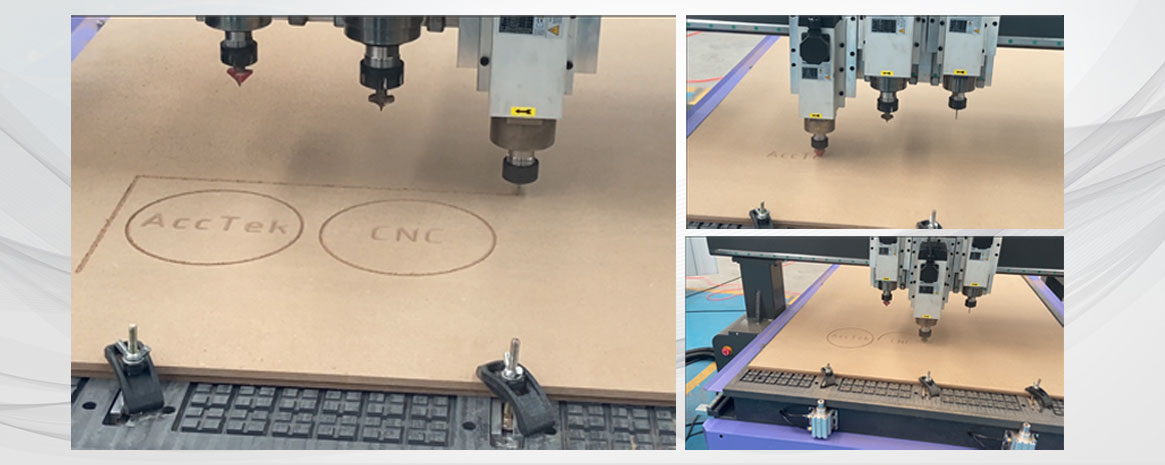

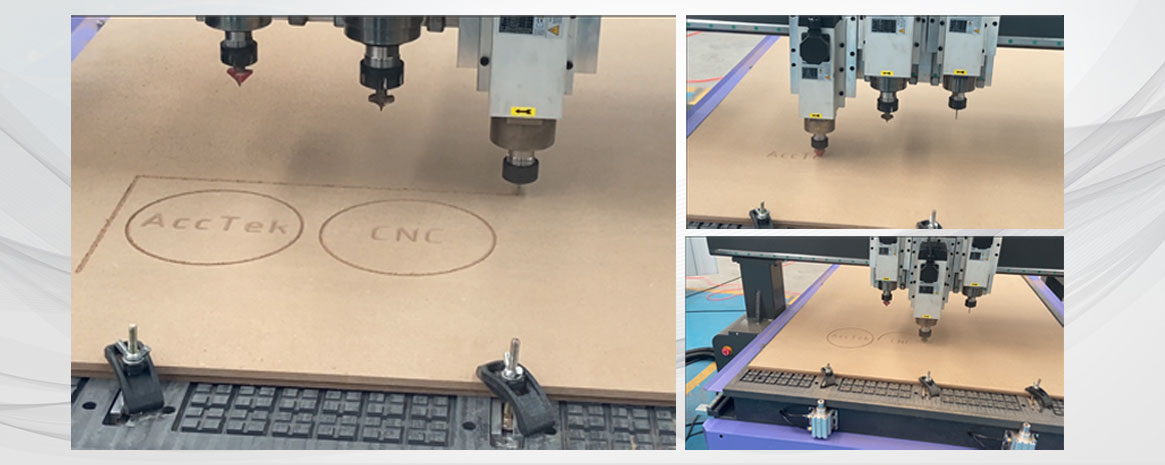

ACCTEK engineer is testing the

three-head CNC router AKM1325-3, which will be sent to Australian user. This three-head CNC engraving machine is also called ATC cnc router machine because its three spindles work independently. After the first spindle tool completes the first process, the second spindle tool will run the next process. Therefore, it is also known as a three-process CNC router, which is very suitable for processing different patterns on the same plate. It does not need to stop the machine for manual tool change, which greatly improves the production efficiency of the workshop.

Our Australian user is a furniture manufacturer. This three-head woodworking engraving machine can process cabinets and wardrobes for him, and complete the engraving of patterns on the panels and the cutting of panels. The following are the characteristics and configuration of this CNC machine. If your shop also needs to complete a complex engraving path, you can use it as a reference.

The working area of the three-head CNC router AKM1325-3 is 1300×2500×250mm, and each spindle tool can reach the maximum processing area. The spindle is selected from a well-known Chinese brand HQD that has obtained CE certification. This Australian customer chose an air-cooled spindle. According to the engraving and cutting needs, he chose two 3.5KW spindles and one 6.0KW spindle. Of course, we will recommend the appropriate spindle type and power for you according to your working environment and processing needs.

The customized

woodworking engraving machine AKM1325-3 is configured with LNC5800 4-axis. Compared with the Mach 3 controller, it has a control panel and is more convenient to operate. Equipped with easy servo driver and stepper motor, it has strong power and reliable performance, ensuring the machine runs at high speed and stability. This machine uses Fuling inverter. This inverter has stable performance, rich combination of functions, high-performance vector control technology, low-speed and high-torque output, good dynamic characteristics and super overload capacity.

Because the machine is mostly used for wood carving and cutting, a lot of wood chips will be produced during the processing of the board, so we recommend a double bags dust collector for our customers. When the CNC router is working, the dust-proof brush on the spindle to control all the sawdust residues in a small range, and then debris is sucked into the vacuum cleaner. It not only ensures the cleanliness of the working environment, but also benefits the health of the staff.

In addition to processing cabinets and wardrobes, Australian users also need to process cylindrical materials such as Roman pillars and railings, so a rotary axis device is added. The axis has a diameter of 200mm and a length of 2000mm, placed on the side of the machine. If you only need to process smaller cylindrical materials, you can choose a small rotary axis, which can be directly placed on the machine table for use, which is more convenient.

The development of the furniture industry is inseparable from the application and progress of

CNC Router machines. ACCTEK will customize a multi-functional engraving machine according to the needs of each user, allowing you to purchase the most suitable equipment at the most favorable price.

Whether you are in the woodworking industry, advertising industry or other engraving industry, as long as you have engraving needs, you can consult with us online. Our staff will provide you with the best purchase plan.