For the metal processing industry, choosing a suitable metal laser cutting machine is very important. It can not only save labor costs, improve work efficiency, but also effectively improve product quality, which is very important for the development of the company. Introduce a small size precision fiber laser cutting machine AKJ1390F, mainly for alloy materials, lighting, hardware products, metal kitchenware, metal crafts processing and many other industries. The following is the introduction of AKJ1390F. If your workshop also needs to process metal, I hope it can help you expand your production scale and gain more customers' love.

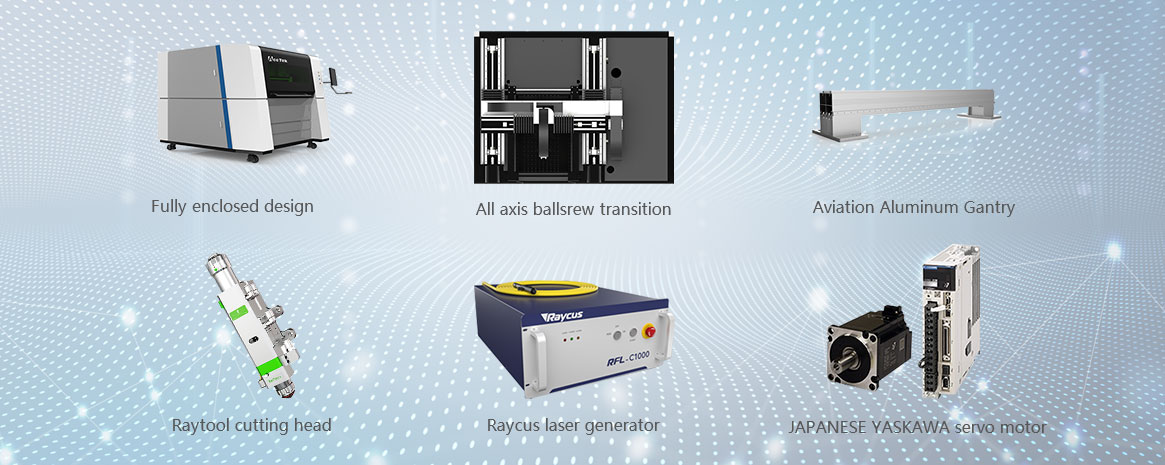

The configuration of the

fiber cutting machine AKJ1390F:

Fully enclosed design

The window adopts an European CE standard laser protective glass,ensure the operator's safty and avoid the somke.

Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries.

Raycus laser generator

Raycus has an efficient and professional R&D and production team. The single module CW fiber laser series not only can meet diversified demands of customers to the greatest extent,but also provide personal customization service. Now laser output connector is QBH,with multiple control modes.

Swiss Raytools brand auto-focusing cutting head

The Raytools Laser Cutting Heads are released based on Switzerland RAYTOOLS, which are suitable for medium and high power fiber lasers in industrial applications.

1. It adopts imported closed-loop motor, high-speed perforation and cutting of various material thickness, and the repeating precision is 0.01mm.

2. Automatically find the best focal length instead of mamual focusing, the adjustment range is -10-+10mm.The focusing speed reaches 400mm/s, more efficient.

3. IP65 dust-proof design, fully protect internal optical components and extend service life.

4. Buit-in collimating lens focusing lens double water cooling structure, reducing the temperature of the cutting head and prolonging the service life of the cutting head.

HIWIN Guide rails

Rail works with slider, drive the machine move. Smooth running, high-speed silent, high abrasion resistance, and good load-carrying capacity.

Japanese Yaskawa Servo Motor

1. It has the highest amplifier responsiveness in the same industry, which greatly shortens the setting time, realizes acceleration and deceletation at high speed, and has fast response.

2. Low heat, low noise, high speed and high precision,

3. Strong anti-interference ability and strong anti-overload capability.

4. There is automatic adjustment mode, if the effect is not good, it can be adjusted more conveniently.

All axis ballsrew transition

To prevent the cutting line deformation caused by the Y-axis screw bending, the Y-axis on both sides have been equipped two rails guide and double ball drive screw design to ensure the straightness and arc degree when with high-speed cutting is in operation.

In order to adapt to market demand, laser equipment is developing in a more automated and intelligent direction. Whether it is a more sophisticated ultrafast laser or a higher power 10,000-watt fiber laser cutting machine, various new concepts are emerging in an endless stream. In the process of purchasing a laser cutting machine, you must choose the right product according to your actual production needs. There is a saying in China that only choose the right one, not the expensive one. It is the most reasonable and effective solution to not only save one's own cost, but also ensure high-efficiency and high-quality production needs.

If you are interested in our metal laser cutting machine, or have any question about the

fiber laser cutter machine. You can consult online at any time, and our professionals will reply you in time and provide effective solutions. I hope it helps you.