Since ACCTEK launched its laser welding machine and laser cleaning machine, it has been well received by many users. Recently, ACCTEK once again launched an upgraded handheld

laser cleaning and welding machine. This laser equipment combines cleaning and welding functions, which can not only clean metal surface contamination, but also weld various metal materials, providing a more efficient and flexible solution for the market.

Advantages of laser cleaning and welding machine

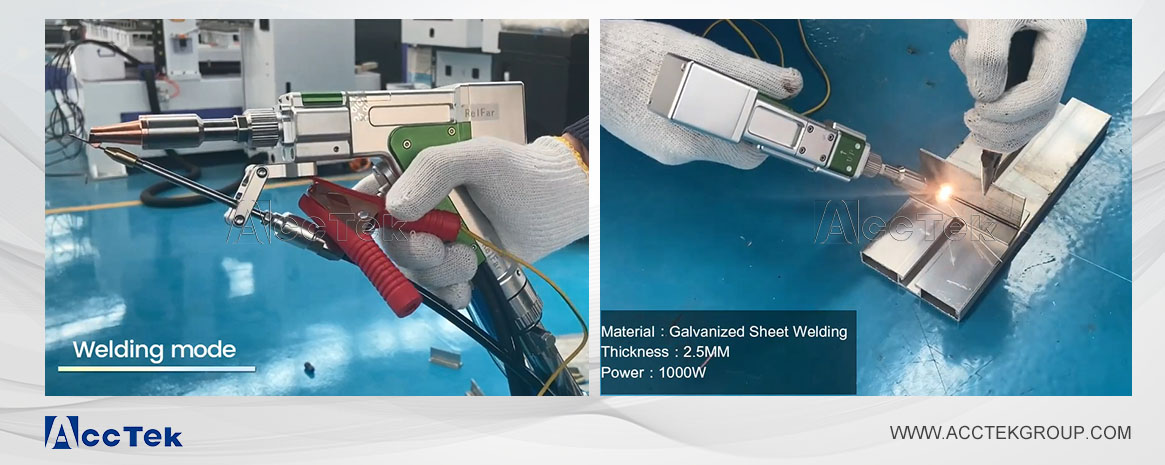

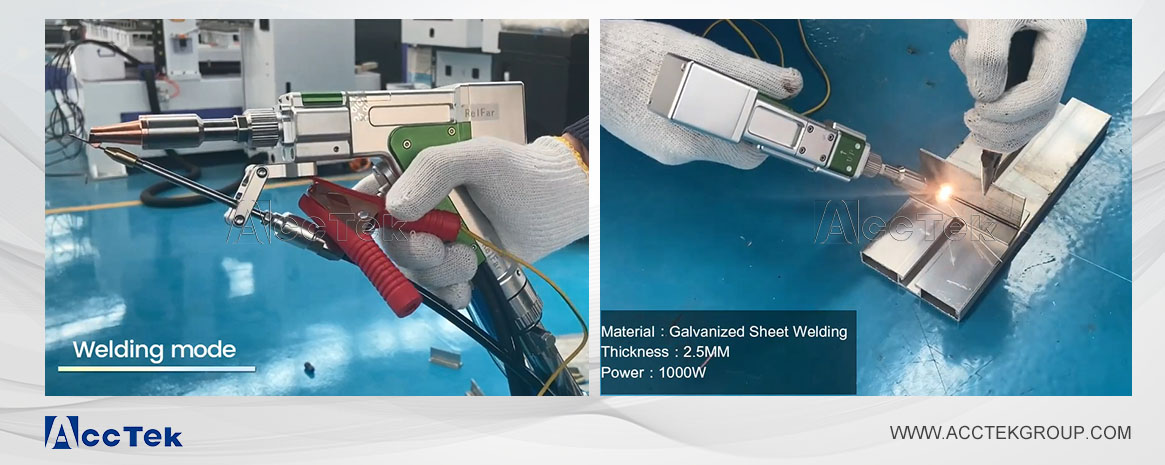

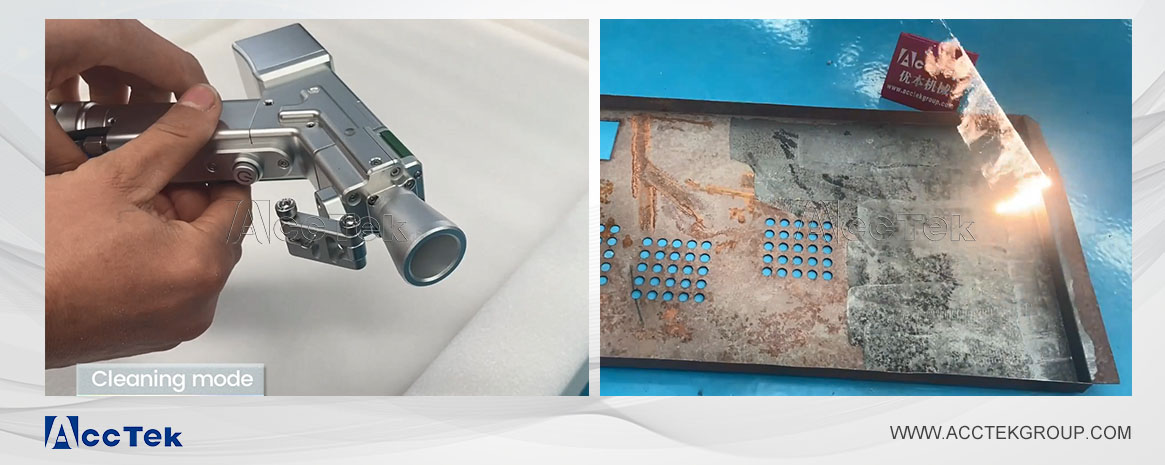

ACCTEK laser cleaning and welding machine is upgraded and added welding function on the basis of laser cleaning machine AKQ-1000. The laser cleaning welding gun adopts a hand-held design, which is comfortable to hold and can flexibly respond to various objects and angles. The laser gun is equipped with a temperature monitoring system, which can monitor the protective lens and give early warning of damage.

