Auto tool change CNC router machine is a more advanced CNC engraving machine equipment, and it is also the development trend of CNC machine. It has an independent tool magazine, which can automatically change the required tools during the processing of the workpiece without stopping work. When engraving complex patterns, you can choose different tools, which greatly speeds up work efficiency and improves product quality.

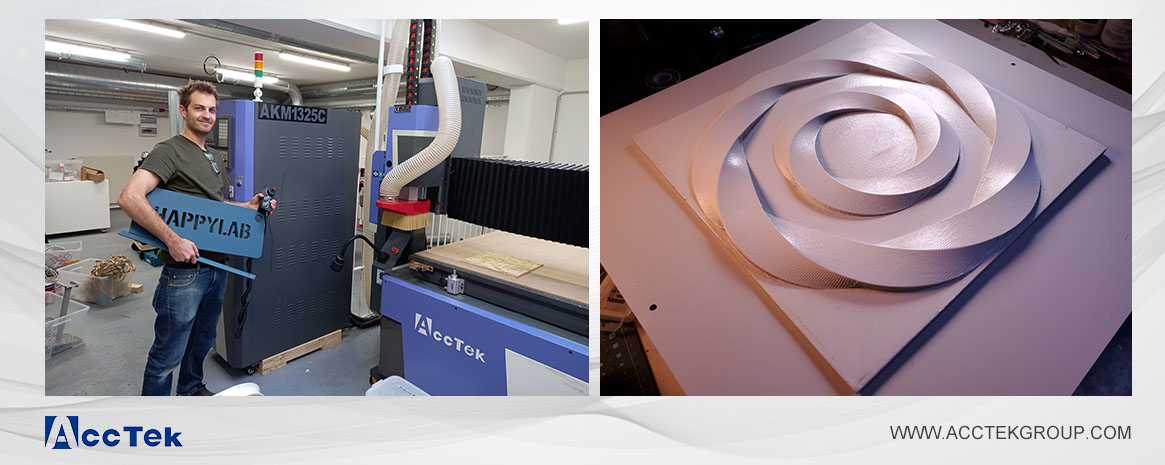

ACCTEK ATC CNC router AKM1325C is the first choice for large workshops and enterprises with a large workload. The ATC CNC router shown in this post is prepared for American customer, and all accessories use internationally renowned brands to ensure that the machine has stable performance and longer service life. The following is an introduction to the features and configuration of this CNC engraving machine. If you plan to upgrade the CNC engraving equipment for your workshop, it will be your first choice.

The working area of this CNC router AKM1325C is 1300×2500mm. This machine is equipped with Taiwan Syntec 60W-E control system, which has good stability, powerful functions. The operating software is simple and easy to learn, the man-machine operation is friendly. Professionally applied to high-end cnc router machines, the anti-interference ability and control accuracy of the control system are superior to other types.

The spindle is selected from a well-known Chinese brand HQD that has obtained CE certification. The 9.0KW air cooling spindle has strong power and extremely high reliability. This spindle has high precision, long life, low noise and low vibration. The axial stability of the spindle is good, and the workpiece machining accuracy is high. Very suitable for engraving processing of fine patterns. It can ensure that accurate patterns are obtained during the material engraving process.

The

ATC CNC router AKM1325C is equipped with a linear auto tool changer with 8 tools. Don’t need to change tools manually when machine works, which saves a lot of time and greatly improves the efficiency of material processing. It is very suitable for complex and large-scale engraving processing.

This ATC CNC router uses a T-slot and vacuum combined worktable, which is more conducive to processing different materials and is very helpful for improving work efficiency. The T-slot table can use clamps to fix small materials and save the power of the vacuum pump; the vacuum table can use vacuum adsorption to fix large materials, which is more convenient, simple and efficient to process. The vacuum table is divided into 4 areas according to user needs, and each area is controlled by a switch. It can be used flexibly according to the size of the processed material.

ACCTEK ATC CNC router is equipped with a 3.0KW double-bag dust collector for customers, with an independent bracket, which is more convenient and beautiful to install. It not only ensures the cleanliness of the working environment, but also benefits the health of the staff. If you need to process cylindrical materials, you only need to add a rotary axis device. Customized CNC engraving machine can provide you with more functions.

ATC CNC router machine is widely used in wood carving and cutting, especially in the furniture industry and handicraft processing industry. Its processing efficiency and processing precision bring a larger market and more business to the enterprise. If your business is in a stage of rapid development, choosing an

ATC CNC engraving machine for your shop will be an important step.