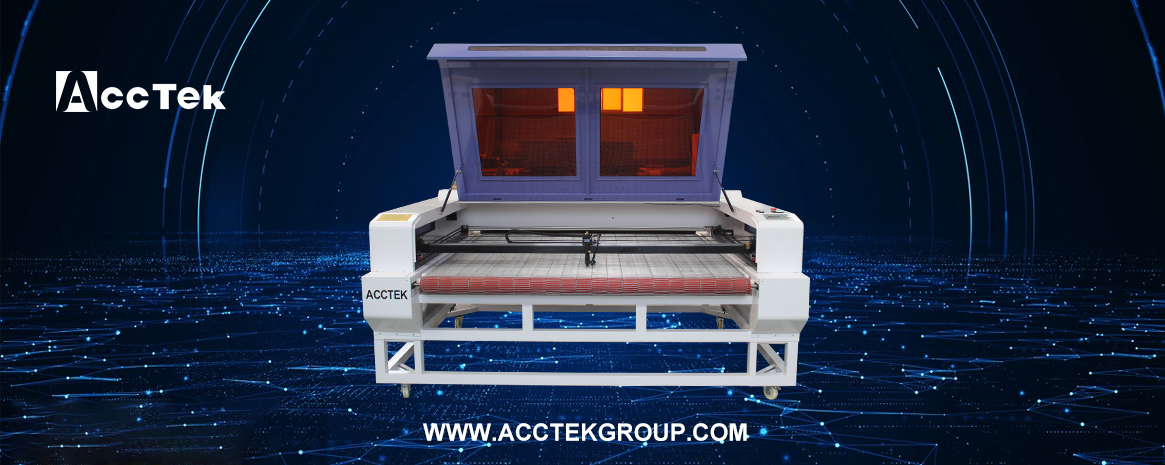

In the clothing production industry, large-scale processing of fabrics requires high-efficiency production equipment. Today ACCTEK introduces an automatic feeding laser cutting machine AKJ1610. This laser cutting machine adopting high speed, high precision stepper motor, automatic feed, automatically capture the border and cutting speed is 2.5 times than of the traditional, which is the best choice of modern high-speed fully automatic large enterprise.

The following are the advantages and configurations of the automatic feeding laser cutting machine. You can choose the right

laser machine for your workshop according to your production needs.

1.Famous brand - Reci 80w laser tube

China famous Brand- Reci Glass Sealed Laser Tube, water cooling way. High stability, longer lifetime up to 10000 hours.

2.Ruida control system with LCD panel

LCD controlling panel support various languages and clear display, more convenient operation. Advanced DSP control system, with professional motion control chip, has the function of consecutively high speed curve cutting and the shortest path selection, which largely improves your working efficiency. USB offline control system makes the operation more convenient and faster.

3.Laser head with red dot location.

As laser light is invisible, red light pointer can realize the exact position of laser beam.

We can see laser moving path with red pointer function because laser beam is in-visible.

4.Taiwan high accuracy Square guide rails

Smooth running, high-speed silent, high abrasion resistance, and good load-carrying capacity. It helps laser head move smoothly, so improve machine engraving cutting precision and speed.

5.Industrial Water Chiller.

China good quality industrial Air-conditional water chiller, have temperature display and alarm

Function, so can avoid over burning, and protects the water circulation from electricity-off.

6.Automatic roller table and feeding device.

This laser cutting machine adopt crawler working table and negative pressure absorb conveyor, make sure the smooth of materials when cutting. Working with auto feeding system, can meet the requirements for continuous and automatic batch cutting.

7.Stepper motor and Leadshine driver.

Acctek cnc laser machine uses high quality stepper motor and drivers, famous brand Leadshine.

These motors require no regular maintenance, reducing any maintenance downtime.

8.Singapore three mirrors and one lens.

1) 45° mirror adjustment set. Three point dimming bolt for easier dimming.

2) Imported Lens, suitable for vanous environments, and has high precision and high speed.

9. The laser cutting machine can install multiple laser heads, improve work efficiency.

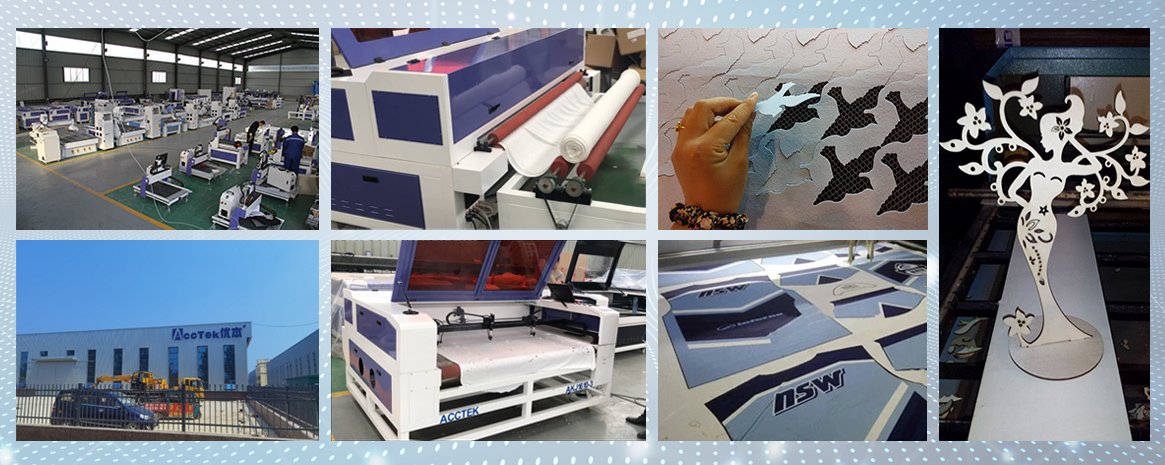

Auto feeding laser cutting machine is applicable to printed brand, electronic panel, mask, textile brand(woven label), cutting after embroidering of embroidery and such multitudinous industrializations application. Specially caters to small batch and much varieties garment fabrics cutting, especially suitable for made-to-measure clothing.

The above is an introduction to the auto feeding laser cutting machine. If you want to buy a suitable cutting equipment, you can leave a message online, and our staff will recommend the most

suitable machine for you according to your cutting needs. I hope it helps you.