With the wide application of

fiber laser cutting machines in the industrial market, the problems of improving metal processing efficiency and cutting accuracy have been gradually solved. At present, both stainless steel and carbon steel can be easily processed by fiber laser cutting machines. However, the cutting of aluminum or copper as a highly reflective material has always been a difficult problem for fiber laser cutting machines. In particular, aluminum, as the main raw material for the industrial market, has a wide range of applications. Therefore, how to use a fiber laser cutting machine to cut aluminum is a problem that laser machine manufacturers need to think about.

When cutting aluminum or copper, because the highly reflective metal has a very low absorptivity for laser light, the highly reflective light generated during cutting can easily damage the equipment, which is a difficult point for laser cutting. For users, cutting is the first process of the entire production line. If there is a problem with the equipment, the subsequent series of processes need to be shut down, which will have a serious impact on the entire production. Therefore, choosing a metal laser cutting machine with excellent anti-reflection ability and stable cutting is very important to the production efficiency of the enterprise.

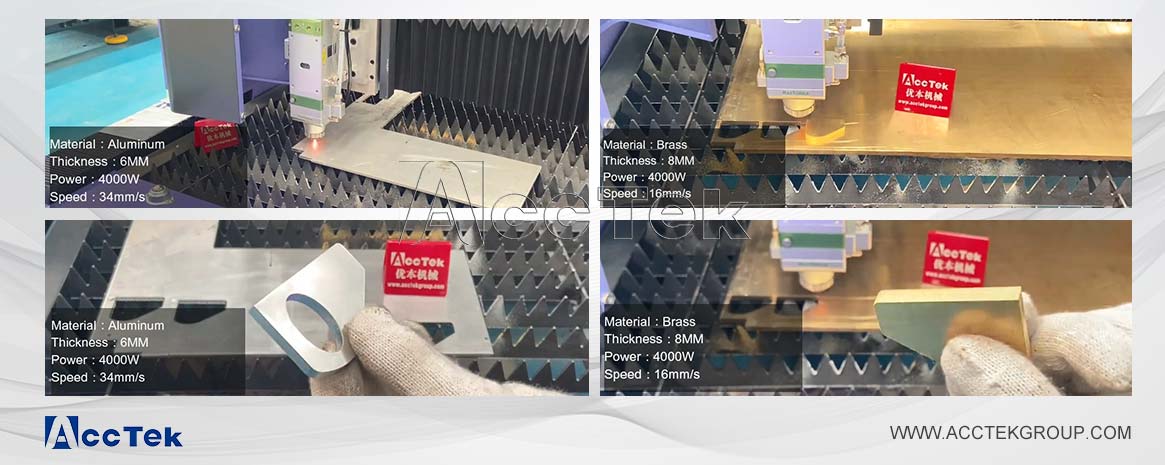

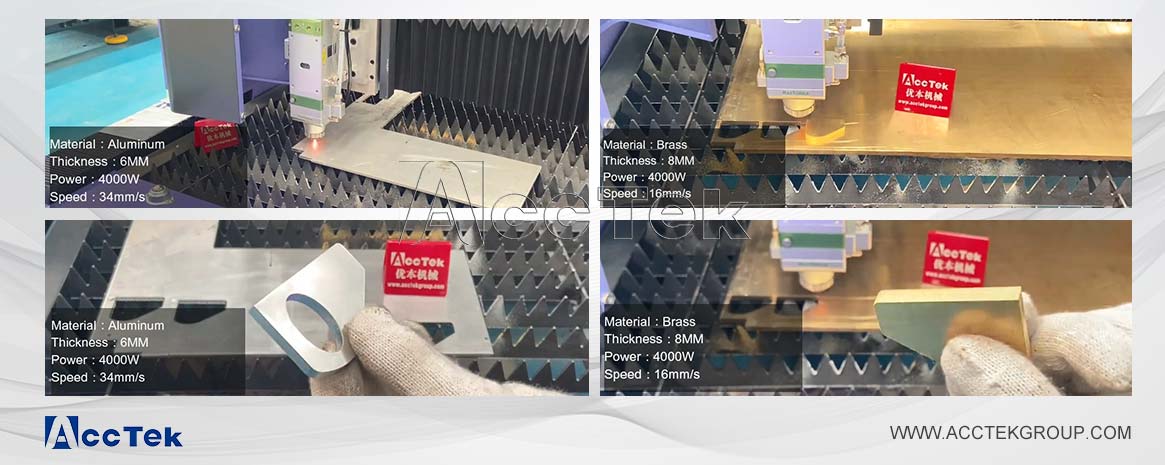

Using the correct laser cutting equipment and adjusting the correct cutting parameters can cut aluminum and copper well. The 4000W

IPG fiber laser cutting machine produced by the ACCTEK LASER factory can cut up to 10mm aluminum and 8mm copper. It is a metal laser cutting machine that can be used for batch processing of highly reflective materials. The picture below shows you the process of cutting aluminum and copper and the cutting effect. You can see that the copper and aluminum parts processed by the fiber laser cutting machine have smooth cross-sections without burrs and no slag on the bottom, and the cutting effect is very good.

If you have a high number of cuts of highly reflective materials in your metal project, then it is recommended that you choose an IPG laser generator. This 4000W IPG fiber laser cutting machine has a higher power density, which makes it easier to reach the energy density threshold, promotes the stability of the energy coupling of the laser, and perfectly solves the problem of laser cutting highly reflective metals. In addition to overcoming the difficulty of high-reflection metal cutting process, the IPG fiber laser cutting machine is also superior in processing efficiency.

After choosing a high-quality fiber laser cutting machine, you also need to pay attention to using the appropriate cutting parameters. Aluminum itself is not resistant to high temperature, and once the cutting dwell time is improper, burrs will occur. Better cutting results can be obtained by adjusting parameters such as cutting focus, speed, output power, and air pressure.

If you are inexperienced in cutting highly reflective materials, it is important that you understand the manufacturer's after-sales service capabilities before purchasing a fiber laser cutting machine. You need to be sure that when you need technical support and parameter guidance, the laser cutting machine manufacturer can provide you with effective assistance. An experienced engineer can help you become proficient in operating the machine faster and reduce your trial and error time. Correct operation can also prolong the service life of the machine and avoid failures that cause downtime or incur maintenance costs.

When machining highly reflective materials with

metal laser cutting machine, the correct use of assist gas is also a key factor in ensuring successful cutting. Nitrogen is a better choice when piercing and cutting aluminum and copper. On the one hand, nitrogen can blow away the slag and ensure the smoothness of the cutting surface. On the other hand, nitrogen is chemically inactive, and it is not easy to react with the workpiece to be oxidized, which can prevent oxidation well and ensure that the color of the cut product is uniform. It should be noted that the use of nitrogen-assisted metal cutting requires higher purity.

When cutting copper and aluminum, don't pay too much attention to the cutting speed, but more importantly, the cutting effect. How to grasp the cutting accuracy is the most important.

The development of fiber laser cutting technology has brought a new upgrade to the precision, speed and quality of sheet metal processing. The laser cutting metal process has become the first choice for advanced manufacturing industries. With the upgrading of products by laser cutting machine manufacturers, laser cutting of highly reflective materials will gradually become a common phenomenon. ACCTEK LASER has fiber laser cutting machines in the power range of 1KW-12KW to choose from. Among them, IPG fiber laser cutting machine and JPT fiber laser cutting machine can process highly reflective materials very well. For more information on fiber laser cutting of highly reflective metals, you can communicate online.