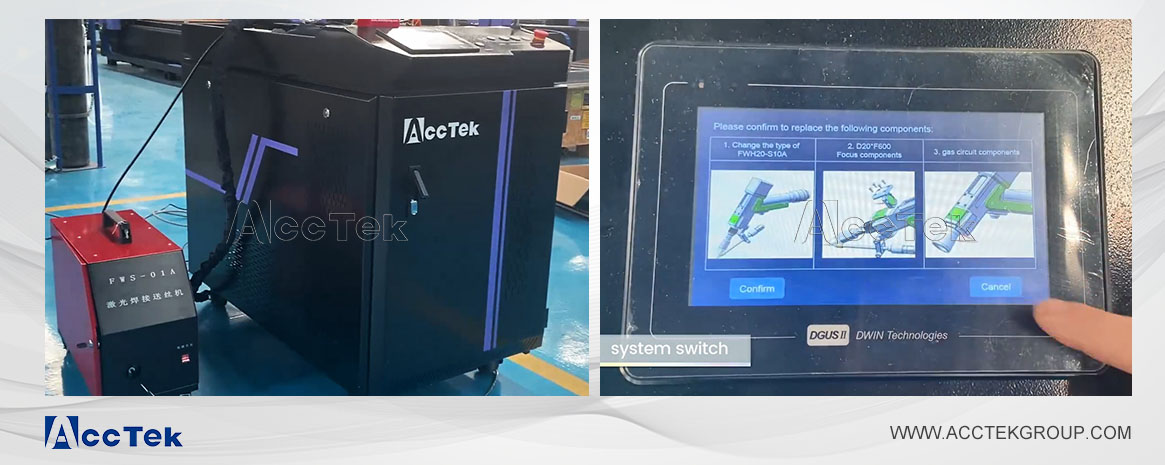

The

laser cleaning and welding machine is equipped with a Ruida control system, which has two modes of cleaning and welding, which can be flexibly switched. The system is easy to operate and can display the input and output IO status, alarm information and motion status in real time. Support a variety of different swing types, automatic wire feeding and other functions. The process parameter library is stored in the laser cleaning and welding machine. Each mode corresponds to different parameter settings. After saving, you can directly select the corresponding mode next time without setting the parameters again.

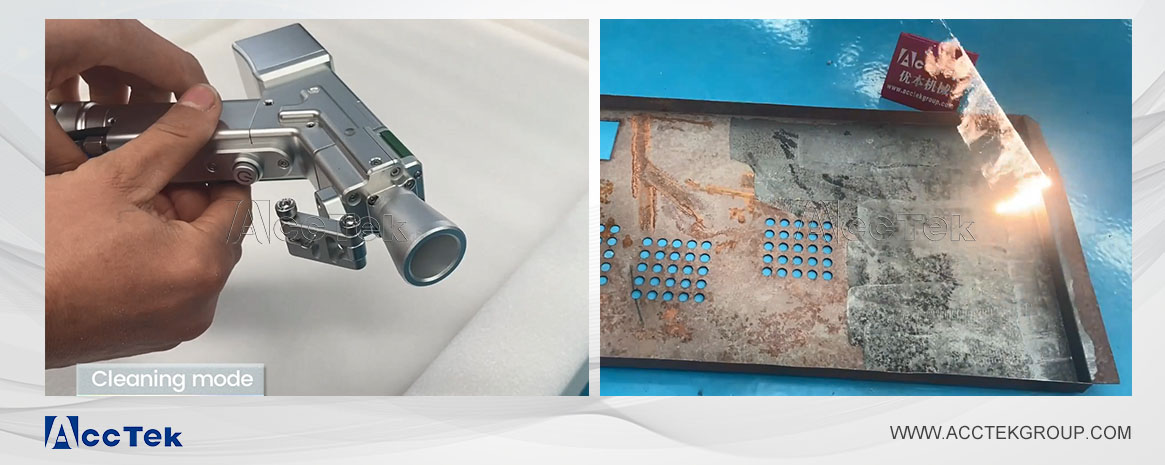

In the welding operation, the existence of galvanized layer, rust and oil pollution will increase the difficulty of welding, increase the generation of pores, and thus affect the welding effect, so a cleaning process is required before welding the metal. The traditional method is to use chemical cleaning or mechanical cleaning, which is time-consuming and labor-intensive, and also generates waste. The laser cleaning and welding machine has all the functions of the laser cleaning machine AKQ-1000, which can take into account the needs of laser cleaning before and after welding, and is convenient and efficient to help users achieve the best welding effect.

The hand-held laser cleaning and welding machine enables novice welders to master cleaning and welding operations with only a few hours of training through an intuitive and concise control system and a customizable process parameter library. Reduce labor costs while improving quality, consistency, and productivity. Laser cleaning and welding machine is an innovative product that is simple to operate, economical and intelligent. For different application scenarios, the corresponding nozzle nozzles can be easily and quickly replaced, making tedious processing simple and efficient.

Switching from traditional cleaning and welding methods to this handheld laser system allows you to balance efficiency, quality and safety. The

laser cleaning and welding machine will meet your fine processing needs.