The development of the woodworking industry is inseparable from the application and progress of

CNC router machines. With the increasing demand for woodworking engraving, CNC router machines are also gradually developing towards multi-function. This article introduces to you a multi-process CNC router machine - AKM1325R-3, which is also an automatic tool change CNC router machine.

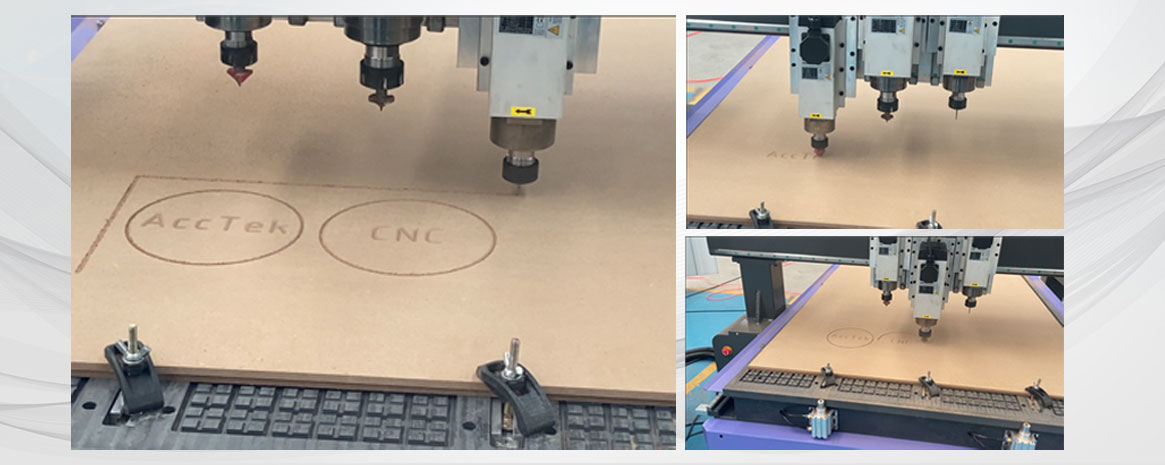

The CNC router machine AKM1325R-3 is equipped with three spindles, each of which works independently. When the first spindle tool completes the first process, the second spindle tool will run the next process according to the program settings, and the three spindles can be automatically replaced according to the engraving needs, so it is also called an automatic tool change CNC router machine. This multi-process ATC CNC router machine is very suitable for processing complex patterns on the one sheet, without the need to stop the machine for manual tool change, which greatly improves the production efficiency of the workshop.

The working area of this three-spindle CNC router machine is 1300×2500mm, and each spindle tool can reach the maximum machining area. The spindle adopts HQD, a well-known Chinese brand that has obtained CE certification. You can choose different powers for the three spindles (1.5KW-9.0KW are available) according to the needs of engraving and cutting. The choice of spindle power is related to the material thickness, character, processing technology and other factors.

Whether it is fine engraving or large-area cutting, the

CNC router machine can easily complete it, so that the processed plate pattern is fine and clear, and the cutting surface is smoother. Adopt CNC control system to cut any shape faster and more accurately.

Another advantage of the CNC router machine AKM1325R-3 is the addition of a rotary axis device on one side of the machine. This CNC router machine with a rotating axis is also known as a 4-axis router machine. Due to the rotational motion of the 4th rotation axis, the CNC router machine can realize 3D machining of cylindrical surfaces and arc surfaces. In terms of use, it can process planes, reliefs and cylinders, and has a wider range of applications.

In addition to being fixed on one side of the machine, the rotating shaft can also be placed on the CNC machine worktable. This method of use is more suitable for the case where the cylindrical material is less processed, and it can be loaded and unloaded at any time, saving space and being more convenient. It should be noted that this method needs to determine the height of the gantry according to the diameter of the rotating shaft. The larger the diameter, the higher the Z axis.

The ATC CNC router machine AKM1325R-3 is equipped with a feeding auxiliary wheel at the rear of the machine. When the workshop is processing large-area plates, auxiliary wheels can be used to feed materials, which can reduce the labor intensity of workers and improve work efficiency. Equipped with a hybrid servo motor, it has strong power and reliable performance, ensuring high-speed and stable operation of the machine.

Multi-process CNC router machine has 2-4 spindles that can be added, if your engraving and cutting work is more complex and needs more tools to complete, we recommend you to choose a CNC router machine with automatic tool changer, it can load 4-12 tools at your disposal.

To learn more about the CNC machine plans, you can communicate online.