser be used to cut wood?If it's an erbium-doped fiber laser with a wavelength of 1 m, the answer is: It's hard.This is because the absorption of wood to 1 m wavelength laser is relatively low, difficult to form seam.

A new type of "thulium" element fiber laser should be selected. After "thulium" element is doped inside the fiber;The wavelength of the laser is 2 m.Wood, especially the moisture in wood, absorbs more water than the usual 1 m wavelength of the laser.

● High quality AKJ1530 CO2 laser cutting machine

● ATC CNC Router with a horizontal spindle

● High quality AK30F fiber laser marking machine

● High quality AK20F laser fiber marking machine

● Big news: we're building a new factory

● Polish customer purchased AKM1530 high quality CNC engraving machine

● Heavy duty ATC CNC router with horizontal spindle AKM2030C

● Acctek exhibition footprint

● Cost-effective fiber laser cutting machine AKJ1530F1

● ACCTEK cnc router wishes everyone a Merry Christmas

Get a Free Quote Now!

Useful Link

Recommend Machine

Big discount

Headquarters: 3-1007, Minghu Plaza, No. 777 Minghu West Street,Jinan City / Branch: A2-1-1802, Hanyu Jingu, High-tech Zone, Jinan City

Factory: No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province

Copyright © Jinan AccTek Machinery Co.,Ltd