Laser cleaning machine is a hot-selling machine of ACCTEK Machinery. As a supplement and extension of traditional cleaning methods, laser cleaning technology has been welcomed by various industries since its inception. Laser cleaning machine is a new generation of high-tech surface cleaning laser system. It adopts advanced laser source and control system to meet the requirements of metal surface cleaning process.

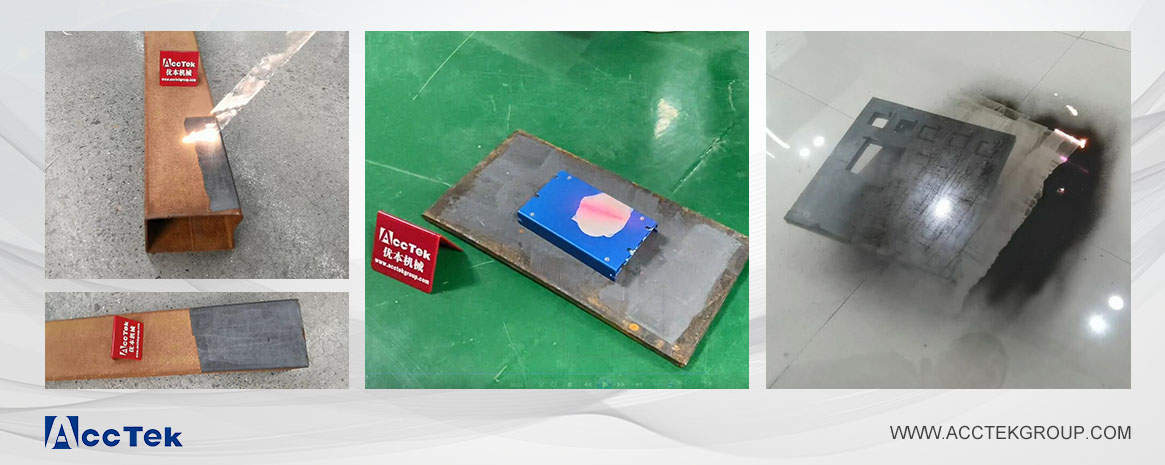

ACCTEK engineer are testing a 1000W laser cleaning machine, its performance is very stable, this is a cleaning equipment for Russian user. The following is an introduction to the configuration and features of this machine. If your workshop needs a cleaning machine, you can use it as a reference for purchase.

This laser cleaner AKQ-1000 is equipped with 1000W Raycus laser source. The laser has higher electro-optical conversion efficiency, higher and more stable optical quality. The surface of metal materials is cleaned by laser irradiation. The entire cleaning process has no grinding, non-contact, no thermal effect, no mechanical force on the material to be cleaned, no damage to the surface of the object, and no damage to the substrate.

The laser cleaning head adopts Hanwei handheld cleaning gun, which can flexibly deal with various objects and angles. The connection cable between the laser head and the machine is up to 10 meters long, and the material can be cleaned in a larger area without moving the machine. If your workshop area is large, you can customize the cable length, there are 15 meters and 20 meters to choose from.

The

fiber laser cleaning machine is equipped with a Hanwei controller. It has multiple light emission modes and strong compatibility. 32 sets of process parameters can be saved in the process library. Each mode corresponds to a different parameter setting, and the cleaning parameters of the corresponding material can be saved. When you clean the same material, you can directly select the corresponding mode without setting the parameters again.

The laser cleaner AKQ-1000 is equipped with a Hanli chiller. This chiller is specially developed for fiber laser equipment with excellent heat dissipation effect. Stable and reliable performance, low failure rate, high efficiency and energy saving.

Laser cleaning can remove different types of contaminants on the surface of various materials, including rust, paint, cement, oil, dust, etc. The whole cleaning process is safe and efficient, and the cleaning effect is very ideal. ACCTEK performs cleaning experiments on a variety of contaminants on the surface of metal materials, and the comparison before and after cleaning is very obvious.

Laser cleaning machines are widely used in various industries, such as auto parts, rubber molds, high-end machine tools, rails, environmental protection equipment and other industries. The entire cleaning process does not require chemicals, will not pollute the environment, nor will it harm the health of employees, making it more environmentally friendly and safer.

Fiber laser cleaning machine is easy to install, control and realize automation. Although the initial investment is relatively high, it can be used stably for a long time. There are almost no consumables and no special maintenance, so in the long run, operating costs are much lower than traditional cleaning methods. If you want to know whether the laser cleaning machine is suitable for your workshop, you can communicate online.